Application of a low burning rate high energy butylated hydroxyl propellant and cycloaliphatic diisocyanate

A technology of butylated hydroxy propellant and diisocyanate, applied in the field of solid rocket propellant and missile weapons, can solve the problems of inability to meet high-performance missile weapon models, and achieve the effects of good aging performance, lowering the basic burning rate, and reducing the amount of addition.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

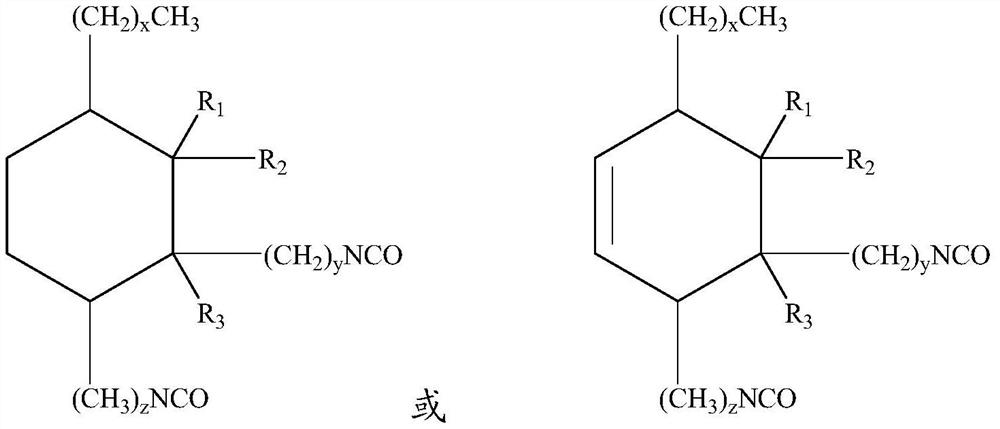

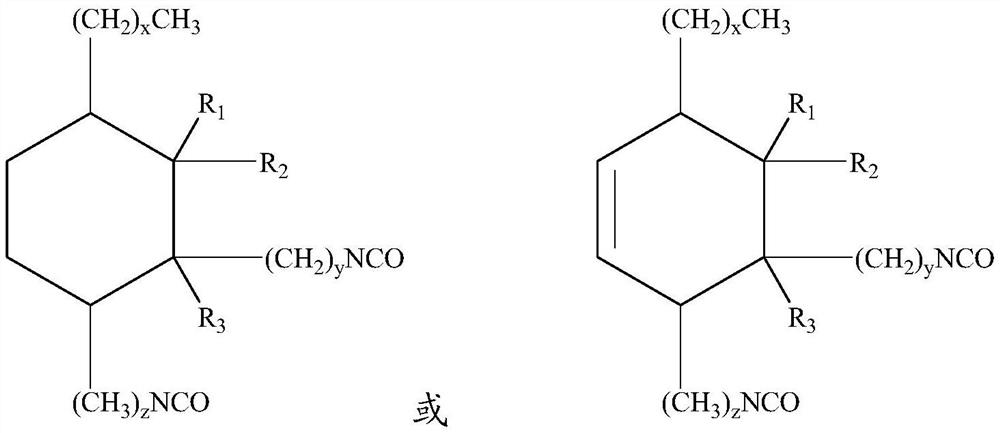

Method used

Image

Examples

Embodiment 1

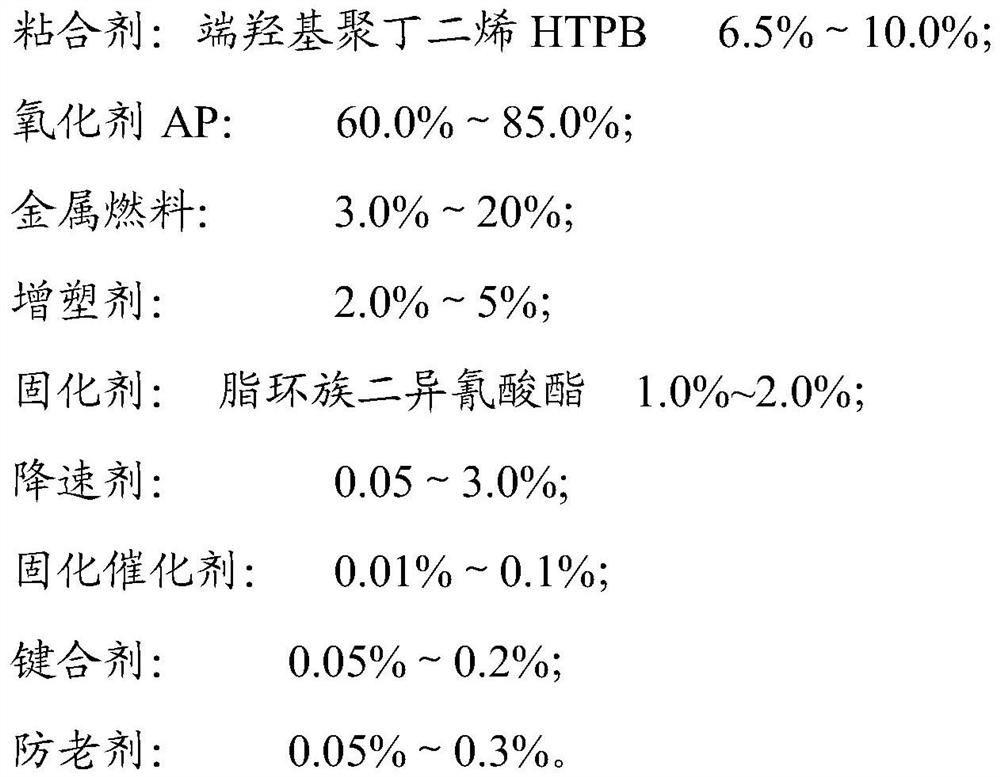

[0047] The formula (mass percentage) of general low burning rate butylated hydroxyl propellant and the low burning rate high energy butylated hydroxyl using alicyclic diisocyanate as curing agent is shown in Table 1:

[0048] Table 1 The formula of low burning rate and high energy butylated hydroxyl

[0049]

[0050] As can be seen from Table 1, the curing agent TDI in the original low burning rate butyl hydroxy propellant formula (1#) becomes 1- Butyl-2-hexyl-3,4-bis(isocyanate nonyl)cyclohexane, since the reactivity of this type of alicyclic diisocyanate is lower than that of TDI, a curing catalyst tris(3-ethane) has been added to the improved formulation Oxyphenyl) bismuth.

[0051] Table 2 shows the combustion properties of the propellants measured after the two low-burning-rate butylated hydroxybutyl propellant formulations are cured.

[0052] Table 2 Combustion performance of propellant

[0053]

[0054]

[0055] As can be seen from Table 2, with 1-butyl-2-he...

Embodiment 2

[0057] The formula (mass percentage) of general low burning rate butylated hydroxyl propellant and the low burning rate high energy butylated hydroxyl using alicyclic diisocyanate as curing agent is shown in Table 3:

[0058] Table 3 The formula of low burning rate and high energy butylated hydroxyl

[0059]

[0060] As can be seen from Table 3, there are three main differences between the original low-burning-velocity-butylated-hydroxyl propellant formula (3#) and the improved low-burning-rate high-energy butylated-hydroxyl propellant (4#): The curing agent is changed from TDI to 1-pentyl-2-nonyl-3,4-bis(isocyanatoheptyl)cyclohexane; the second is that due to the low reactivity of this type of alicyclic diisocyanate, it is added in the formula Three (ethoxyphenyl) bismuth is used as the curing catalyst; the third is that the amount of the inert deceleration agent LiF in formula 3# is reduced from 1.0% to 0.1%.

[0061] The theoretical calculation of the energy performance...

Embodiment 3

[0066] The formula (mass percentage) of general low burning rate butylated hydroxyl propellant and the low burning rate high energy butylated hydroxyl using alicyclic diisocyanate as curing agent is shown in Table 5:

[0067] Table 5 The formula of low burning rate and high energy butylated hydroxyl

[0068]

[0069]

[0070] It can be seen from Table 5 that the main change between the original low-burning-velocity-butylated hydroxybutyl propellant formulation (5#) and the improved low-burning-rate high-energy butylated-hydroxyl propellant (6#) is that the curing agent is replaced by IPDI Becomes 1-hexyl-2-propyl-3-isocyanatobutyl-4-isocyanatoheptylcyclohexane. Table 6 shows the combustion properties of the propellants measured after the two low-burning-rate HBR propellant formulations are cured.

[0071] Table 6 Various properties of the propellant

[0072]

[0073] As can be seen from Table 6, the low burning rate propellant formulation (6#) with 1-hexyl-2-propyl-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com