Installation method of overlength thin-wall flow guiding wall templates

An installation method and wall technology, which are applied in the direction of formwork/formwork/work frame, connection parts of formwork/formwork/work frame, and on-site preparation of building components, which can solve the problem of difficult safety and construction of the support formwork system. The problems of long cycle and one-time input of many materials have achieved the effect of shortening the cycle cycle of the wall, fast construction, and saving construction labor costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

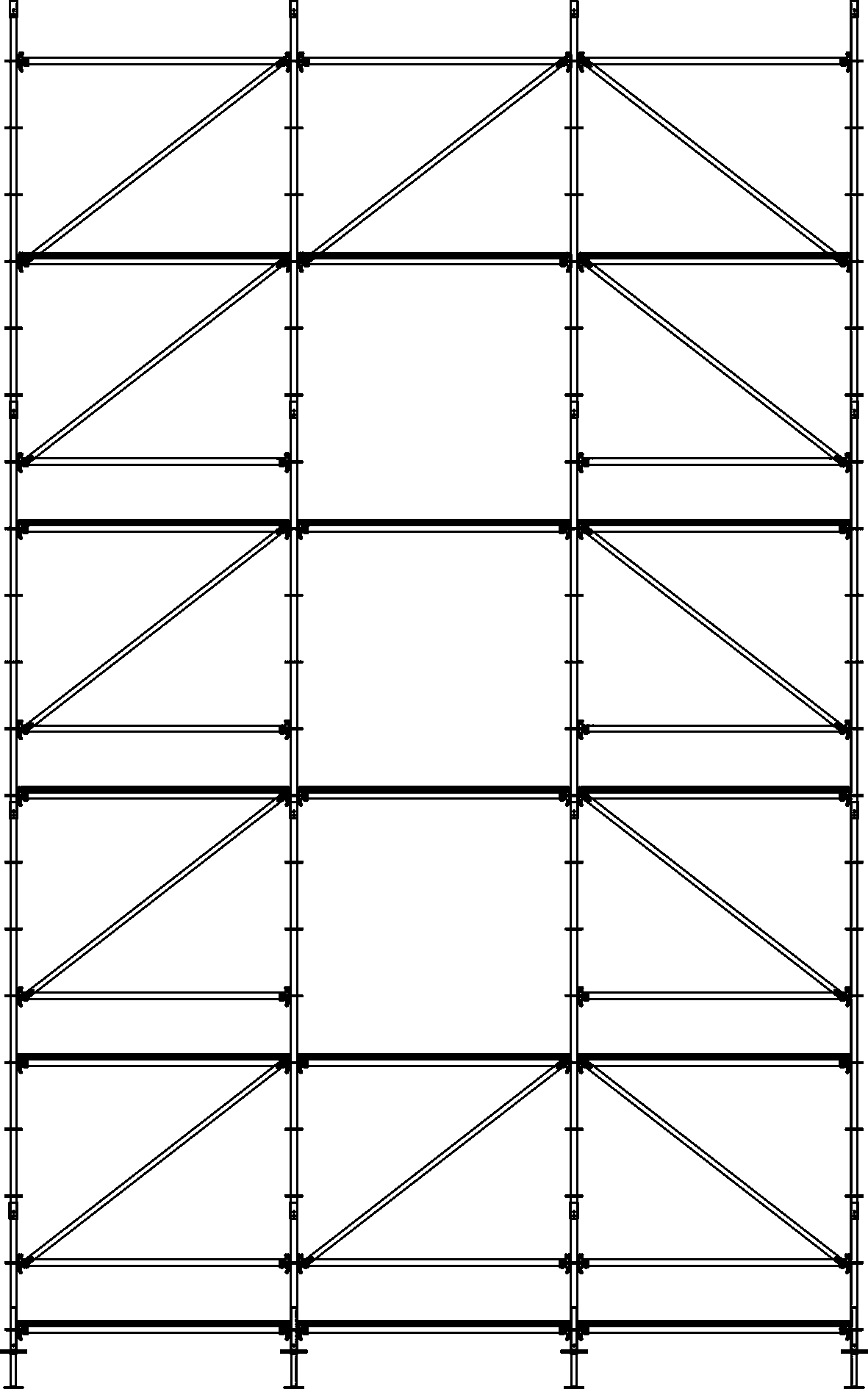

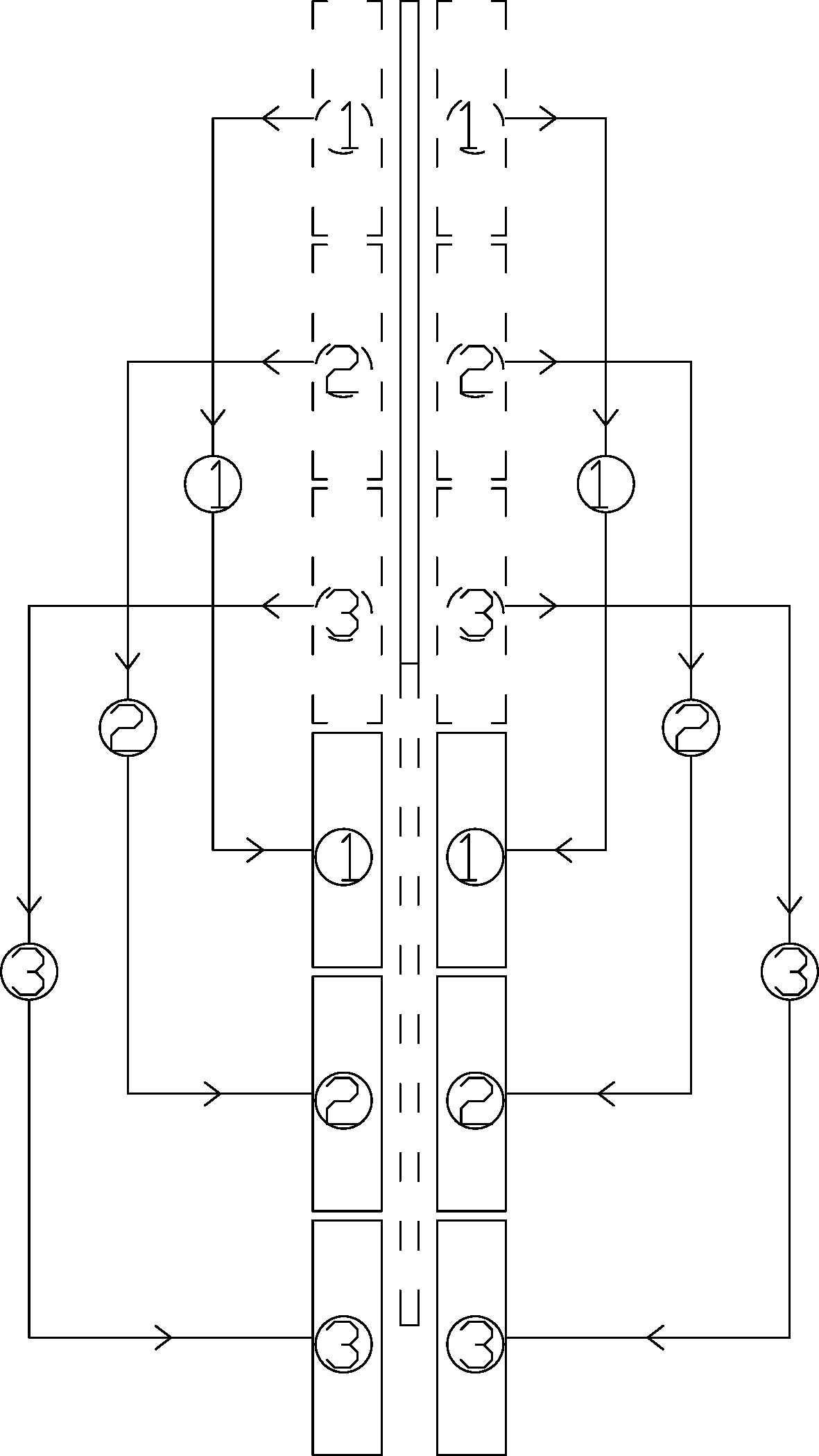

[0046] Such as figure 1 Among them, an ultra-long thin-wall diversion wall formwork installation method includes the following steps:

[0047] 1) Process the template according to the design standard;

[0048] 2) After the pre-cast wall concrete is chiseled, the base plate is poured, and then the wall reinforcement and formwork are installed using the mobile scaffolding platform;

[0049] 3) Concrete wall pouring in concrete formwork;

[0050] 4) After the pouring is completed, the formwork shall be removed after the concrete strength reaches the final strength.

[0051] In a preferred solution, in the step 2), after the bottom slab is poured, the horizontal construction joint treatment, the wall reinforcement installation, the wall end formwork installation and the wall side formwork installation are sequentially performed.

Embodiment 2

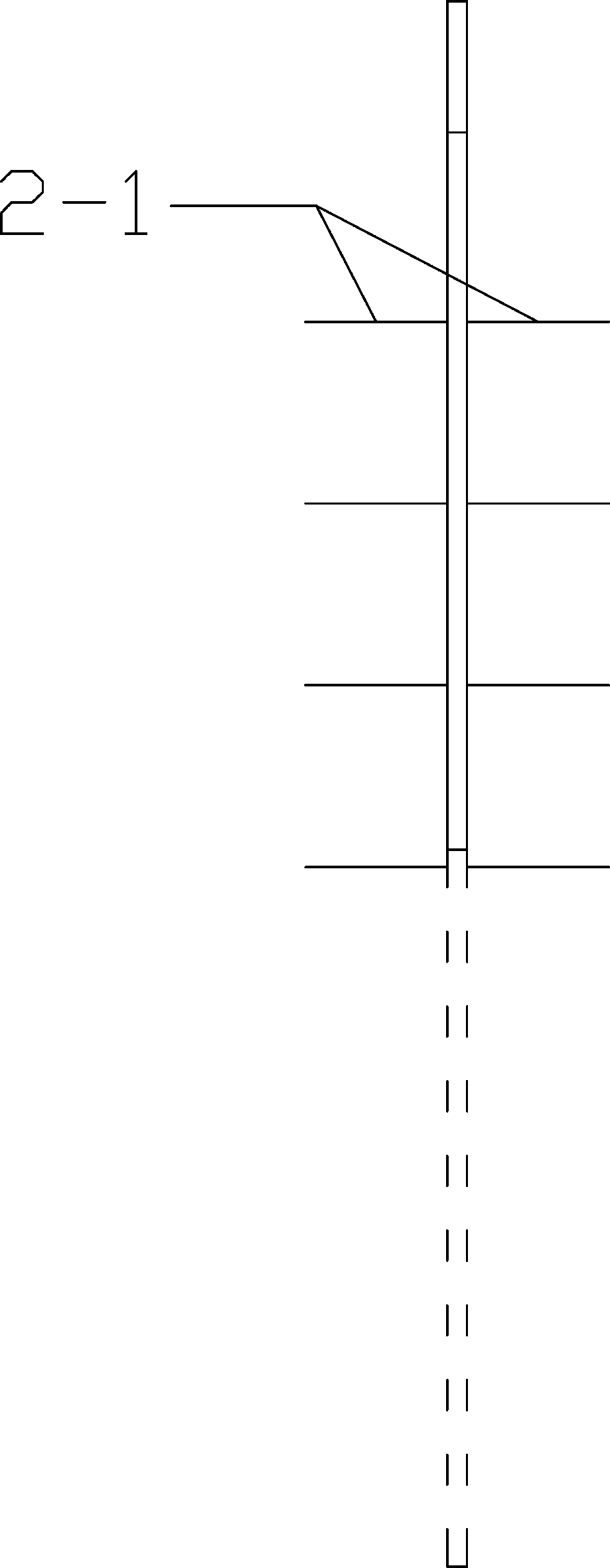

[0053] On the basis of Embodiment 1, the operation of treating the transverse construction joints specifically includes: performing roughening treatment on the construction joints of the poured concrete wall.

Embodiment 3

[0055] On the basis of Embodiment 1, the installation of the wall reinforcement is as follows: the wall reinforcement is bound to the top at one time according to the design, and the wall reinforcement is installed according to the design.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com