Shellac waste residue culture medium for soilless cultivation and preparation method thereof

A culture medium and soilless cultivation technology, applied in the direction of culture medium, planting medium, botanical equipment and methods, etc., can solve the problems of waste of natural resources and achieve the effect of promoting the utilization of resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0031] The preparation method of shellac waste slag glue foam material culture substrate described in the embodiment of the present invention 1~9, concrete operation steps are as follows:

[0032](1) Weigh shellac waste residue glue, TGIC, composite blowing agent and polyethylene glycol according to the formula; raise the temperature of shellac waste residue glue to 60°C under electric stirring (it can also be heated to the range of 50~80°C Any temperature, such as 50°C, 80°C), stir for 15 minutes, add the measured TGIC and composite blowing agent, and then add the volumetric composite filler, continue to stir for 30 minutes and 10~30 minutes to make it evenly mixed.

[0033] (2) Pour the mixture into a round table-shaped molding mold that has been coated with release agent silicone oil, and then place it at 180 0 C (can also take 160~180 0 Any temperature within the range of ℃, such as 160 ℃, 180 ℃) heating and curing foaming in an oven for 30min 30~45min (can also take any ...

Embodiment 1

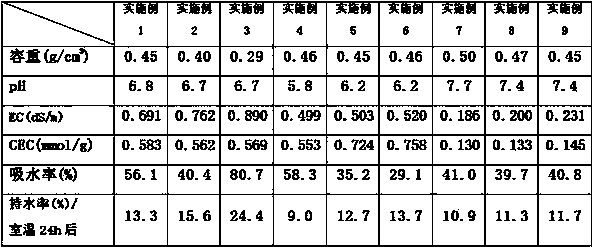

[0036] For the preparation methods of Examples 1-9, refer to the preparation method of Example 1, and see Table 1 for the proportions of raw materials by mass.

[0037] Table 1 The ratio of raw materials in parts by mass of shellac waste slag rubber foam material culture substrate (embodiments 1-9)

[0038]

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com