Stable electroplate liquid

A technology of electroplating solution and stability, which is applied in the field of stable electroplating solution, can solve the problems of weak plating ability, poor stability of electroplating solution, and slow plating speed, and achieve fast plating speed, strong throwing ability and reduced surface tension Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0015] A kind of stable electroplating solution of the present invention, described comprises copper sulfate pentahydrate, sulfuric acid, hydrochloric acid, accelerator and wetting agent, and described accelerator is the mixture of one or more mercaptan compounds, described The wetting agent is a mixture of one or more polyalcohol compounds; the concentration of copper sulfate pentahydrate in the stable electroplating solution is 70g / L, the concentration of sulfuric acid is 96mL / L, and the concentration of hydrochloric acid is 44mg / L L, the concentration of the accelerator is 0.5mL / L, and the concentration of the wetting agent is 13mL / L. A preferred composition of the accelerator includes methyl mercaptan, ethanethiol, ethanedithiol, 1-propanethiol and 1,3-propanedithiol; the content percentage of the accelerator composition is: Thiol 40%, Ethanethiol 30%, Ethanedithiol 10%, 1-Propanedithiol 10%, and 1,3-Propanedithiol 5%. A preferred composition of the wetting agent includes...

Embodiment 2

[0017] A kind of stable electroplating solution of the present invention, described comprises copper sulfate pentahydrate, sulfuric acid, hydrochloric acid, accelerator and wetting agent, and described accelerator is the mixture of one or more mercaptan compounds, described The wetting agent is a mixture of one or more polyalcohol compounds; the concentration of copper sulfate pentahydrate in the stable electroplating solution is 77g / L, the concentration of sulfuric acid is 100mL / L, and the concentration of hydrochloric acid is 50mg / L L, the concentration of the accelerator is 0.7mL / L, and the concentration of the wetting agent is 16mL / L. A preferred composition of the accelerator includes methyl mercaptan, ethanethiol, ethanedithiol, 1-propanethiol and 1,3-propanedithiol; the content percentage of the accelerator composition is: Mercaptan 45%, Ethanethiol 35%, Ethanedithiol 15%, 1-Propanedithiol 15%, and 1,3-Propanedithiol 8%. A preferred composition of the wetting agent inc...

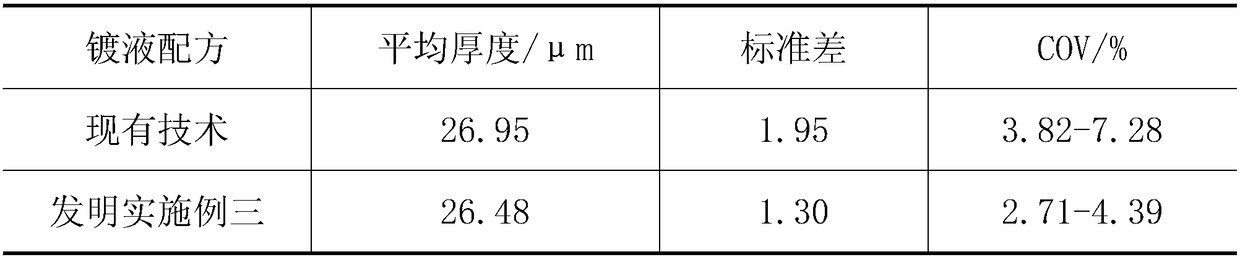

Embodiment 3

[0019] A kind of stable electroplating solution of the present invention, described comprises copper sulfate pentahydrate, sulfuric acid, hydrochloric acid, accelerator and wetting agent, and described accelerator is the mixture of one or more mercaptan compounds, described The wetting agent is a mixture of one or more polyalcohol compounds; the concentration of copper sulfate pentahydrate in the stable electroplating solution is 85g / L, the concentration of sulfuric acid is 108mL / L, and the concentration of hydrochloric acid is 65mg / L L, the concentration of the accelerator is 0.9mL / L, and the concentration of the wetting agent is 20mL / L. A preferred composition of the accelerator includes methyl mercaptan, ethanethiol, ethanedithiol, 1-propanethiol and 1,3-propanedithiol; the content percentage of the accelerator composition is: Thiol 50%, Ethanethiol 0%, Ethanedithiol 20%, 1-Propanedithiol 20%, and 1,3-Propanedithiol 10%. A preferred composition of the wetting agent include...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com