On-line fully-automatic Logo press-fit overturning machine

A turning machine and fully automatic technology, applied in labeling machines, labels, packaging, etc., can solve problems such as prone to work-related injuries, high labor intensity, and easy fatigue of personnel, so as to improve quality stability, reduce labor costs, and save manpower Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] In order to make the above-mentioned features and advantages of the present invention more comprehensible, the following specific embodiments are described in detail with reference to the accompanying drawings, but the present invention is not limited thereto.

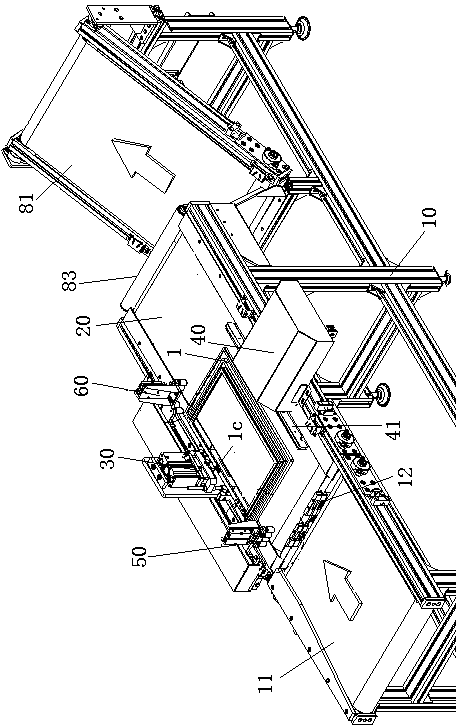

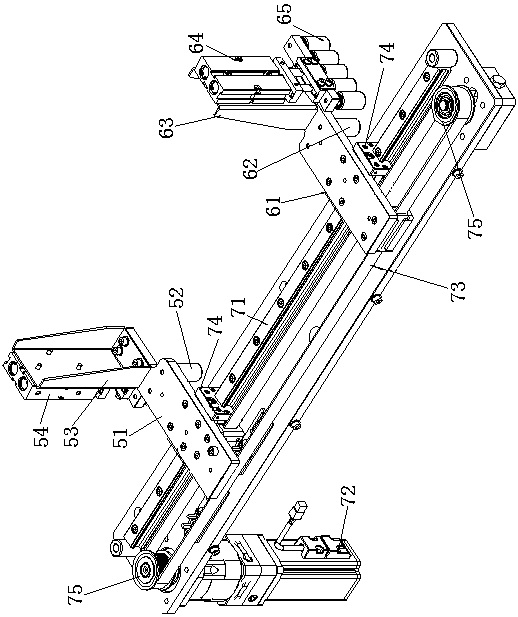

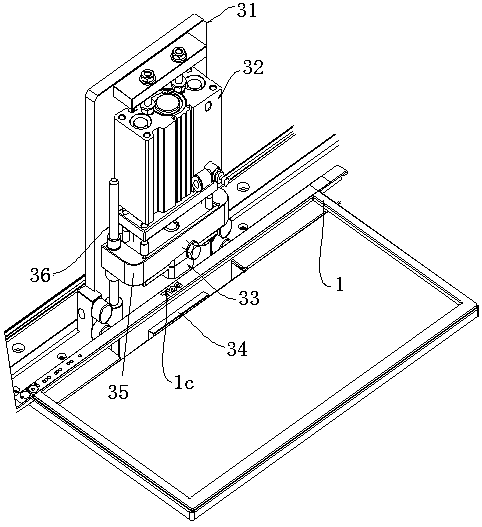

[0020] refer to Figure 1 to Figure 4

[0021] An online fully automatic Logo pressing and flipping machine, which is controlled by PLC programming, servo motor and frequency converter, and is equipped with touch screen operation. Comprising a frame 10, the frame is horizontally provided with a belt conveying platform 20 for positioning the product 1, the belt conveying platform is driven by a stepper motor 21, and the belt conveying platform is provided with a belt conveying platform for making the product move toward the belt conveying platform. The normalization and positioning device that completes the normalization on the side, and the middle part of one side of the flat belt conveying platform is also equ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com