Detector, depth measurement detector unit and function depth calculation method thereof

A depth measurement and detector technology, applied in the field of detectors and depth measurement detector units, can solve the problems of discontinuous interaction depth information, difficult to control uniformity, and long time consumption, and achieve continuous interaction depth information and reduce the realization of Difficulty and cost, good effect of time resolution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

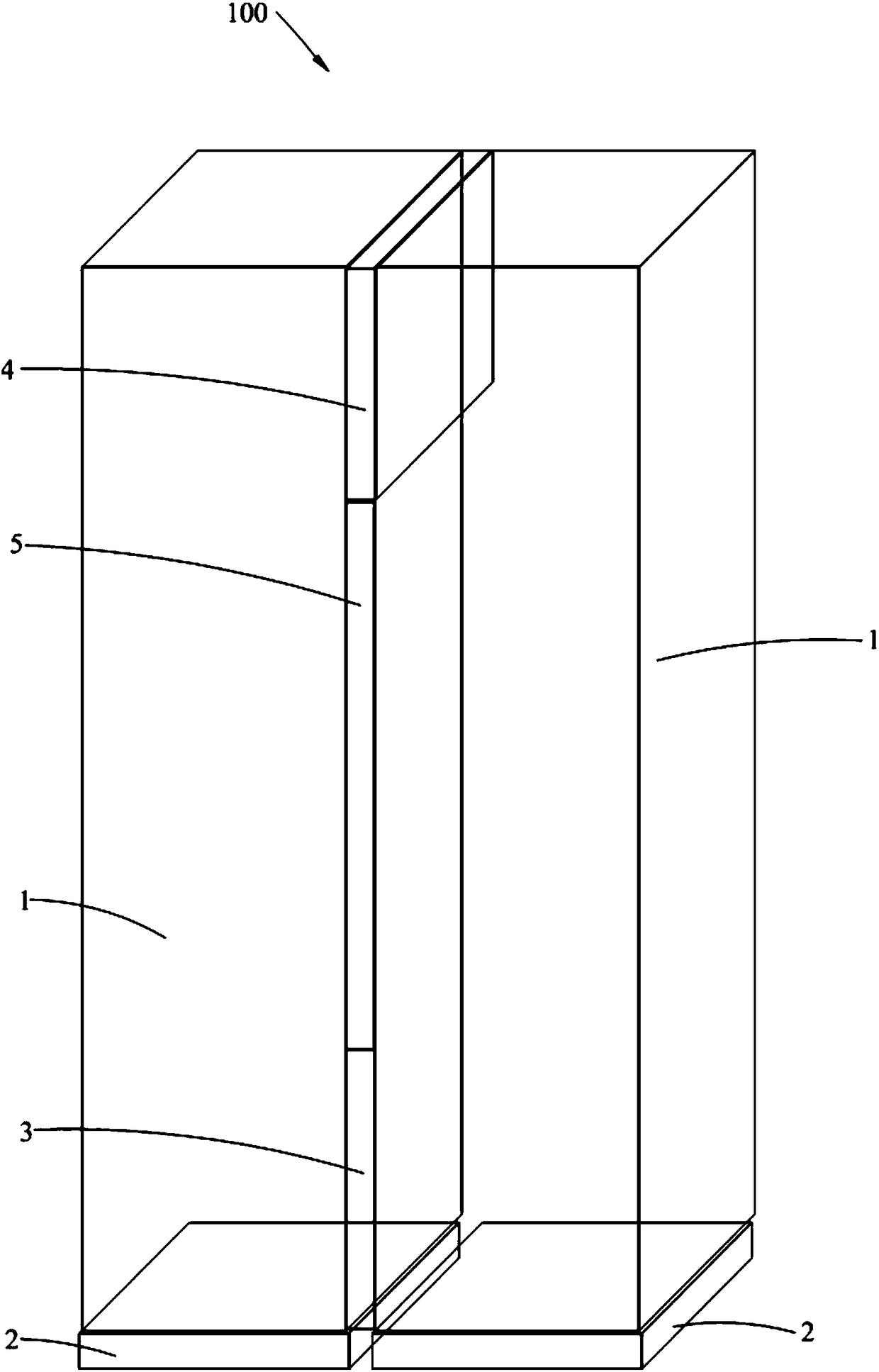

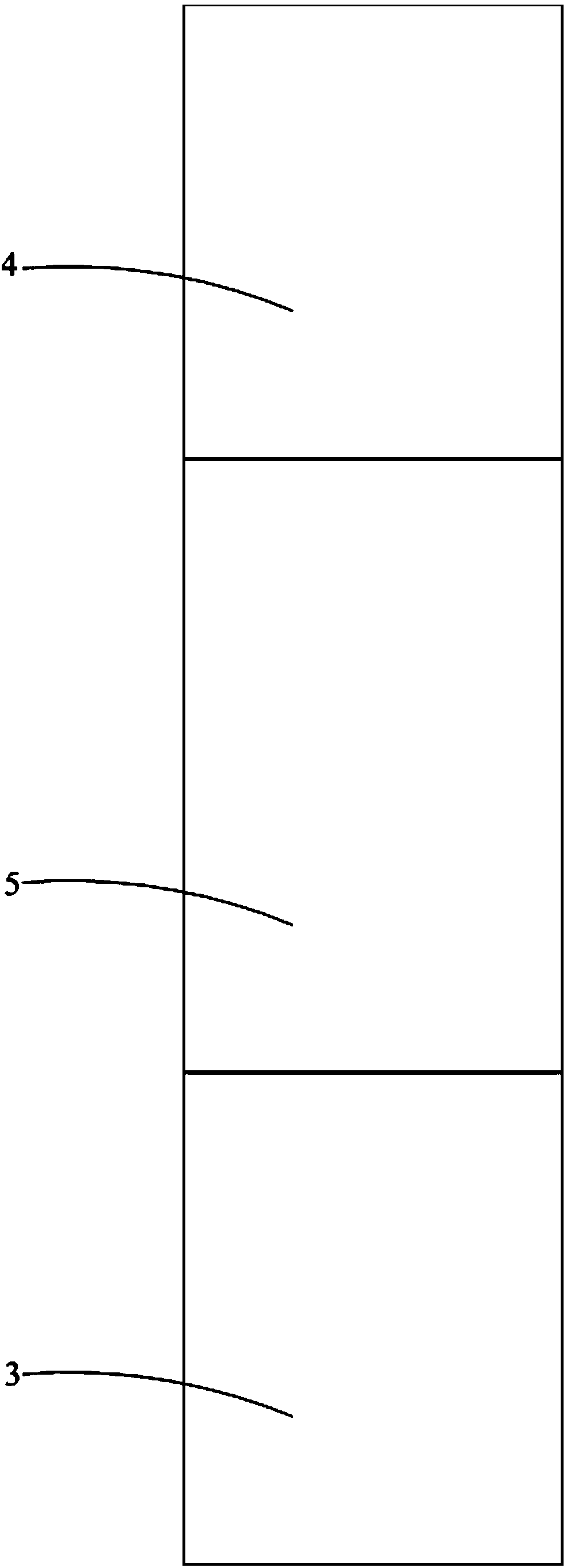

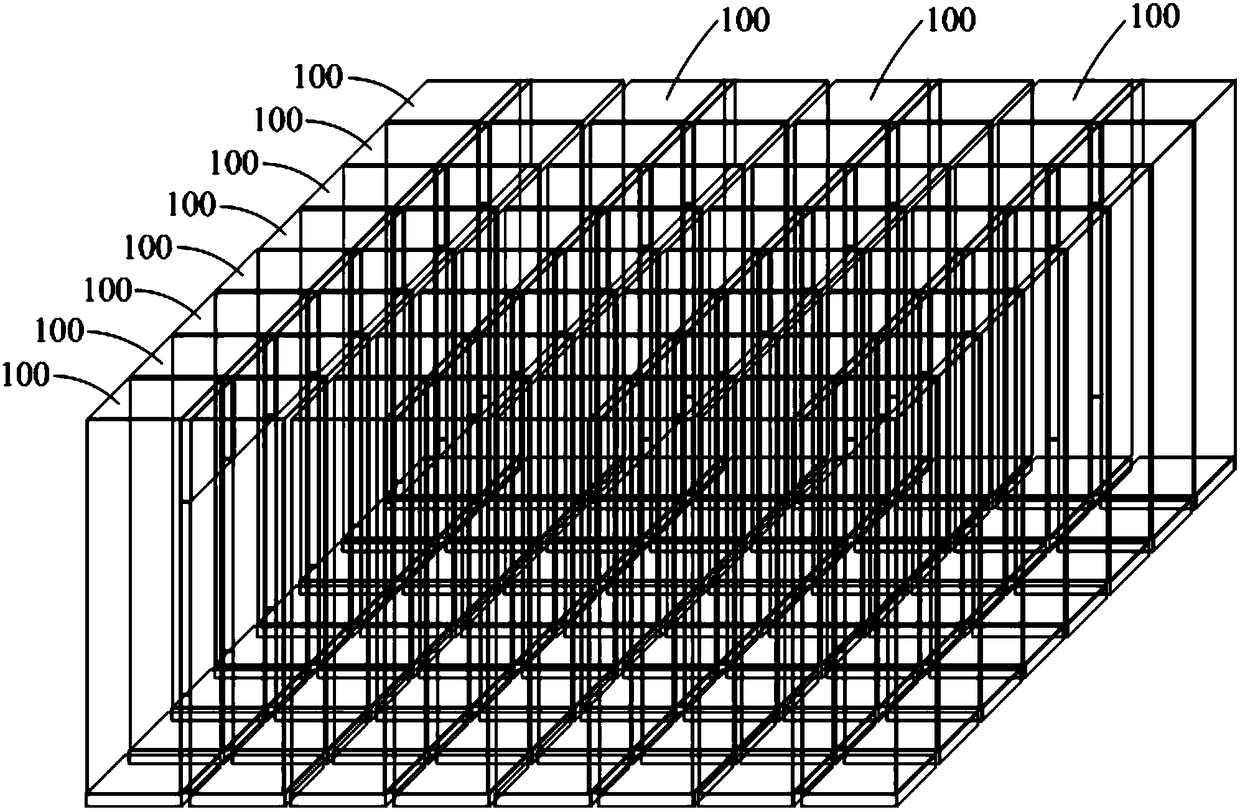

[0033] Such as Figure 1-3 As shown, the depth measurement detector unit 100 provided by Embodiment 1 of the present invention includes two scintillation crystals 1 arranged side by side at intervals and two photodetectors 2 arranged at intervals and arranged at one end of the two scintillation crystals 1 respectively. The gap between the scintillation crystals 1 includes a first layered space close to the photodetector 2, a second layered space away from the photodetector 2, and a third layered space between the first layered space and the second layered space. In the layered space, the first layered space is filled with the first reflective film 3 , the second layered space is filled with the optical coupler 4 , and the third layered space is filled with air 5 . The depth measurement detector unit 100 provided in this embodiment is coupled in different positions between two identical scintillation crystals 1 by using the first reflective film 3, the air 5 and the optical cou...

Embodiment 2

[0052] The difference between the depth measuring detector, the detector and the working depth calculation method of the depth measuring detector unit 100 provided in this embodiment and the first embodiment is that the filling material in the third layered space is different, which is specifically reflected in: Such as Figure 1-3 As shown, in Embodiment 1, the air 5 is completely filled in the third layered space, that is, the middle part between the two scintillation crystals 1 is not treated, and is only isolated by air 5; Figure 4 As shown, in this embodiment, the third layered space is filled with air 5 and the second reflective film 6, that is, the middle part between the two scintillation crystals 1 is separated by air 5 and a third reflective film is additionally added. membrane. In this embodiment, since different materials are also used to couple at different positions between two identical scintillation crystals 1, it is possible to distinguish the degree of ligh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com