Aircraft engine shaft component supporting stiffness simulator

An aero-engine, stiffness simulation technology, applied in instruments, special data processing applications, electrical digital data processing, etc., can solve the problem of not having a rotor fulcrum, achieve good promotion significance, reduce radial stiffness, and eliminate test errors.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The specific embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

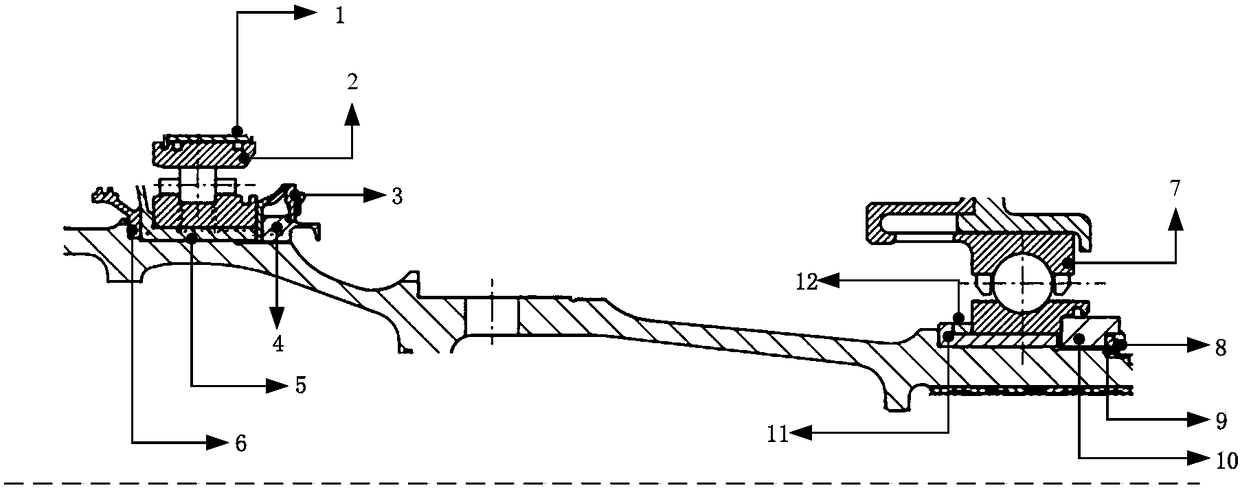

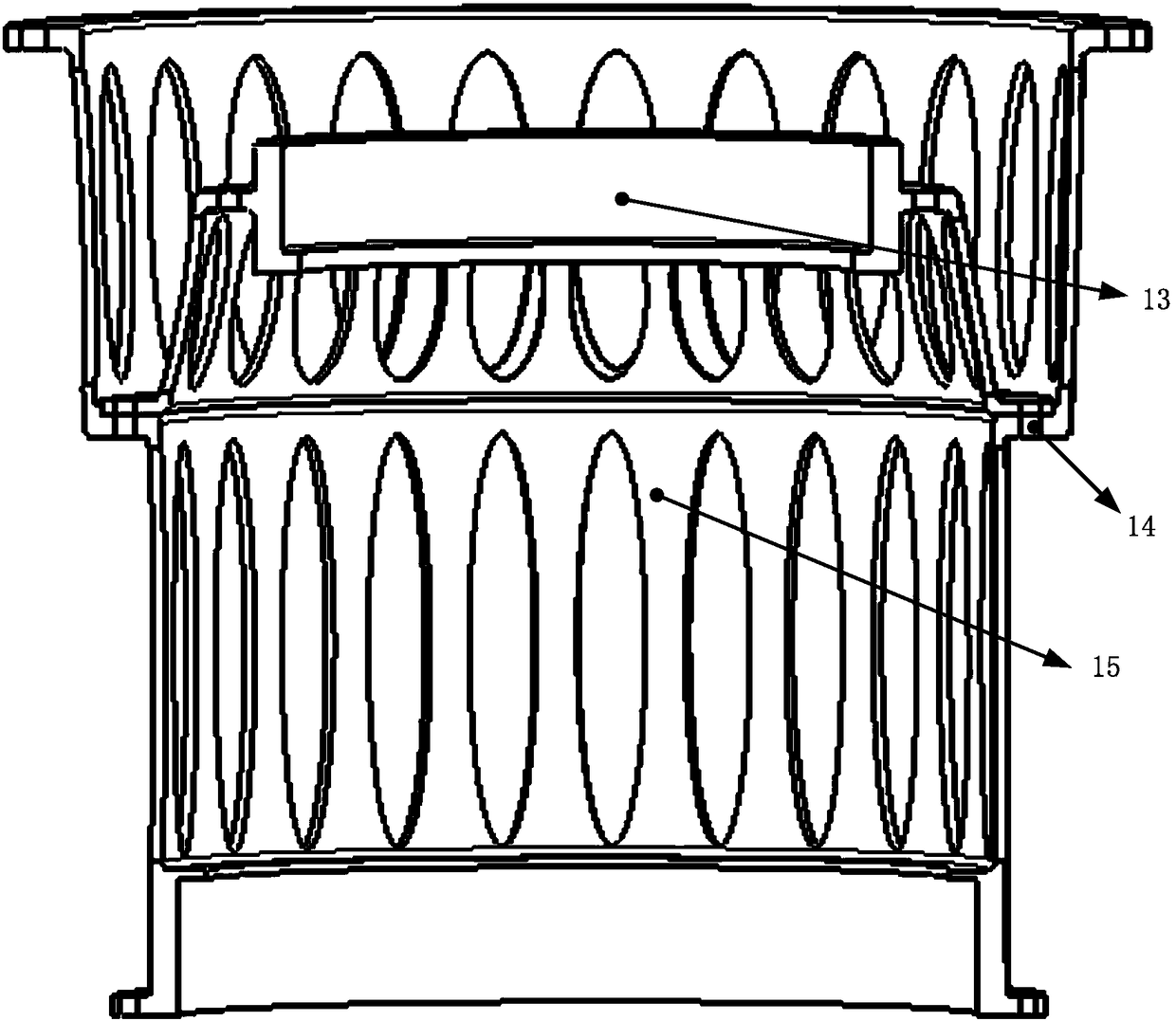

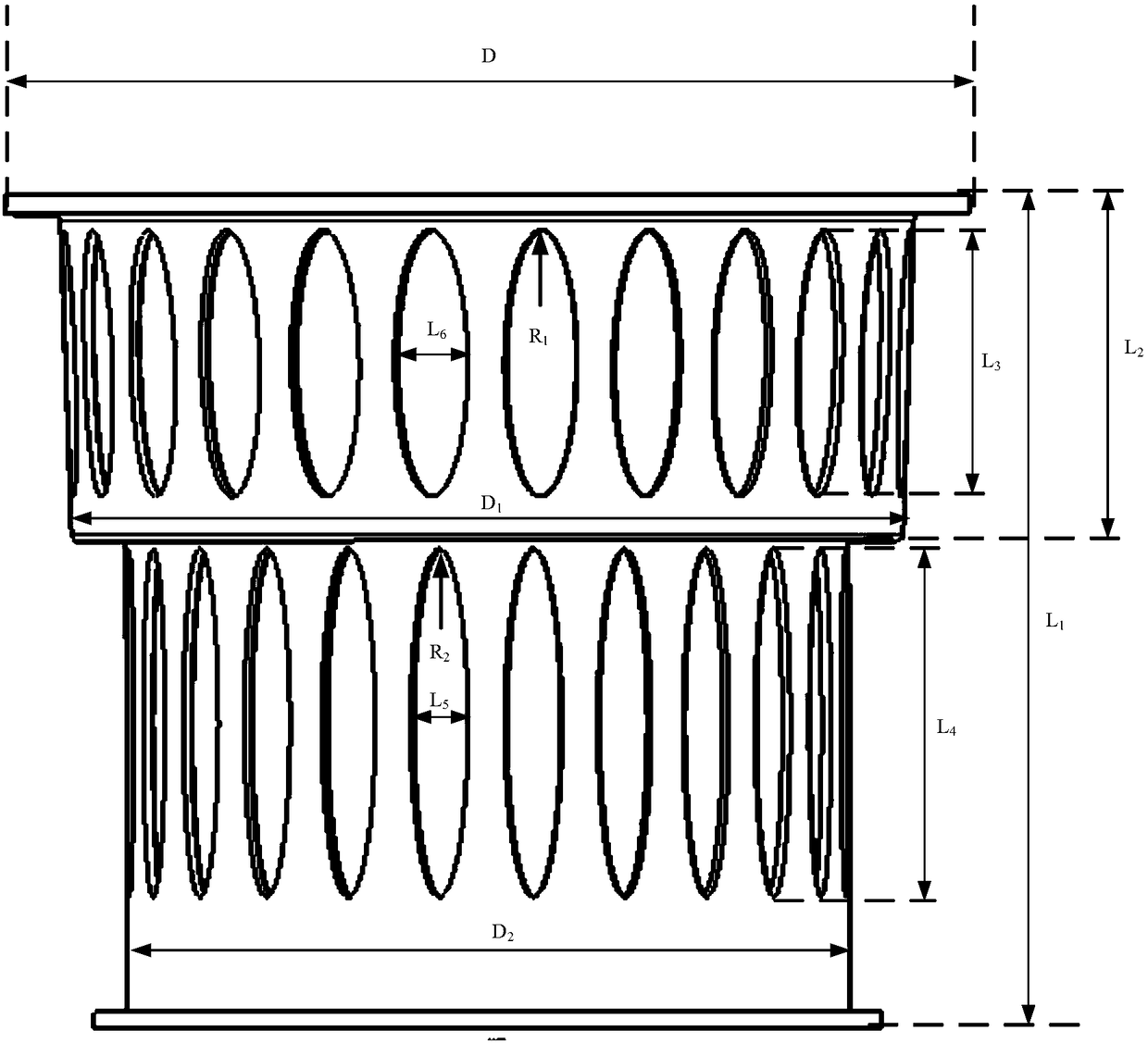

[0022] Taking the fan shaft of a turbofan engine with a large bypass ratio as an example, figure 1 It is a schematic diagram of fan shaft, bearing and related accessories, including inner steel sleeve 1, roller bearing 2, cup washer 3, nut 4, sealing grate A 5, sealing grate B 6, deep groove ball bearing 7 , Spring collar 8, stop piece 9, nut 10, bushing 11, adjusting pad 12. The "birdcage" stiffness simulator supports the test piece during the test and mainly bears the bending moment and axial load. The axial load is borne by the upper stiffness simulator through the deep groove ball bearing; the test piece undergoes swing deformation under the action of bending moment, and the upper and lower stiffness simulators are subjected to forces in opposite directions to form a force couple to balance the load borne by the test piece.

[0023] Ro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com