Manufacturing method and equipment of unequal-section bimetal transmission part

A manufacturing method and technology of transmission parts, applied in metal processing equipment, manufacturing tools, welding equipment, etc., can solve the problems of long processing time, high material consumption, high cost investment, etc., and achieve the effect of surface structure wear resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

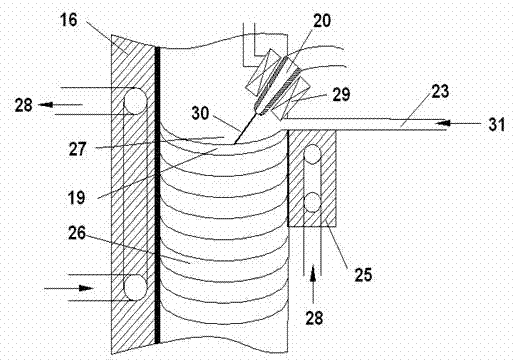

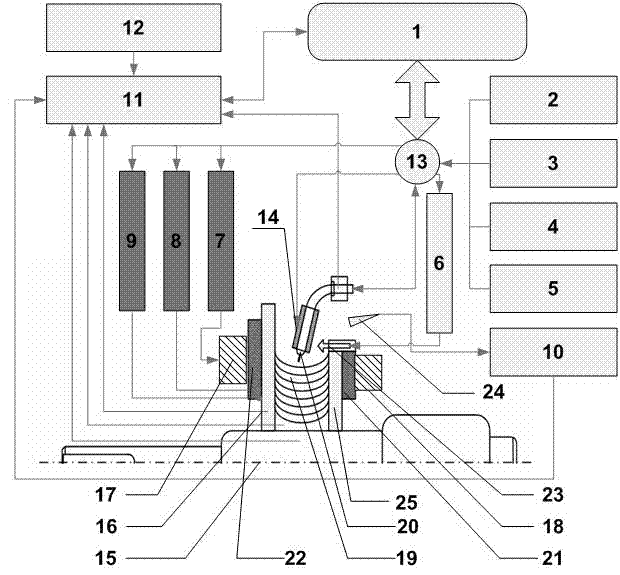

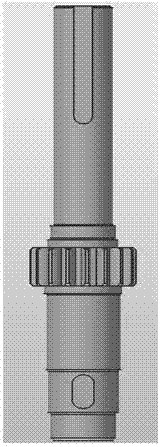

[0024] figure 1 It is a schematic diagram of welding manufacturing method and equipment of the present invention, figure 2 It is a longitudinal sectional view of the welding puddle of the present invention, image 3 It is a schematic diagram of the transmission gear shaft manufactured according to the embodiment of the present invention.

[0025] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

[0026] 1. Manufacturing method of bimetal transmission parts with unequal cross section.

[0027] The present invention is a manufacturing method of a bimetallic transmission part with unequal cross-section. On the transmission part base 15 with a small-diameter cross-section, the composite belt mold in the external field is used to force the sequential growth of the integral welding rapid prototyping technology with temperature control, combined with the in-situ alloying gradient The functional structure preparat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com