Modeling and optimization method for delayed coking process of residual oil

A technology of delayed coking and residual oil, applied in special data processing applications, instruments, electrical digital data processing, etc., can solve problems such as difficulty in providing data, and achieve the effect of good optimization effect, superior convergence, and short solution time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

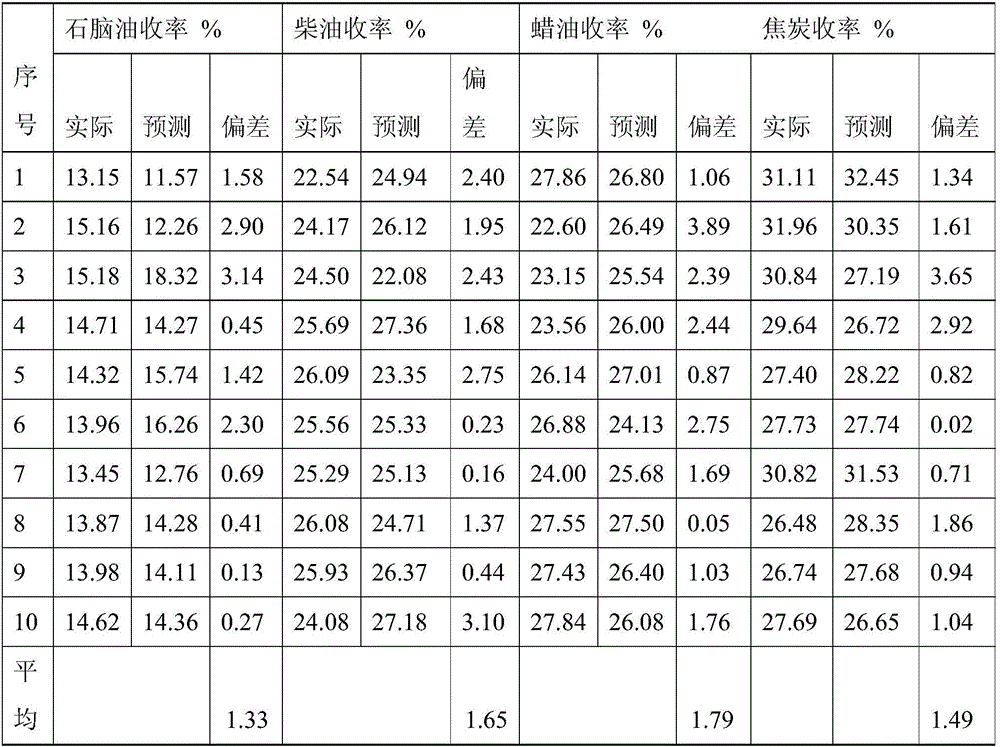

Examples

Embodiment 1

[0044] This embodiment includes the following steps:

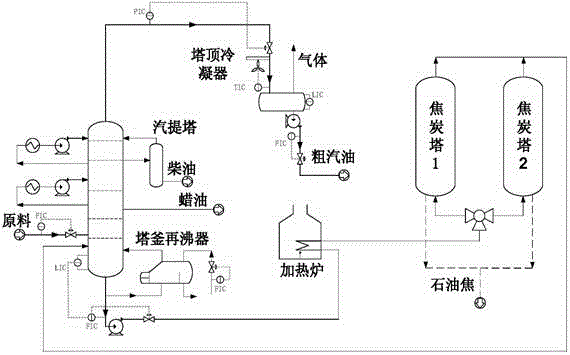

[0045] 1. Determine the parameters under specific temperature and pressure according to the industrial delayed coking unit: including design parameters (reactor length, diameter) and operating parameters (flow rate, switching time, etc.), and divide the raw materials into four sets according to the lump theory In total, the product is divided into 6 aggregates;

[0046] 2. Determine the kinetic model of delayed coking reaction

[0047] Using lump theory, considering the pressure and temperature of the reaction process are stable, a lumped kinetic model of delayed coking is established, the rate constant is calculated by the Arrhenius equation, and the reactor is approximated as a tubular reactor, regardless of the reaction The radial diffusion of the device, the product reaction rate equation is as follows:

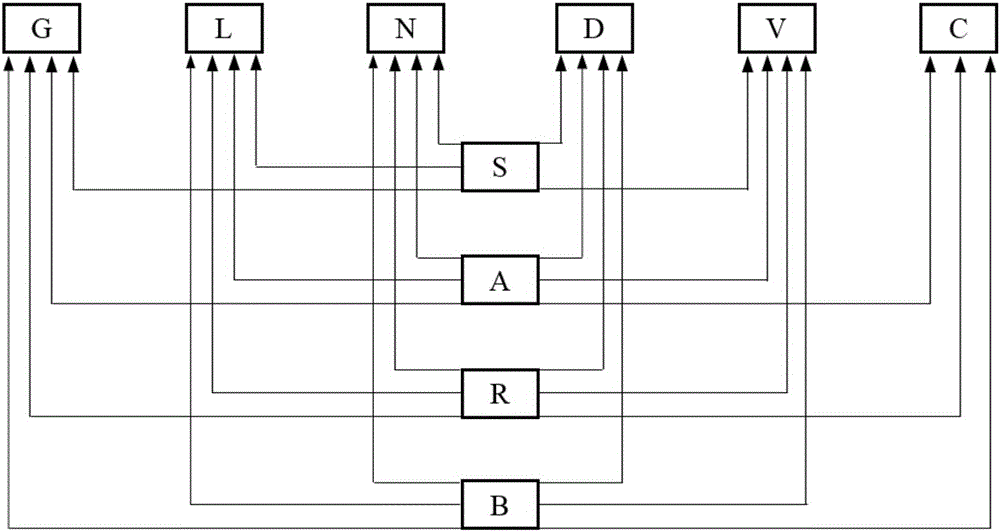

[0048] Gas: dxG / dt=k SG x S +k AG x A +k RG x R +k BG x B

[0049] Liquefied petroleum gas: dx L / dt=k...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com