A kind of wetting agent and its application

A technology of sizing agent and lubricant, which is applied in the field of sizing agent for non-alkali glass fiber direct yarn for pressure vessels, to achieve the effects of easy dispersion, improved burst strength and fatigue resistance, and high burst strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

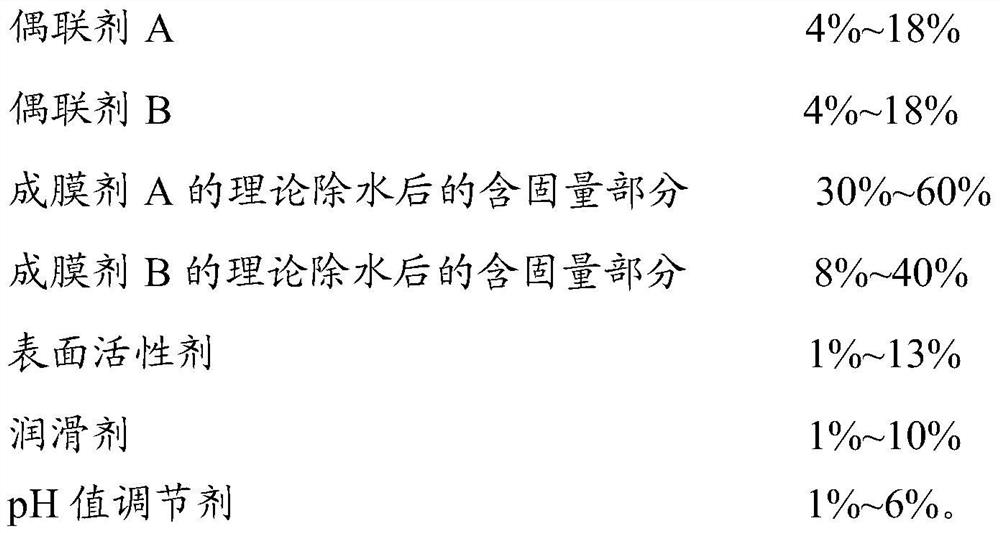

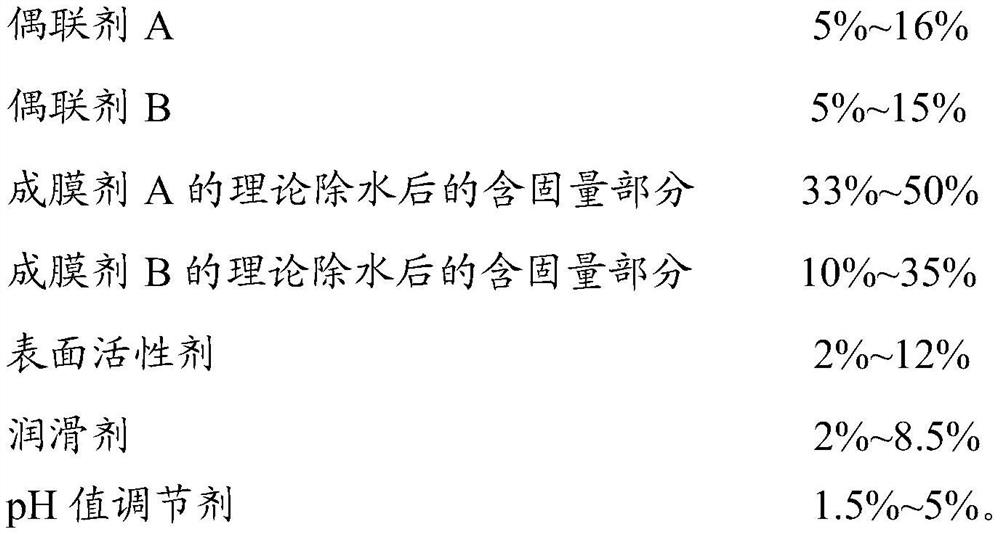

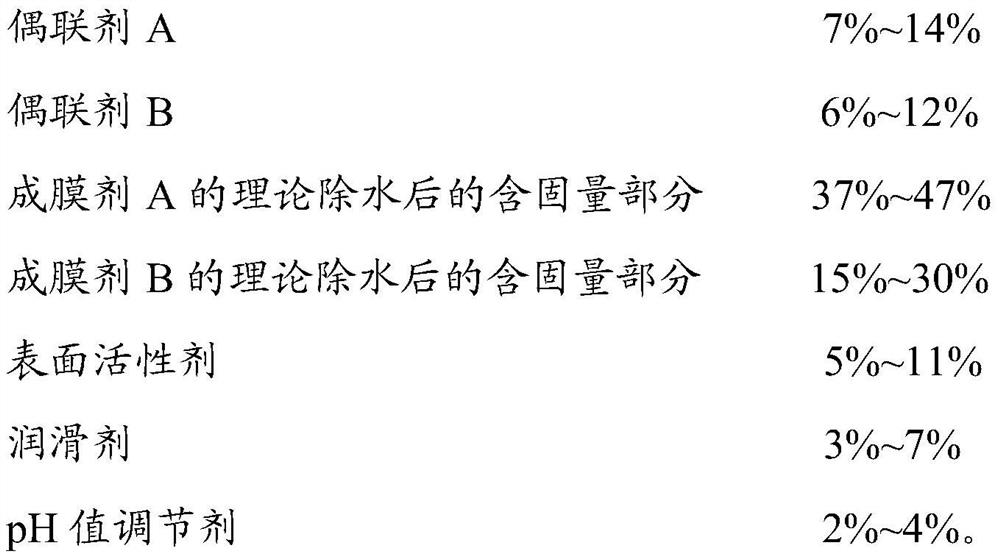

Method used

Image

Examples

Embodiment 1

[0045] Weigh each component by mass percentage, use the epoxy silane coupling agent with the brand A-187, use the vinyl silane coupling agent with the brand A-174, A-172, use the amino acid with the brand A-1100 Silane coupling agent; use grades of PEG lubricants of PEG400, PEG600, PEG800, and PEG1000; use grades of acrylic modified epoxy resin emulsions of QX-004; use grades of water-based epoxy resin emulsions of MU-609; use The brand name is AMQB-1827 cationic surfactant. Each component is carried out the preparation of non-alkali glass fiber direct yarn sizing agent for pressure vessels according to the following steps:

[0046] 1S Dilution of film-forming agent, surface active agent and lubricant: take the solid content part after the theoretical water removal of the acrylic modified epoxy resin emulsion based on the total amount of non-water component sizing agent of 33%, add the mass of Acrylic modified epoxy resin emulsion quality 1 ~ 3 times the water stirring diluti...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| bursting strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com