PLA/PBAT film capable of being rapidly degraded and preparation method thereof

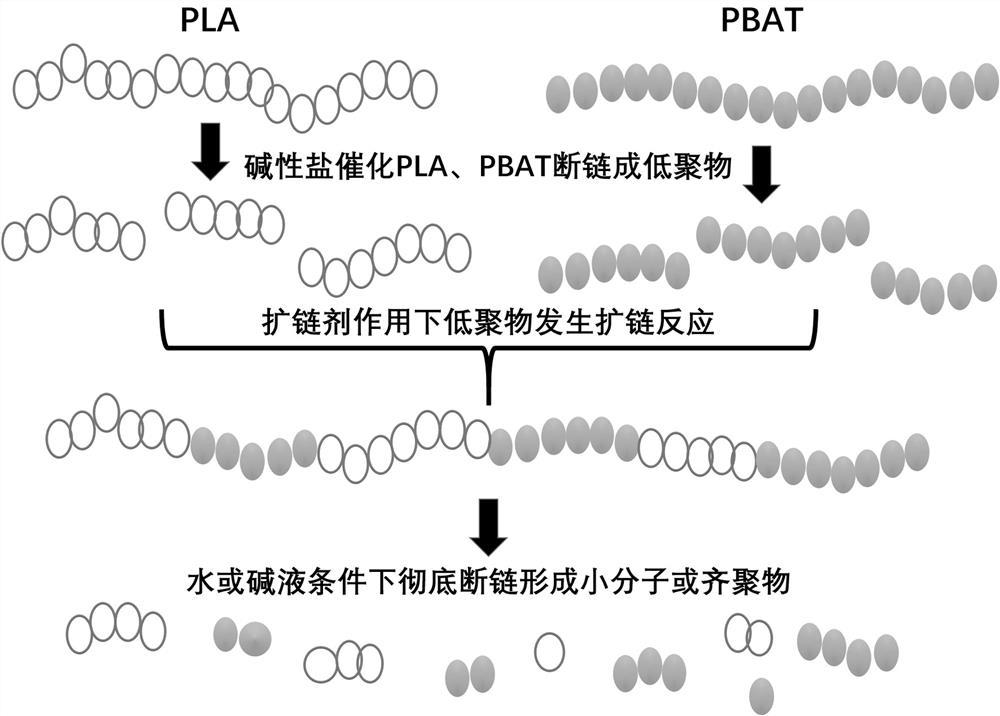

A rapid degradation and film technology, which is applied in the field of PLA/PBAT film and its preparation, can solve the problems of poor film compatibility, poor toughness, and long degradation cycle, etc., to achieve improved compatibility, low preparation cost, and improved ductility Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] Exemplary implementation methods of the present invention will be described in detail below. However, these implementation methods are for exemplary purposes only, and the present invention is not limited thereto. Any suitable melt processing technology can be used, such as banburying and single-screw extrusion blending, to obtain PLA / PBAT blended composite materials, and then through subsequent molding, such as: compression molding, injection molding, tape casting, All can achieve the purpose of toughening the product and improving its degradation rate.

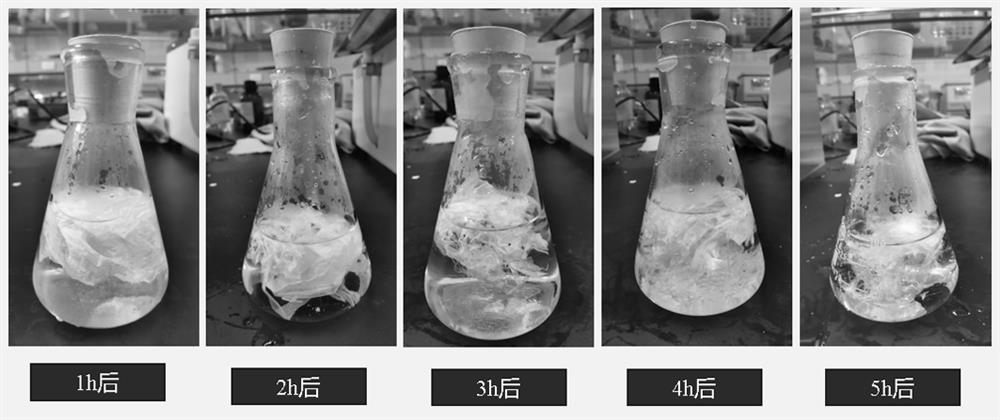

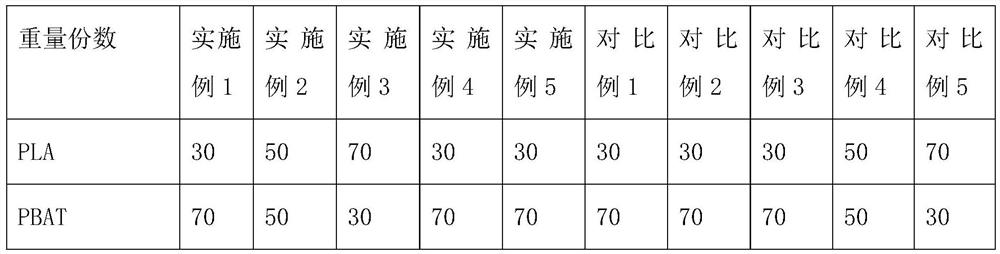

[0026] The present invention will be further described in detail with specific examples below. This example provides 5 kinds of PLA / PBAT film compositions and 5 sets of comparative examples. Carry out batching according to the embodiment shown in table 1 and the prescription of comparative example. PLA and PBAT were vacuum-dried in a vacuum oven at 80°C for 12 hours before batching. During extrusion granulation, ex...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com