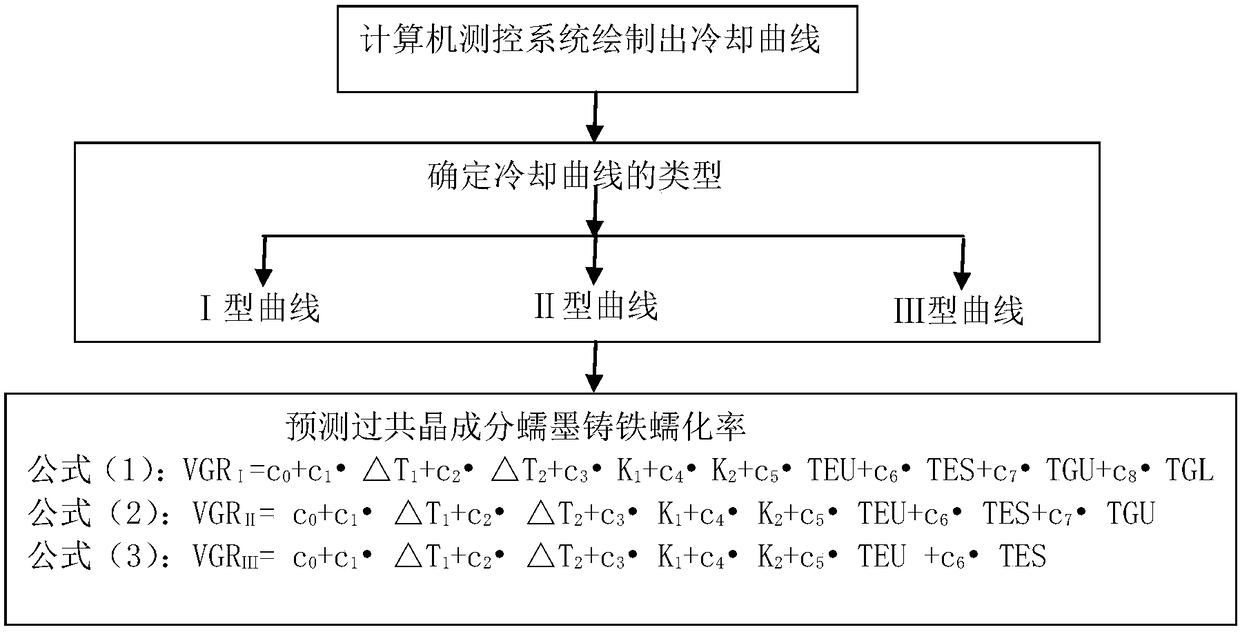

Method for predicting vermicularity of hypereutectic vermicular graphite cast iron

A technology of vermicular graphite cast iron and hypereutectic, which is applied in the field of predicting the creep rate of vermicular graphite cast iron with hypereutectic composition, and can solve problems such as the inability to predict the creep rate of vermicular graphite cast iron with hypereutectic composition

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0054] The hypereutectic vermicular graphite cast iron glass mold casting is prepared, and the vermicular rate of the product is required to be greater than 80%.

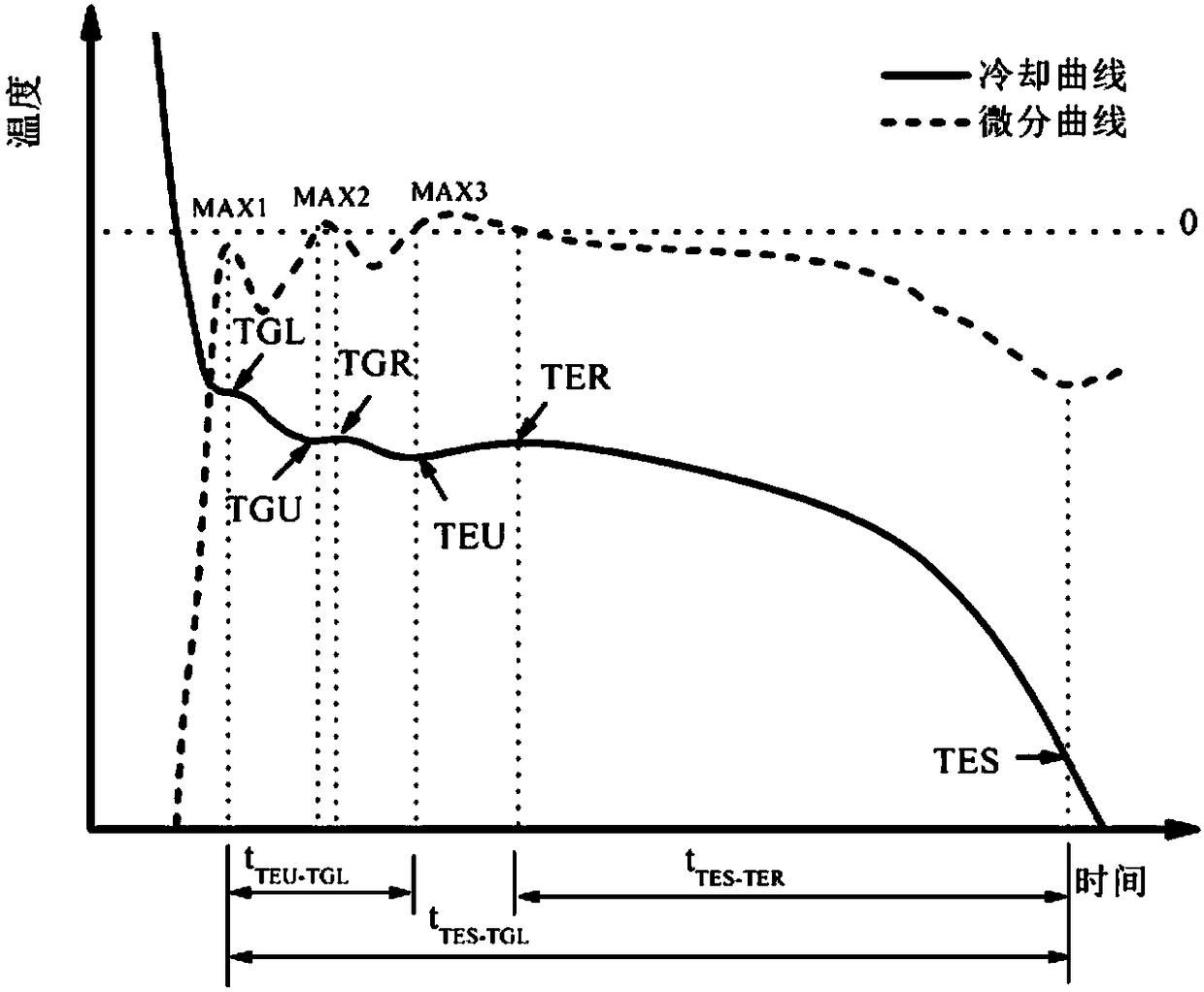

[0055] The first step is to record the change of temperature of the hypereutectic vermicular graphite cast iron molten iron with time through the computer measurement and control system and draw the cooling curve:

[0056] Get the vermicular graphite cast iron molten iron that has been processed through vermicularization and inoculation and pour it into a disclosed furnace front thermal analysis temperature collection sample cup of CN206002472U. A K-type thermocouple arranged in the center of the sample cup tests the vermicular graphite cast iron molten iron in the sample cup The temperature signal during the sample solidification process is converted into an electromotive force signal, and the electromotive force signal is transmitted to a computer measurement and control system RT-2009 vermicular graphite cast iron...

Embodiment 2

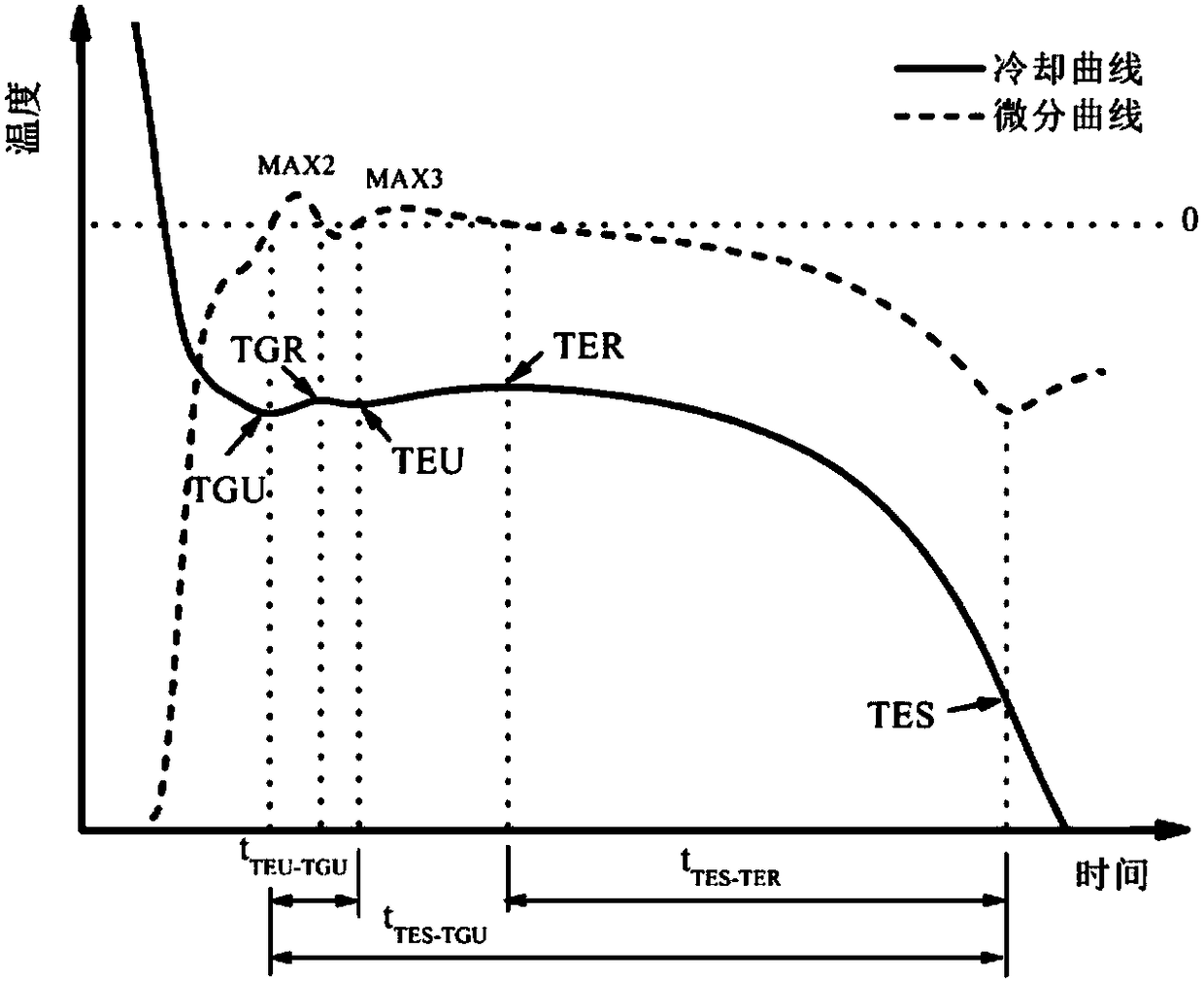

[0067] A hypereutectic vermicular graphite cast iron piston ring is prepared, and the product requires a vermicular rate greater than 80%.

[0068] The first step is to record the change of temperature of the hypereutectic vermicular graphite cast iron molten iron with time through the computer measurement and control system and draw the cooling curve:

[0069] Get the vermicular graphite cast iron molten iron that has been processed through vermicularization and inoculation and pour it into a disclosed furnace front thermal analysis temperature collection sample cup of CN206002472U. A K-type thermocouple arranged in the center of the sample cup tests the vermicular graphite cast iron molten iron in the sample cup The temperature signal during the sample solidification process is converted into an electromotive force signal, and the electromotive force signal is transmitted to a computer measurement and control system RT-2009 vermicular graphite cast iron intelligent online mea...

Embodiment 3

[0080] The hypereutectic vermicular graphite cast iron glass mold casting is prepared, and the vermicular rate of the product is required to be greater than 80%.

[0081] The first step is to record the change of temperature of the hypereutectic vermicular graphite cast iron molten iron with time through the computer measurement and control system and draw the cooling curve:

[0082] Get the vermicular graphite cast iron molten iron that has been processed through vermicularization and inoculation and pour it into a disclosed furnace front thermal analysis temperature collection sample cup of CN206002472U. A K-type thermocouple arranged in the center of the sample cup tests the vermicular graphite cast iron molten iron in the sample cup The temperature signal during the sample solidification process is converted into an electromotive force signal, and the electromotive force signal is transmitted to a computer measurement and control system RT-2009 vermicular graphite cast iron...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com