Modeling and optimization methods for wax-oil hydrogen cracking process

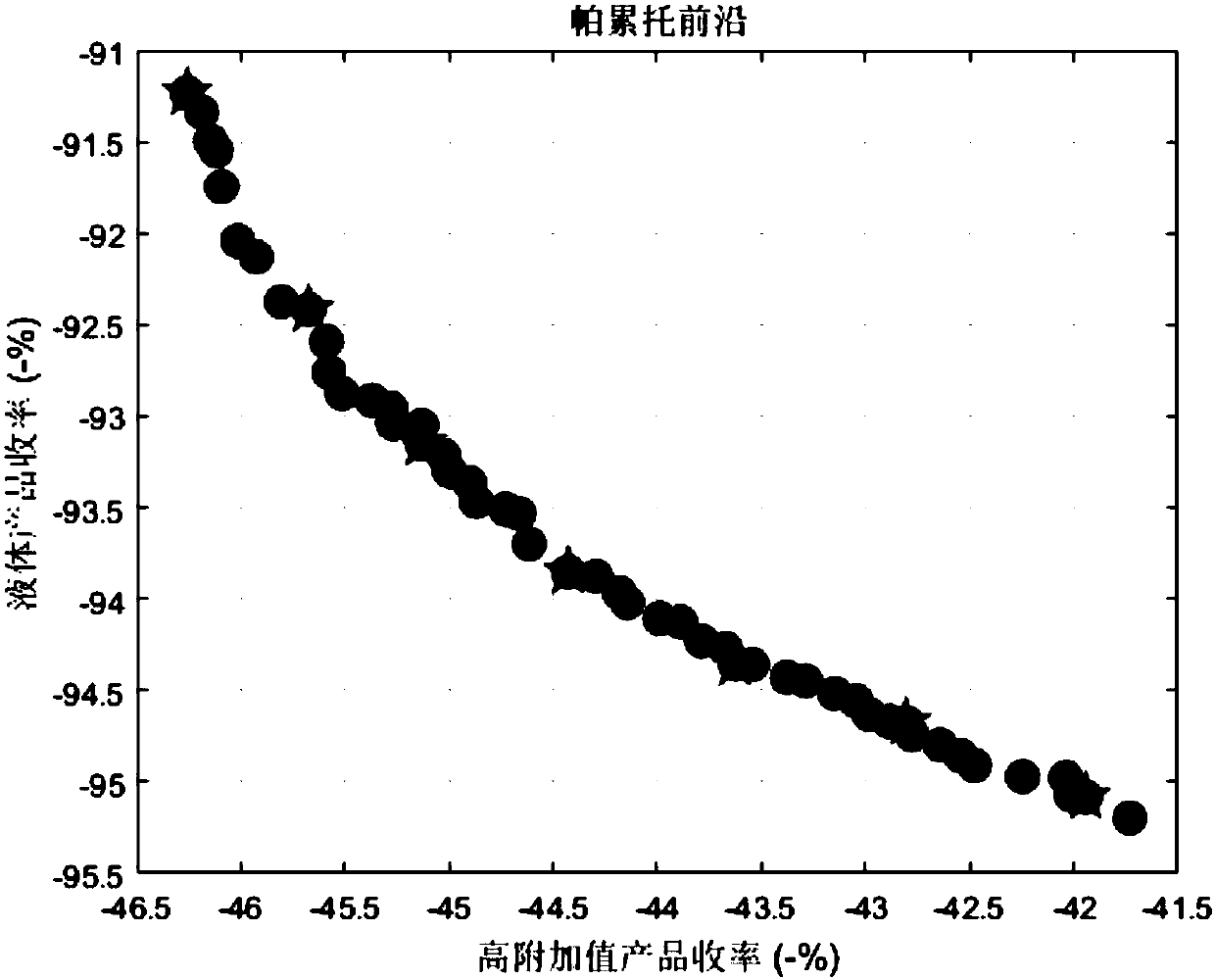

A cracking process and hydrocracking technology, applied in design optimization/simulation, CAD numerical modeling, special data processing applications, etc., can solve problems such as being too simple, unable to accurately reflect the operation of production units, and difficult to solve.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

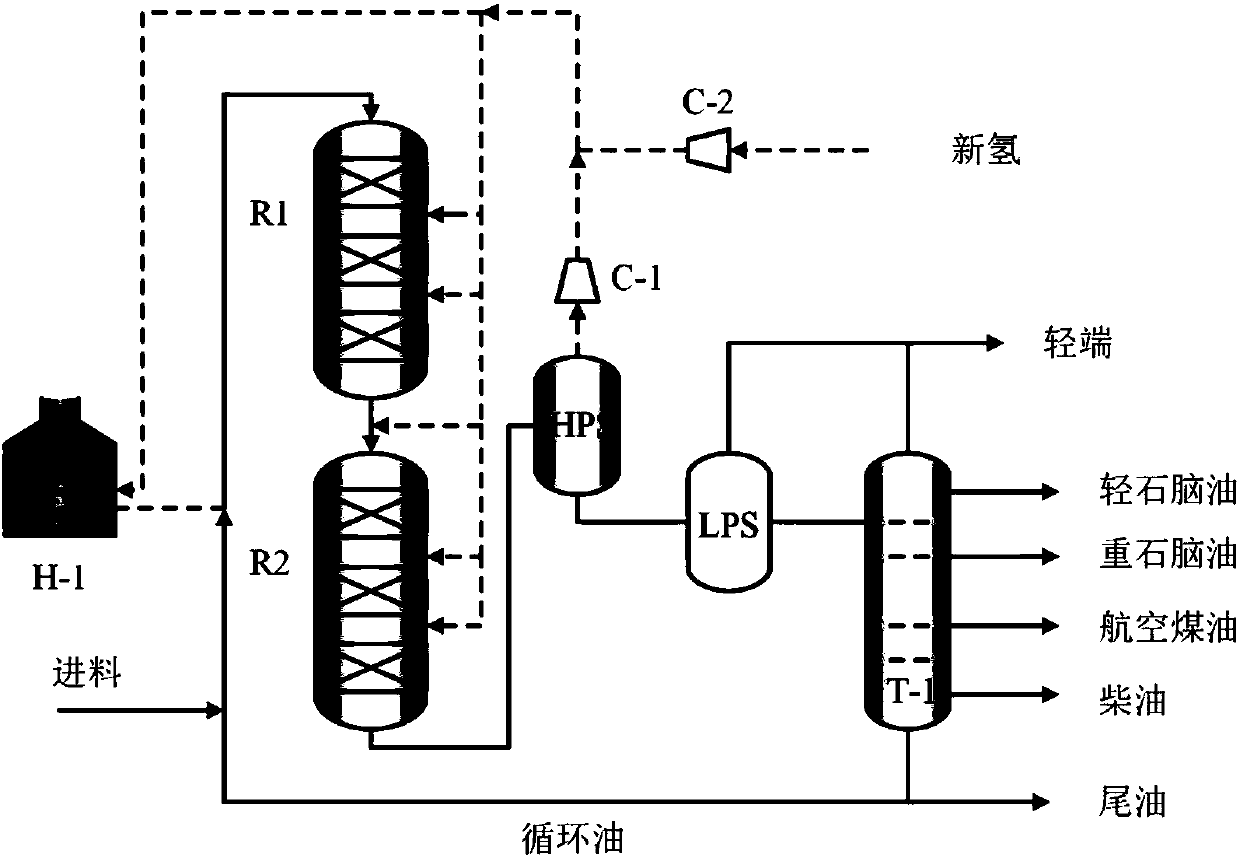

[0125] 1. Determine the parameters under the specific reaction pressure and hydrogen-oil ratio according to the industrial hydrocracking unit: including design parameters (each bed length, diameter) and operating data (feed flow rate, each bed inlet and outlet temperature, feed and product Relative density and distillation range data, product yield), and according to lump theory, raw materials and products are divided into 6 lumps.

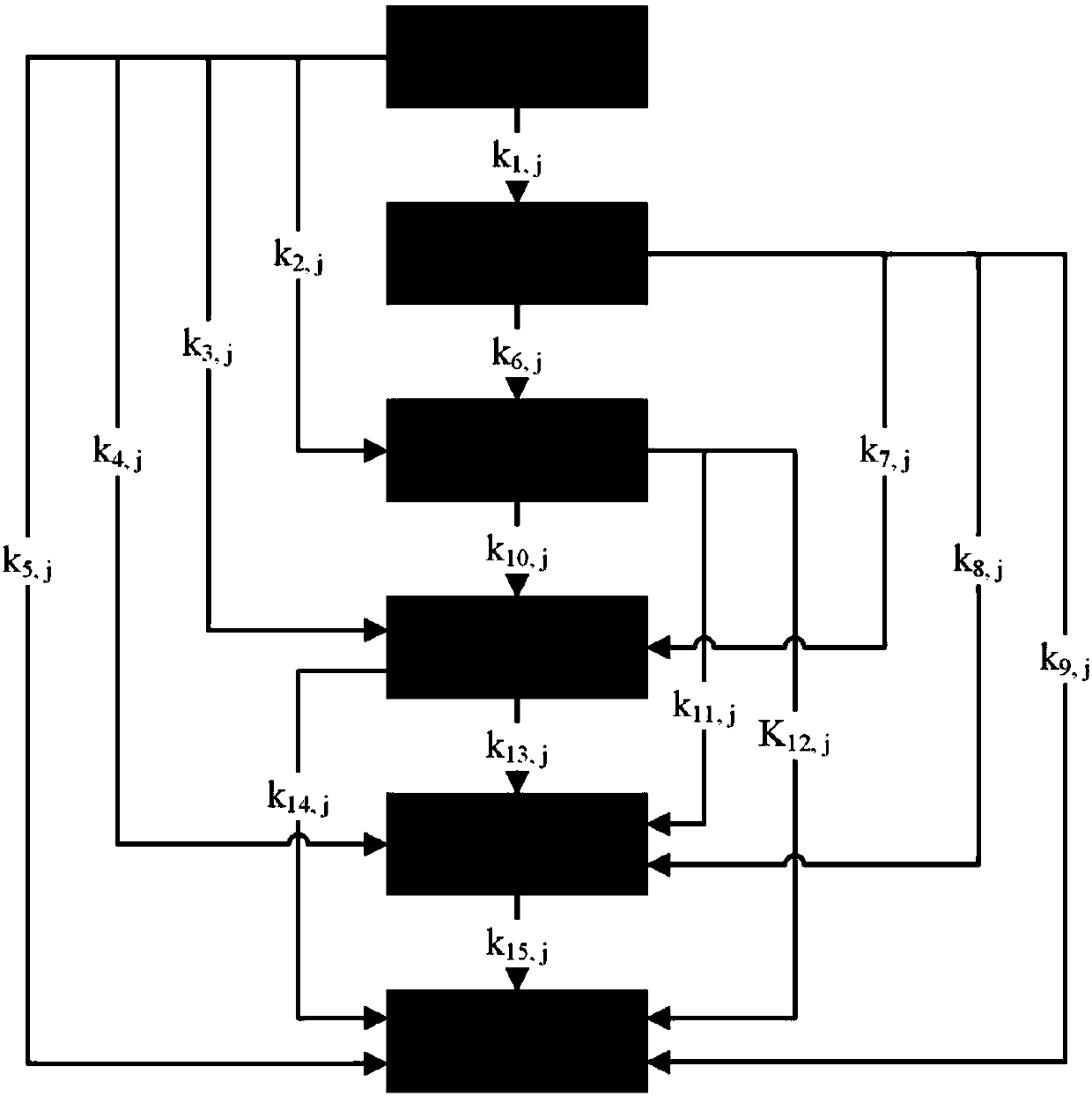

[0126] 2. Determine the hydrocracking reaction kinetic equation, material balance equation and energy balance equation. Using lump theory, considering that the reaction pressure and hydrogen-oil ratio are stable during the reaction process, and the reactant flow rate changes linearly (axially), a hydrocracking lump kinetic model is established, and the rate constant is calculated by the Arrhenius equation , the reactor is approximated as a plug flow reactor, regardless of the radial diffusion of the reactor, the reaction kinetic equation is as fol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com