Superjunction device and method of manufacturing the same

A super-junction device and pillar structure technology, which is applied in the field of semiconductor integrated circuit manufacturing, can solve the problems of difficult adjustment of output capacitance nonlinearity, large di/dt, device damage, etc., to increase softness factor, improve nonlinearity, and improve output Effect of Capacitance Characteristics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

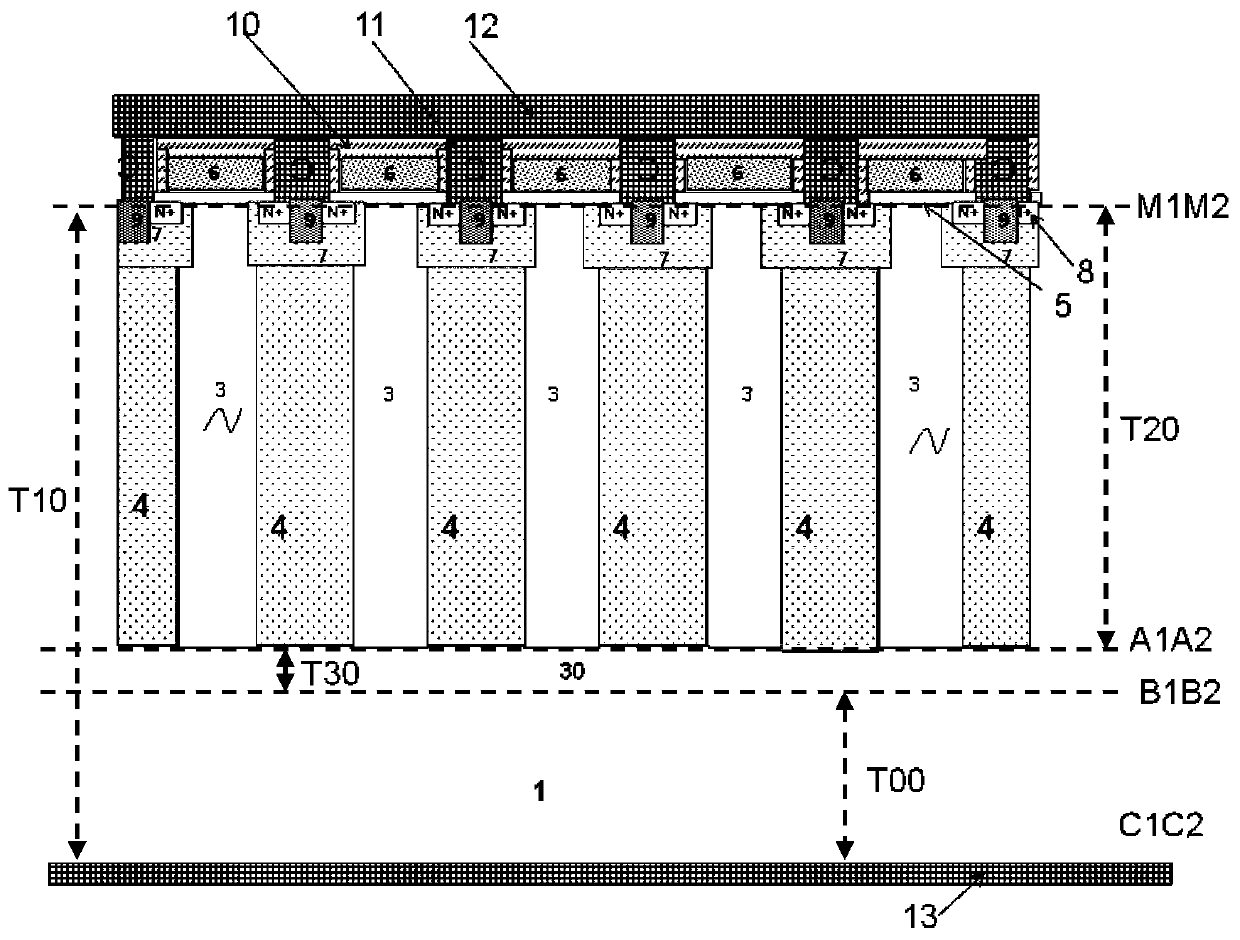

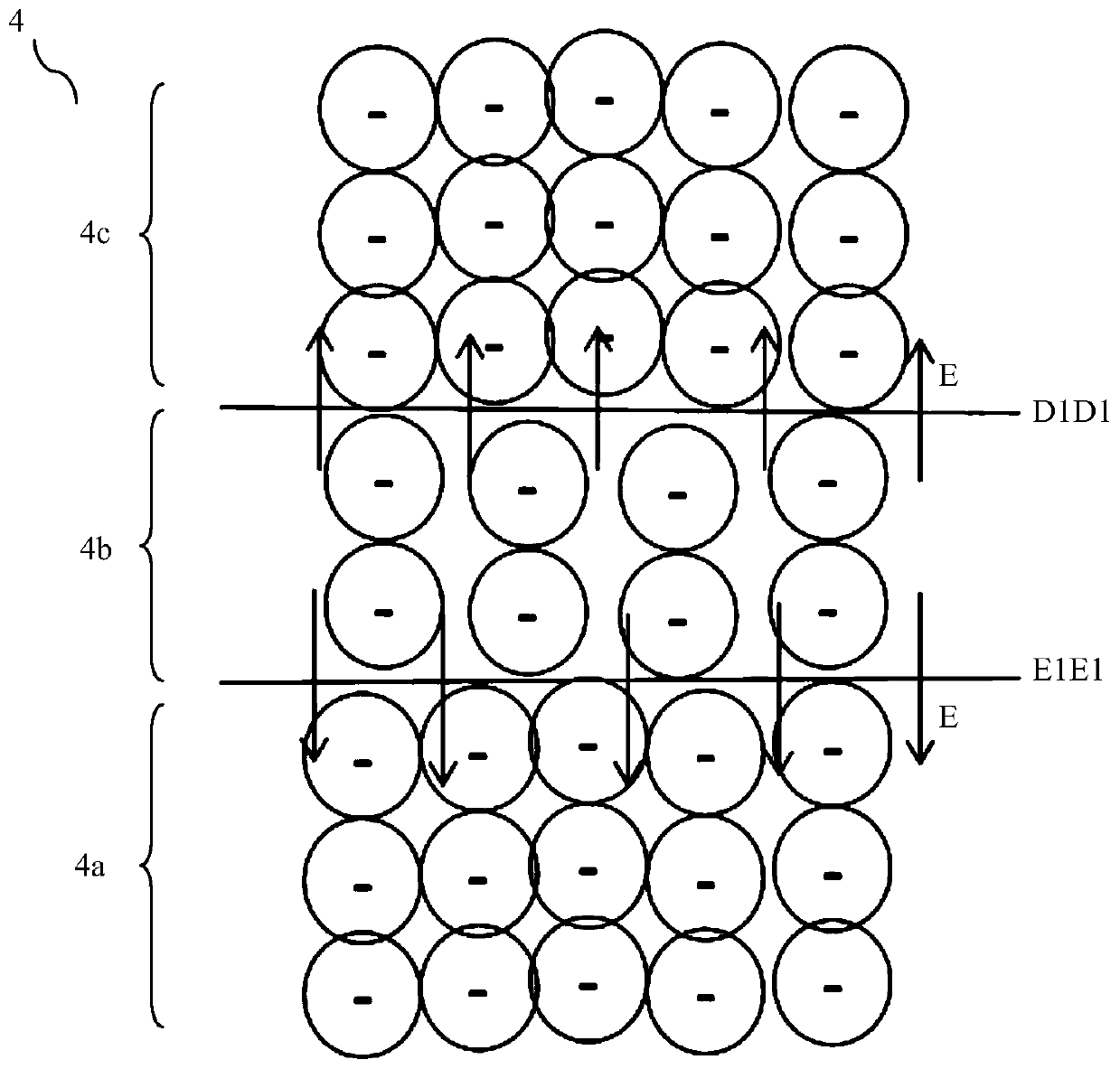

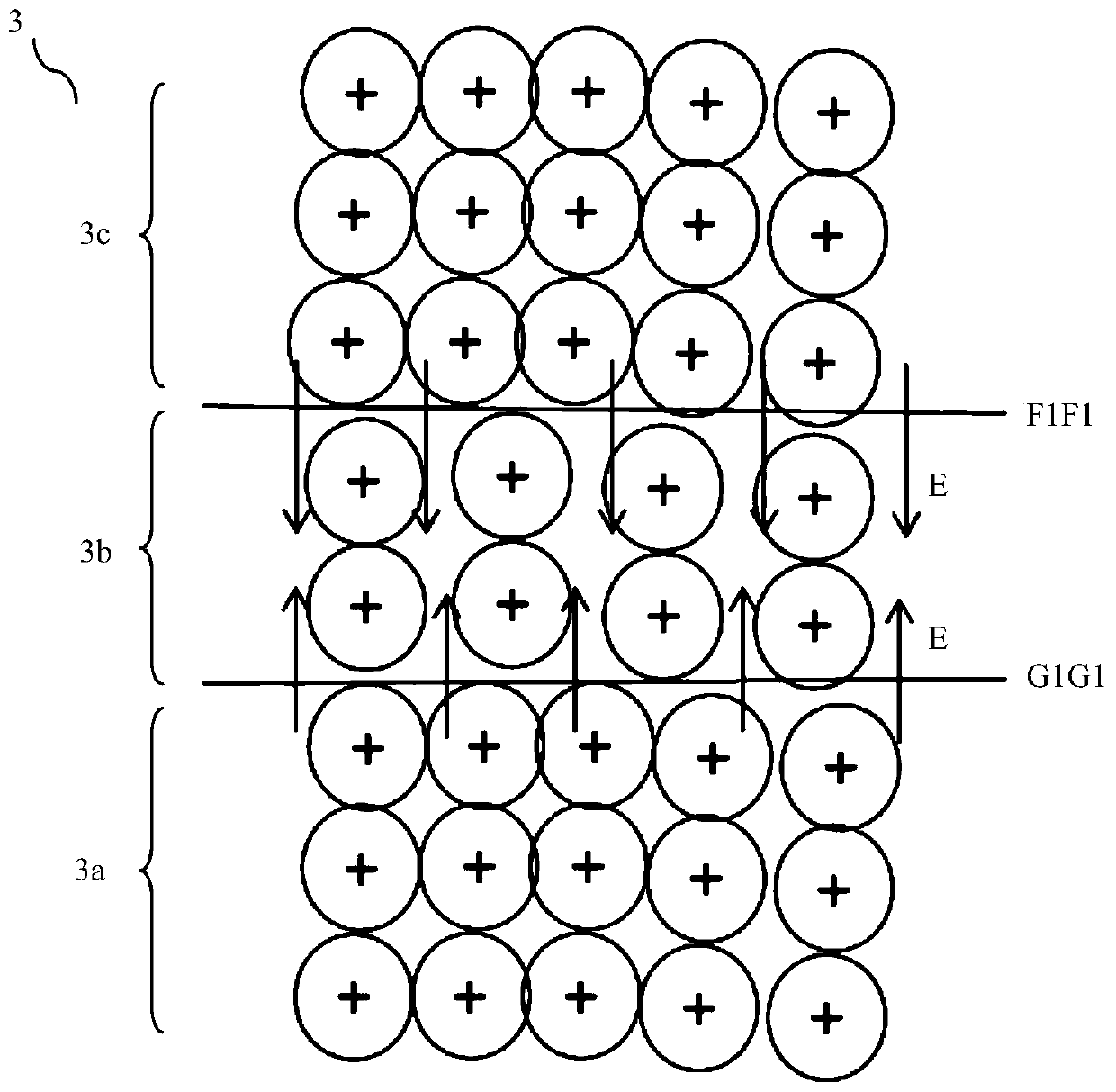

[0056] For the overall structure of the superjunction device in the embodiment of the present invention, please also refer to figure 1 As shown, the depletion structure of the P-column 4 with a longitudinal three-segment structure please refer to figure 2 As shown, the depletion structure of the N-type column 3 with a longitudinal three-segment structure please refer to image 3 As shown, the charge flow region of the superjunction device in the embodiment of the present invention includes a superjunction structure composed of a plurality of alternately arranged N-type pillars 3 and P-type pillars 4; each of the N-type pillars 3 and its adjacent The P-type pillars 4 form a super junction unit.

[0057] At least one of the N-type pillars 3 and the P-type pillars 4 of each super-junction unit has a vertical three-segment structure with doping concentration, that is, in the embodiment of the present invention, it can be divided into the following three types: Situation: the fi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical resistivity | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| electrical resistivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com