Magnetic control collision bumper

A buffer and magnetic control technology, which is applied in the direction of shock absorbers, shock absorbers, liquid shock absorbers, etc., to achieve the effects of optimizing buffer characteristics, improving operational reliability, and improving performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] In order to make the purpose, technical solutions and advantages of the present invention clearer, detailed embodiments are provided, and the present invention will be described in further detail below in conjunction with the accompanying drawings:

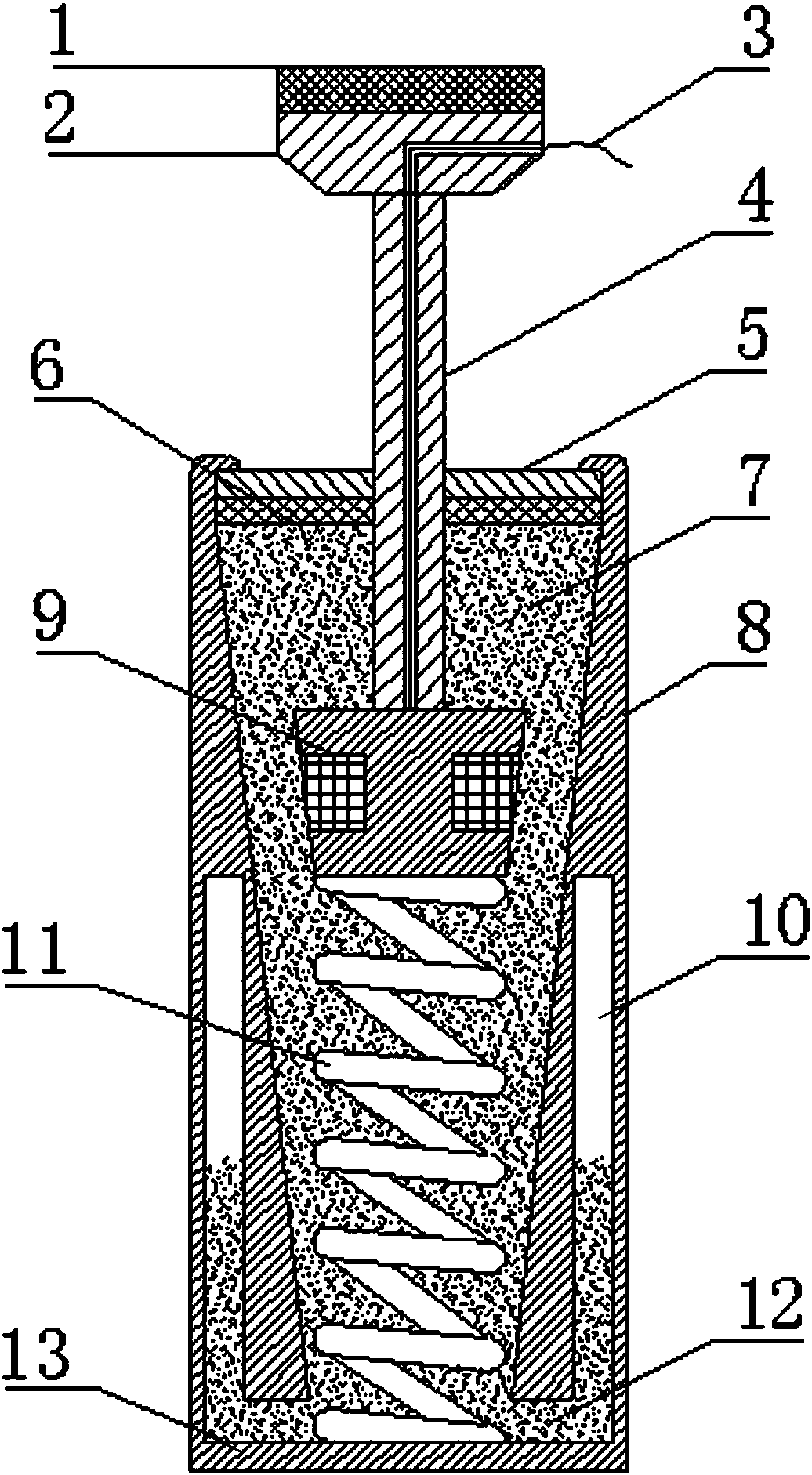

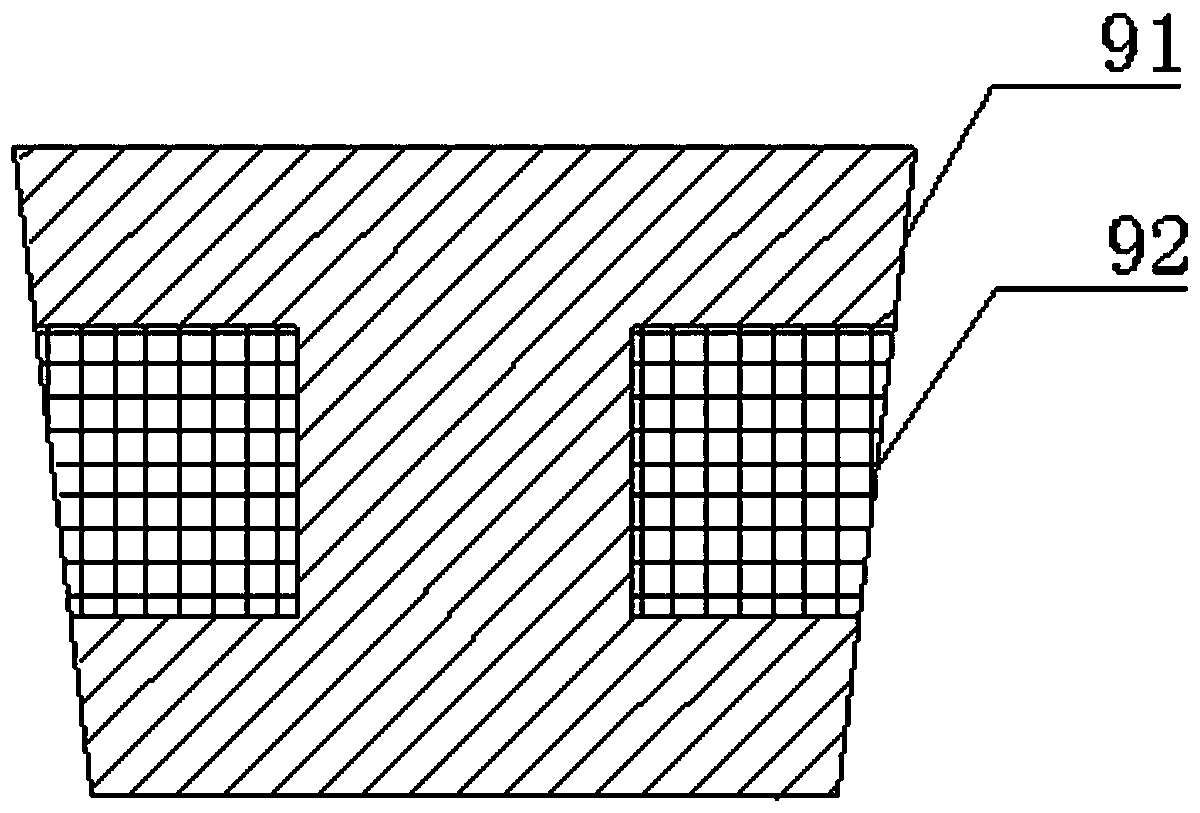

[0021] see figure 1 and figure 2 , this embodiment discloses a magnetically controlled collision buffer, including a working cylinder 8 and end covers 5 and bottom covers 13 located at both ends of the working cylinder 8 in the axial direction. The inner cavity of 8 is set to be large at the top and small at the bottom, so that the wall thickness of the cylinder wall of the working cylinder 8 gradually becomes thicker from top to bottom. The inner cavity of the working cylinder 8 is provided with a piston 9 and a spring 11, one end of the spring 11 is fixedly connected to the bottom of the piston 9, and the other end of the spring 11 is fixedly connected to the bottom cover 13 at the bottom of the working cylinder 8, so ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com