Preparation method of biodegradable polyester amide modified polylactic acid

A polyester amide and biodegradation technology, applied in the field of polylactic acid, can solve the problems of polylactic acid racemization, poor polylactic acid crystallinity, low melting point, etc., and achieve the effects of mild conditions, cheap raw materials, and easy availability of raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

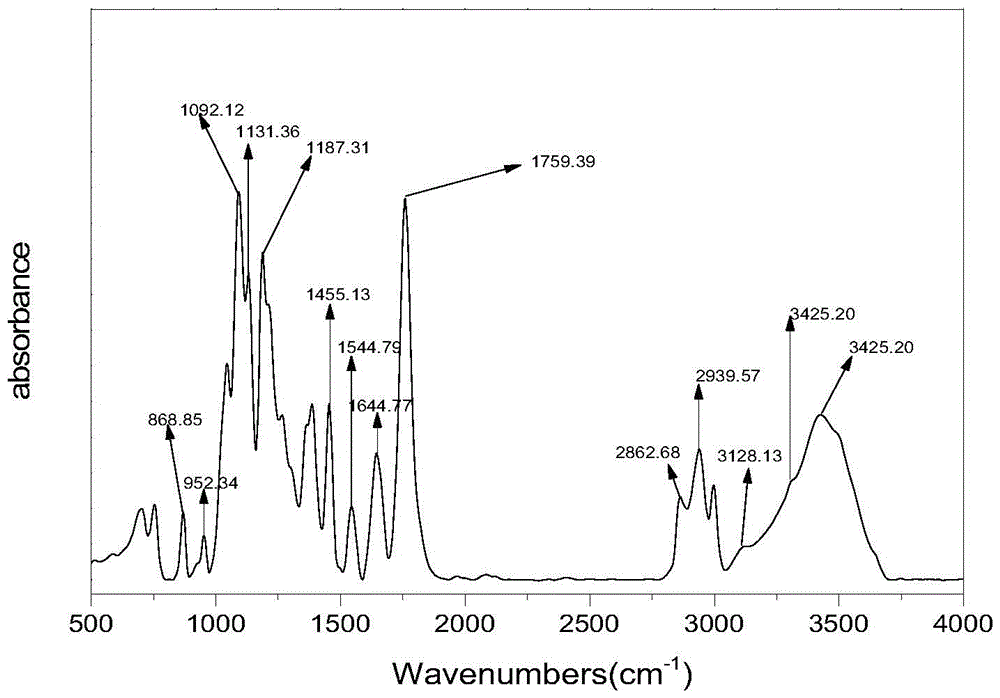

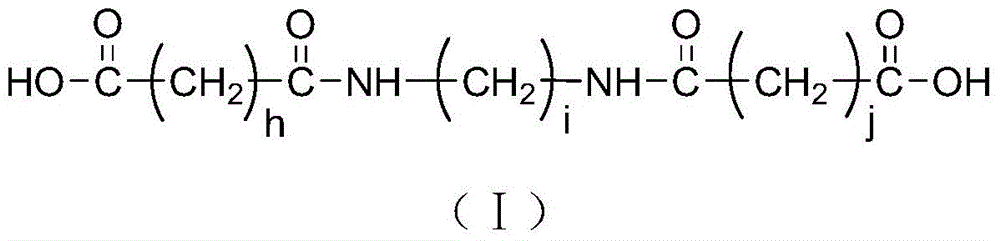

[0045] 1) Preparation of short polyamide diacid: Weigh 50.00 parts of nylon 610 salt, 31.77 parts of sebacic acid, and 0.20 parts of phosphorous acid in parts by weight, and react at 200°C under normal pressure for 1 hour under nitrogen protection, and then heat up to 210° C. and react under normal pressure for 3 hours to obtain a short polyamide diacid with an acid value of 202.86 mgKOH / g and a hydroxyl value of 1.14 mgKOH / g.

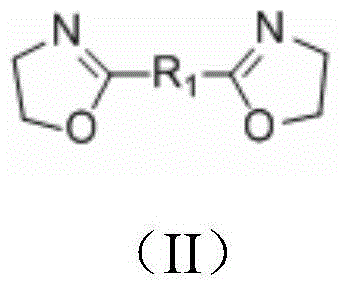

[0046] 2) Preparation of polyester amide prepolymer: Weigh 57.89 parts of short polyamide diacid prepared in step 1), 42.07 parts of polyethylene glycol (M=400g / mol), 0.20 parts of phosphorous acid, chlorine 0.10 parts of stannous chloride, 0.10 parts of p-toluenesulfonic acid, under the protection of nitrogen, the temperature was raised to 200 ° C under normal pressure for 1 hour, and then a decompression device was used, the temperature was raised to 210 ° C, and the reaction was gradually reduced by a water pump for 2 hours. Then use an oil pump to ...

Embodiment 2

[0051] 1) Preparation of polyester amide prepolymer: Weigh 57.89 parts of short polyamide diacid prepared in step 1) of Example 1), 42.07 parts of polyethylene glycol (M=600g / mol), phosphorous acid in parts by weight 0.20 parts, 0.10 parts of stannous chloride, 0.10 parts of p-toluenesulfonic acid, under the protection of nitrogen, the temperature was raised to 200 ° C under normal pressure for 1 hour, and then a decompression device was used, the temperature was raised to 210 ° C, and the water pump was used to depressurize gradually React for 2 hours, then depressurize with an oil pump, and react for 3 hours in a 3 mmHg decompression system to obtain a polyester amide prepolymer with an acid value of 35.02 mgKOH / g and a hydroxyl value of 20.034 mgKOH / g.

[0052] 2) Preparation of polylactic acid-b-polyesteramide: Weigh 20.00 parts of polylactic acid in Step 3) of Example 1, 13.22 parts of polyester amide prepolymer prepared in Step 1) of Example 2, and sub 0.20 parts of phos...

Embodiment 3

[0055] 1) Preparation of polyester amide prepolymer: Weigh 35.50 parts of short polyamide diacid prepared in step 1) of Example 1), 65.10 parts of polyethylene glycol (M=1000g / mol), phosphorous acid 0.20 parts, 0.10 parts of stannous chloride, 0.10 parts of p-toluenesulfonic acid, under the protection of nitrogen, the temperature was raised to 200 ° C under normal pressure for 1 hour, and then a decompression device was used, and the temperature was raised to 210 ° C. React for 2 hours, and then use an oil pump to reduce the pressure to 3 mmHg and react for 3 hours to obtain a polyester amide prepolymer with an acid value of 22.22 mgKOH / g and a hydroxyl value of 15.31 mgKOH / g.

[0056] 2) Preparation of polylactic acid-b-polyesteramide prepolymer: Weigh 20.00 parts of polylactic acid prepolymer in Step 3) of Example 1, and polyester amide prepolymer prepared in Step 1) of Example 3 in parts by weight. 17.12 parts of polymer, 0.20 parts of phosphorous acid, 0.10 parts of stanno...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hydroxyl value | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com