Machining device for milling cutters

A processing device and milling cutter technology, applied in the field of milling machine parts processing, can solve problems such as reducing work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The following is further described in detail by specific embodiments:

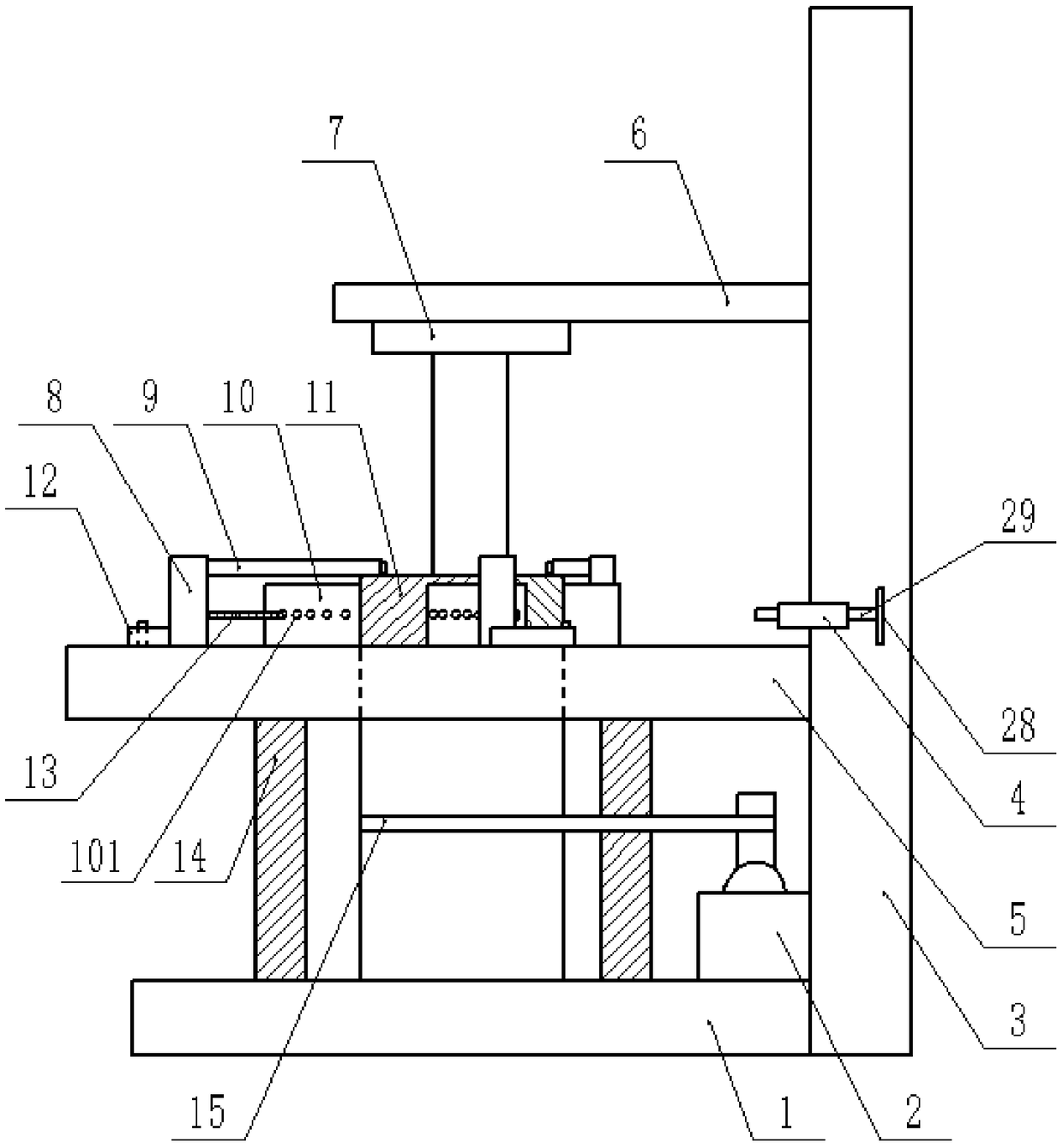

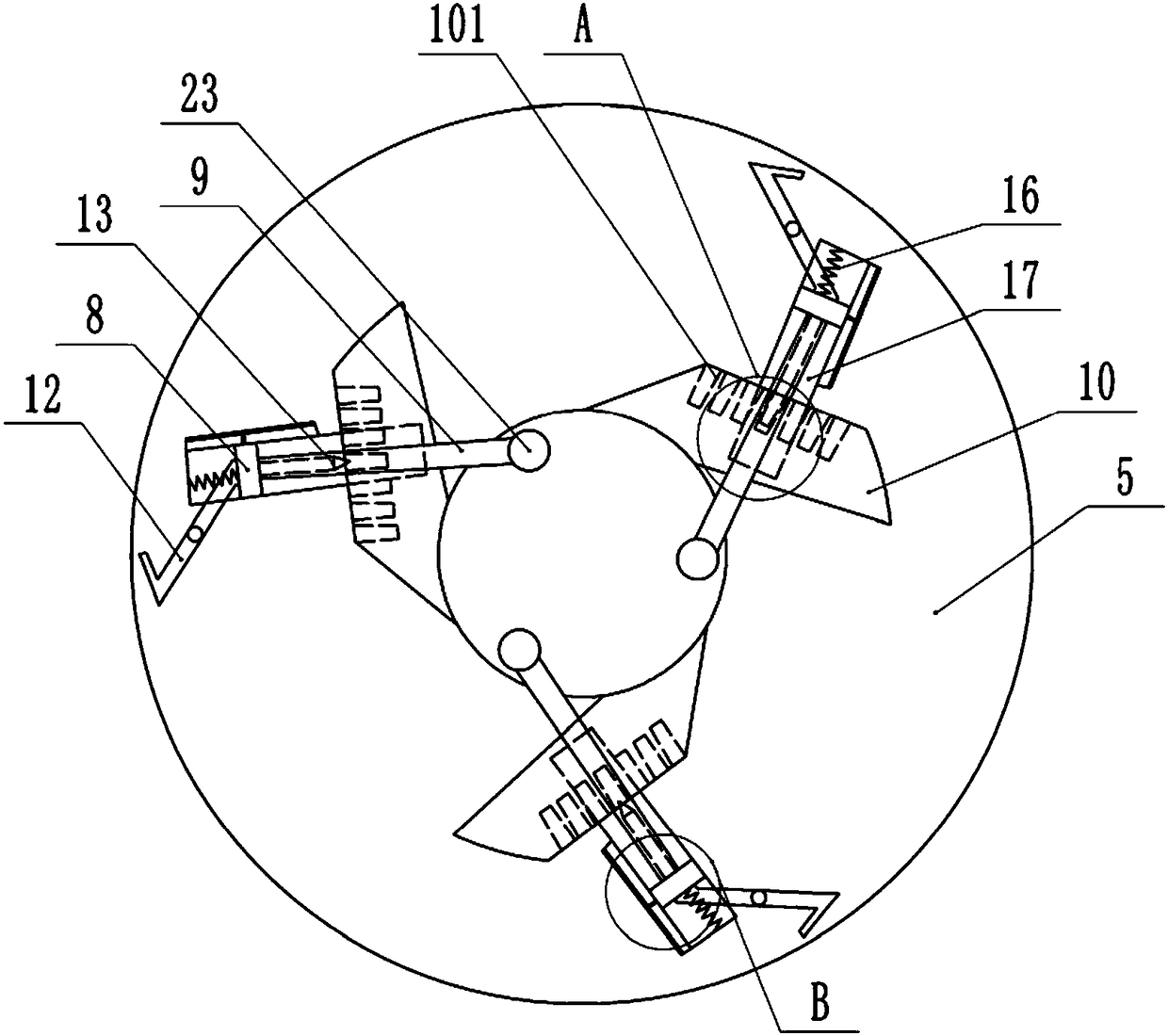

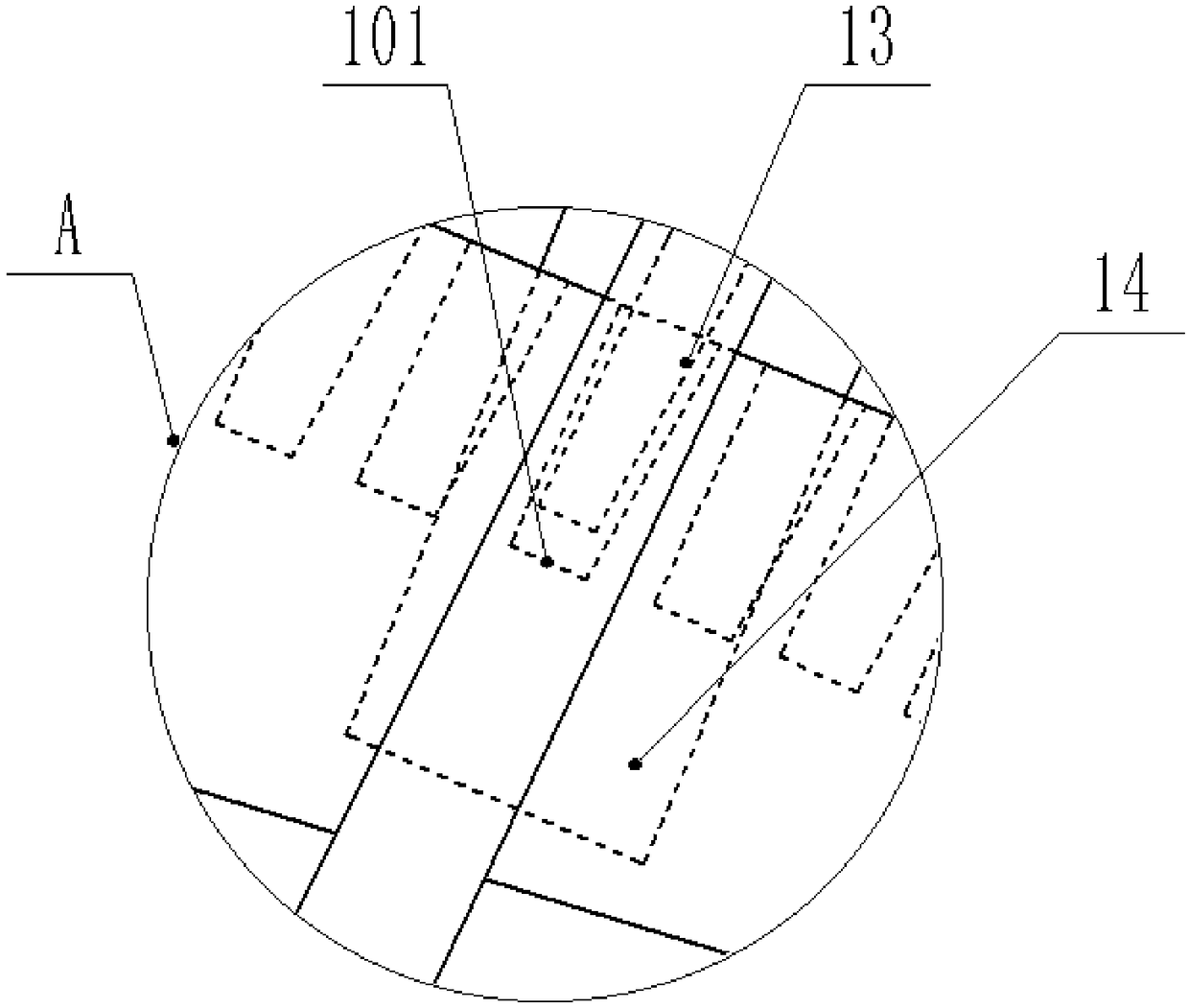

[0017] The reference signs in the accompanying drawings include: base 1, motor 2, slide rail 3, fixed tube 4, rotating plate 5, transverse plate 6, chuck 7, baffle 8, grinding rod 9, blade 10, top tightening hole 101. Grinding wheel 11, toggle rod 12, jacking rod 13, support rod 14, belt 15, spring 16, groove 17, grinding ball 23, scale 26, pointer 27, adjusting disc 28, pressing rod 29.

[0018] The example is basically as attached Figure 1-Figure 4 Shown: a milling cutter processing device, comprising a base 1 and a vertical slide rail 3, the bottom end of the slide rail 3 is welded on the base 1, the base 1 is provided with two vertical support rods 14, the support rod 14 A rotating disc 5 is slidably connected to the top of the rotating disc 5, a perforation is provided in the middle of the rotating disc 5, a grinding wheel 11 is rotatably connected in the perforation, a motor 2 is provided on...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com