Polyimide film manufacturing method and polyimide film

The technology of a polyimide film and a manufacturing method is applied in the manufacture of polyimide film, the manufacturing method of polyimide film and the field of polyimide film, and can solve the problems of accumulated heat of flexible printed circuit boards and the like , to achieve high thermal conductivity and improve the effect of accumulated heat

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

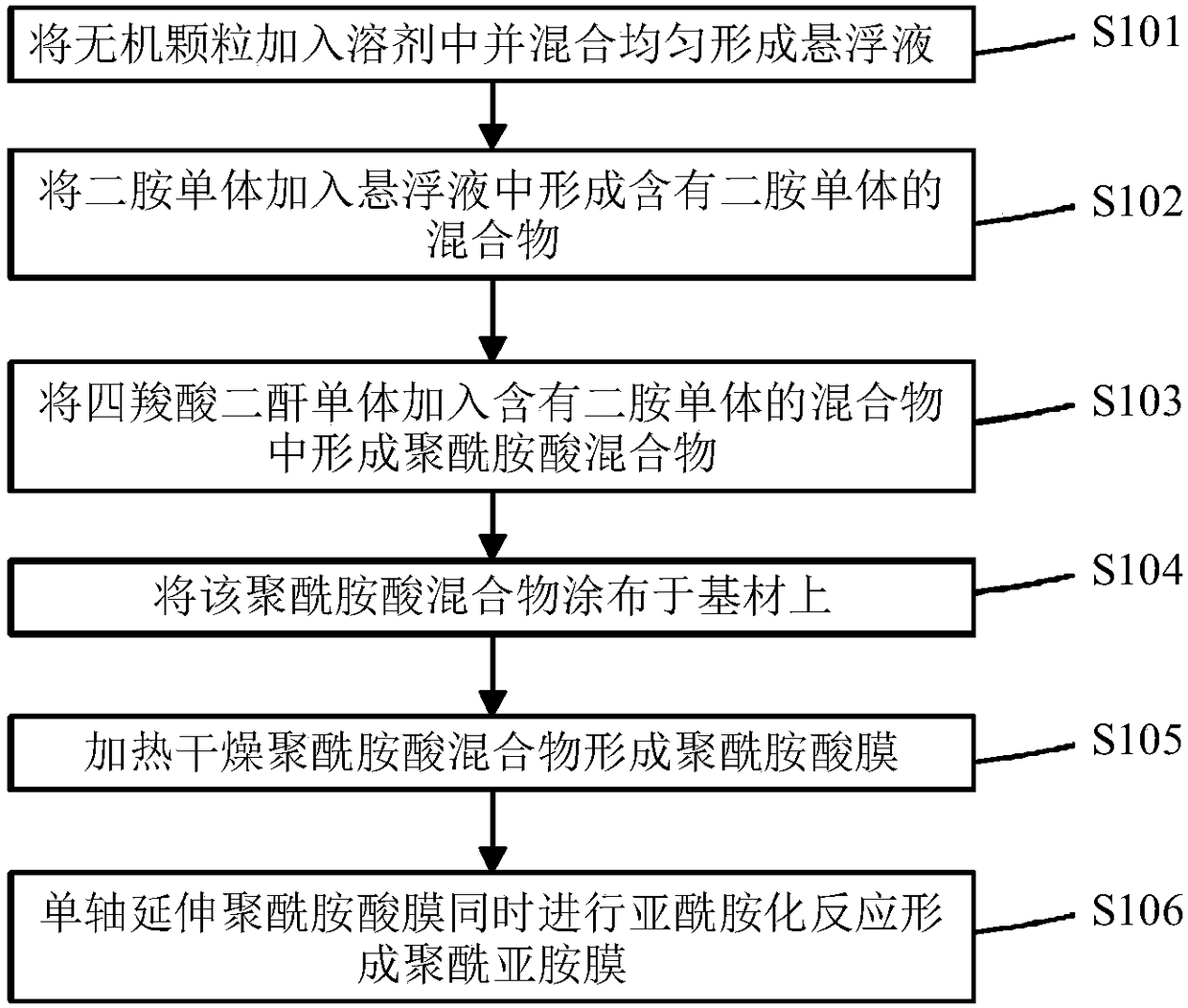

Method used

Image

Examples

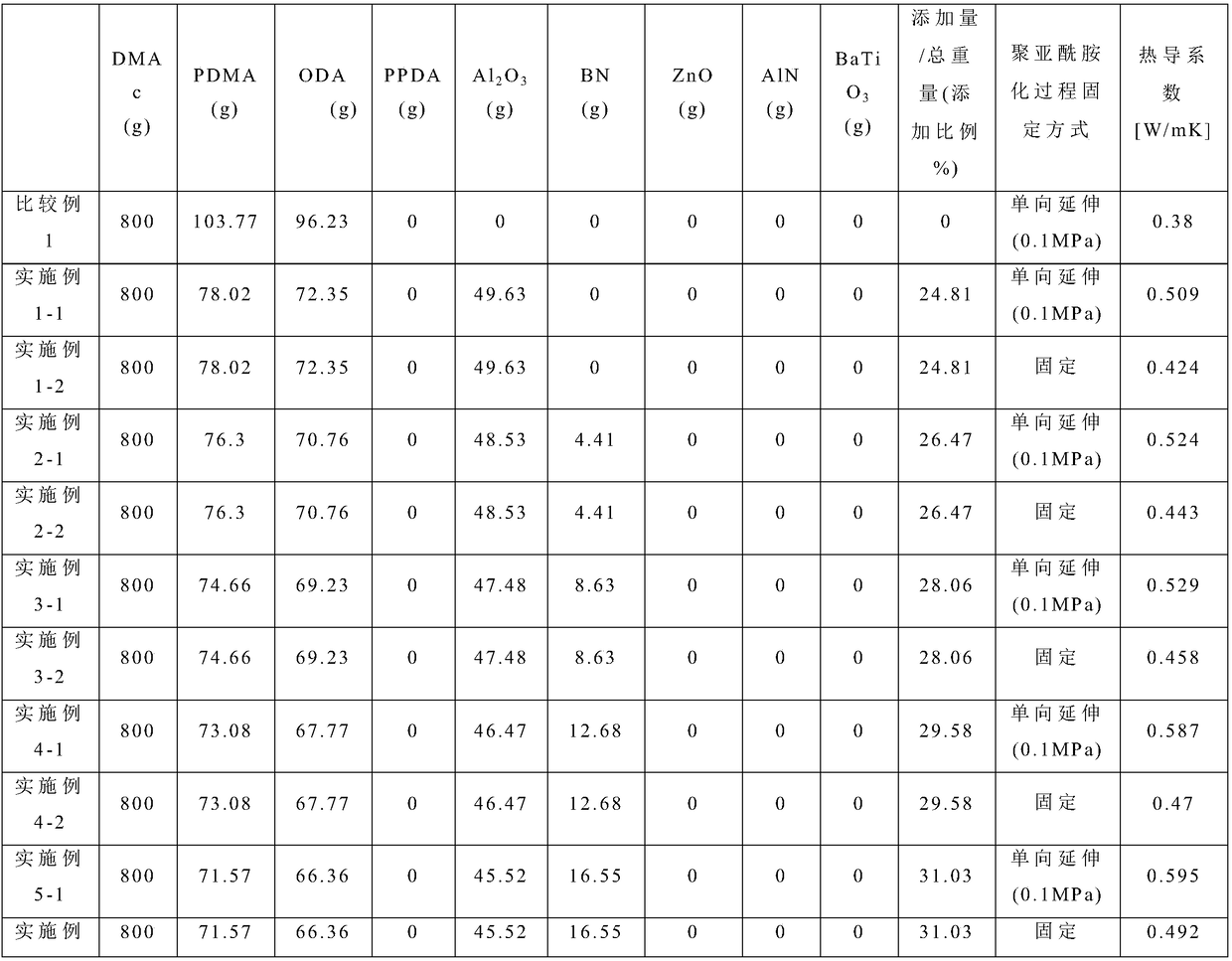

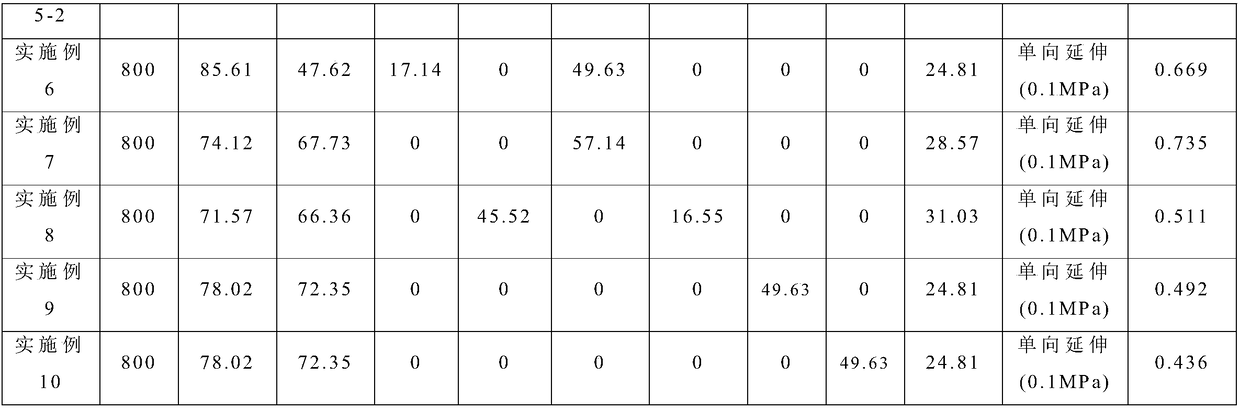

Embodiment 1-1

[0038] 49.63 g of alumina was added to 800 g of dimethylacetamide (DMAc) (purity: 99.95 wt %), and then, the dimethylacetamide solution was uniformly mixed to form a suspension.

[0039] Next, 72.35 g of 4,4'-diaminodiphenyl ether (ODA) was added to the suspension, and mixed evenly to dissolve it.

[0040] Next, 78.02 g of pyromellitic dianhydride (PDMA) was added and stirred for 6 hours to perform a polymerization reaction to obtain a polyamic acid mixture. The temperature of the polymerization reaction is controlled at 20°C to 30°C. The subsequent drying, film formation, imidization, and uniaxial stretching are the same as in Comparative Example 1, and will not be repeated here.

Embodiment 1-2

[0042] The steps of Example 1-2 are similar to those of Example 1-1. The difference between Example 1-2 and Example 1-1 is that the fixing method is different in the polyimidization process. In Example 1-2, the polyimide film In a fixed state, the polyamic acid film was heated at 300° C. for 10 minutes to perform an imidization reaction to obtain a polyimide film.

Embodiment 2-1

[0044] 48.53 g of alumina and 4.41 g of boron nitride were added to 800 g of dimethylacetamide (DMAc) (purity: 99.95 wt %), and then the dimethylacetamide solution was uniformly mixed to form a suspension.

[0045] Next, 70.76 g of 4,4'-diaminodiphenyl ether (ODA) was added to the suspension, and mixed evenly to dissolve it.

[0046] Next, 76.3 g of pyromellitic dianhydride (PDMA) was added, and stirred for 6 hours to perform a polymerization reaction to obtain a polyamic acid mixture. The temperature of the polymerization reaction is controlled at 20°C to 30°C. The subsequent drying, film formation, imidization, and uniaxial stretching are the same as in Comparative Example 1, and will not be repeated here.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thermal conductivity | aaaaa | aaaaa |

| Thermal conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com