Preparation method of aliphatic polyester amide with urea bond

A polyester amide and aliphatic diamine technology, applied in the field of polyester amide, can solve the problems of monomer volatilization loss, low polyester amide bond content, difficult control of feed ratio, etc., and achieve mild conditions, cheap and easy raw materials The effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

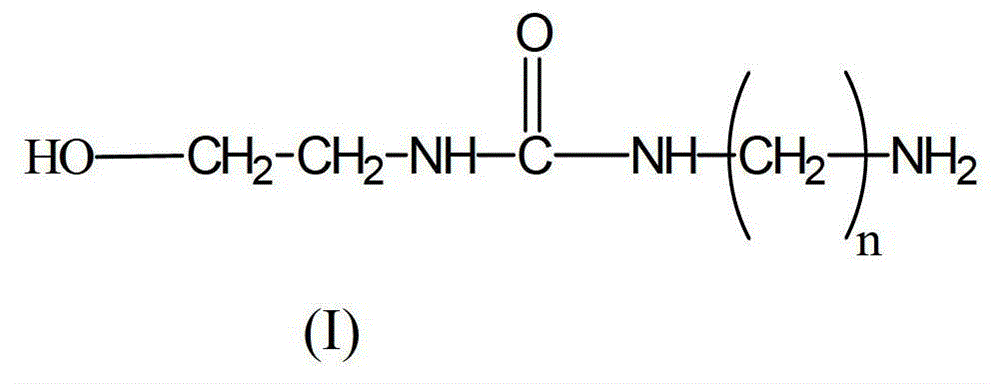

[0042] 1) Preparation of amino-terminated hydroxyurea monomer (HAU): Dissolve 39.6 parts of octanediamine in 50ml of N,N-dimethylformamide (DMF), raise the temperature to 160°C; weigh 60.4 parts by weight A portion of 2-oxazolidinone was dissolved in 50ml of DMF, and added dropwise to the above-mentioned octyldiamine solution; after the dropwise addition, the reaction was continued for 5 hours, cooled to room temperature, a white solid was precipitated, filtered under reduced pressure, and a white solid was obtained , the measured hydroxyl value is 487.05mgKOH / g, and its molecular weight is 230.36, which is consistent with the theoretical molecular weight of 231.

[0043] 2) Preparation of polyester amide prepolymer with urea bonds: 69.3 parts of HAU monomer prepared in step 1), 145.6 parts of sebacic acid, 27.1 parts of 1,4-butanediol were weighed in parts by weight, 0.48 parts of phosphorous acid, 0.24 parts of stannous chloride, under the protection of nitrogen, heat up to ...

Embodiment 2

[0046] 1) Preparation of polyester amide prepolymer with urea bonds: Weigh 11.6 parts of HAU monomer prepared in step 1) in Example 1, 141.6 parts of sebacic acid, 1,4-butanediol in parts by weight 58.6 parts, 0.42 parts of phosphorous acid, 0.21 parts of stannous chloride, under the protection of nitrogen, heat up to 160 ° C, slowly heat up to 200 ° C within 2 hours, and then switch to a decompression device, first use a water pump to gradually decompress the reaction After 2.5 hours, the oil pump was used to reduce the pressure to 3mmHg and react for 3 hours to obtain a PrePEAU prepolymer with an intrinsic viscosity of 0.26dL / g, an acid value of 39.19mgKOH / g, and a hydroxyl value of 32.01mgKOH / g.

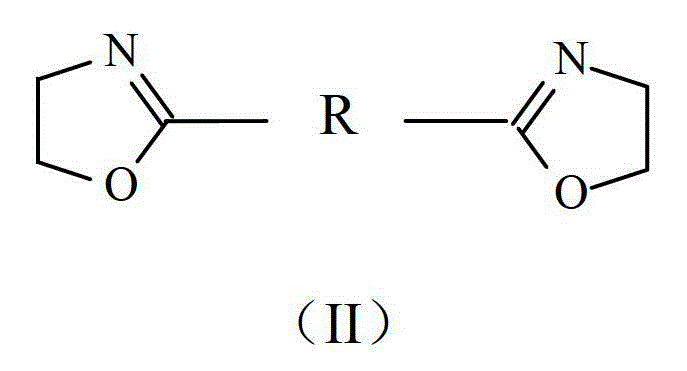

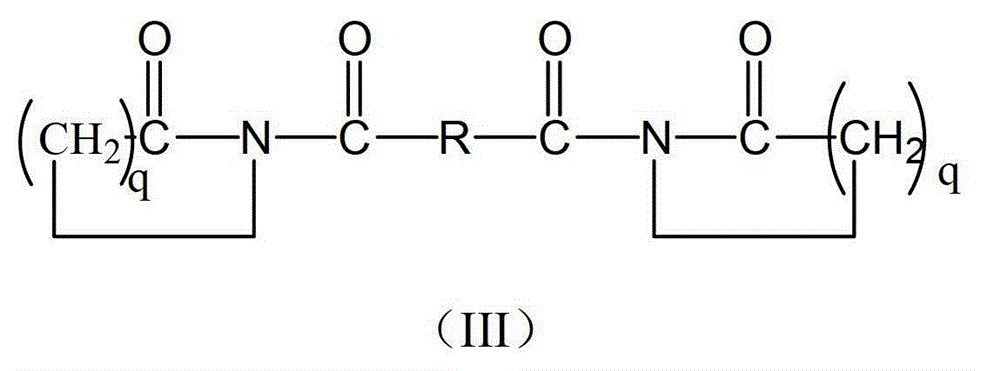

[0047] 3) Weigh 51.5 parts of PrePEAU prepolymer prepared in step 2), 3.9 parts of 1,4-phenyl-bis(2-oxazoline), 4.9 parts of adipyl biscaprolactam, catalyst chlorinated chlorinated 0.12 parts of tin and 0.003 parts of p-toluenesulfonic acid were reacted at 200°C under normal press...

Embodiment 3

[0049] 1) Preparation of polyester amide prepolymer with urea bonds: Weigh 23.1 parts of HAU monomer prepared in step 1) in Example 1, 131.5 parts of sebacic acid, 1,4-butanediol in parts by weight 49.5 parts, 0.41 parts of phosphorous acid, 0.20 parts of stannous chloride, under the protection of nitrogen, raise the temperature to 160°C, slowly raise the temperature to 200°C within 2 hours, then switch to a decompression device, and first use a water pump to gradually depressurize the reaction After 2.5 hours, the oil pump was used to reduce the pressure to 3 mmHg and react for 3 hours to obtain a PrePEAU prepolymer with an intrinsic viscosity of 0.29 dL / g, an acid value of 31.13 mgKOH / g, and a hydroxyl value of 45.76 mgKOH / g.

[0050] 2) Weigh 50.9 parts of PrePEAU prepolymer prepared in step 1), 3.1 parts of 1,4-phenyl-bis(2-oxazoline), 6.9 parts of adipyl biscaprolactam, and chlorinate the catalyst 0.12 parts of stannous and 0.003 parts of p-toluenesulfonic acid were react...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hydroxyl value | aaaaa | aaaaa |

| hydroxyl value | aaaaa | aaaaa |

| hydroxyl value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com