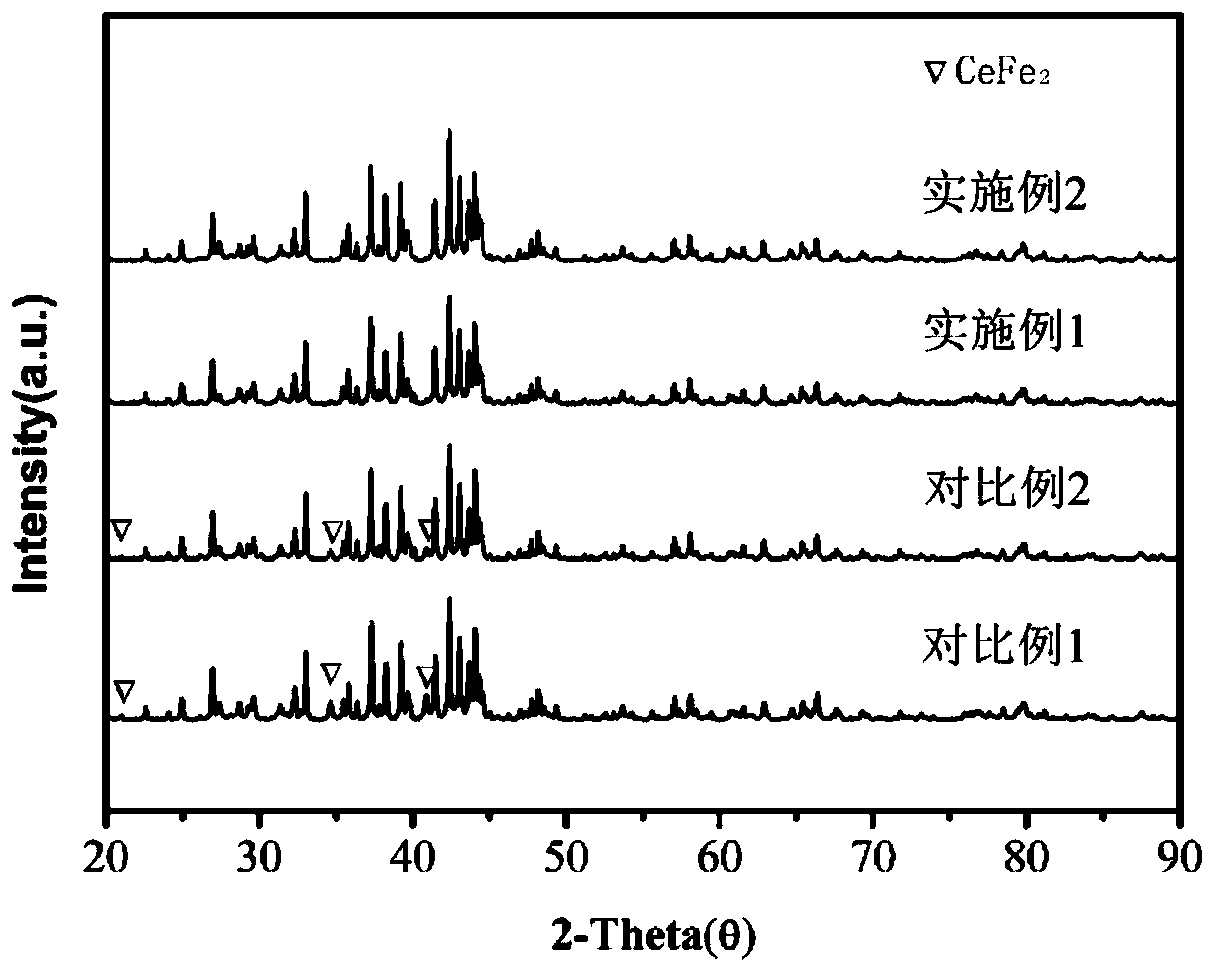

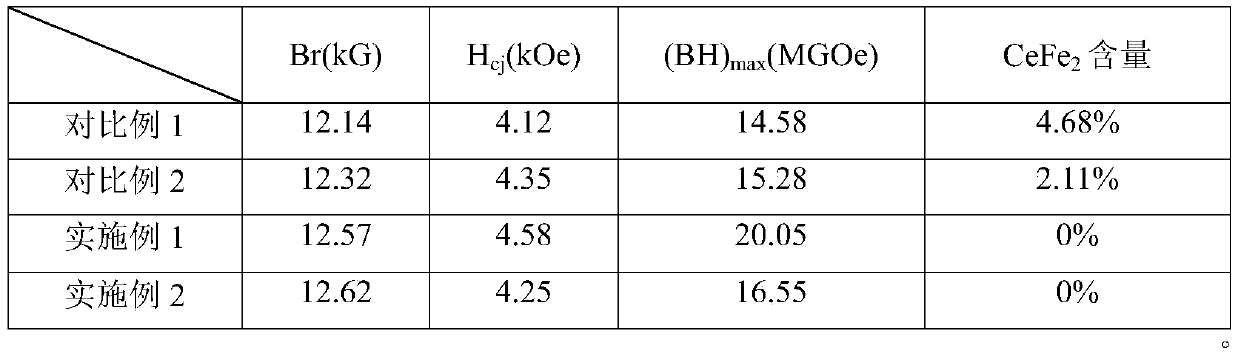

an inhibitor of cefe 2 Phase mixed rare earth iron boron magnet preparation method

A technology of mixing rare earths and magnets, which is applied in the fields of magnetic objects, magnetic materials, inductors/transformers/magnets, etc., which can solve problems such as restricting the development of mixed rare earth iron-boron, failing to meet the use requirements, reducing the magnetization intensity of magnets, etc., to improve performance , reduce production costs, optimize the effect of phase structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] 1) Melting ingots and quick-setting tablets: according to the nominal composition La 7 MM 24.5 Fe 66 M(Al 0.3 Cu 0.3 co 0.2 Ga 0.4 Zr 0.3 )B 1 (wt.%), select metal lanthanum and mixed rare earth MM (MM composition is Ce: 50%, La: 30%, Pr: 4%, Nd: 16%), iron, iron boron and other metals are placed in the crucible and It is filled with argon for smelting, and then poured onto a copper roller with a rotating speed of 3m / s to prepare a quick-setting thin strip with a thickness of 0.2-0.5mm.

[0033] 2) Hydrogen explosion, using a vacuum rotary hydrogen crushing furnace to carry out hydrogen explosion treatment on the quick-setting thin strips to obtain particles of uniform size.

[0034] 3) Jet milling, orientation pressing and isostatic pressing: put the hydrogen explosion particles in the jet mill, use high-pressure inert gas, and carry out jet milling treatment at 6-9 atm to prepare magnetic powder with an average particle size of 3 μm, and then Orientation pres...

Embodiment 2

[0039] 1) Melting ingots and quick-setting tablets: according to the nominal composition La 10 MM 21.5 Fe 66.1 M(Al 0.3 Cu 0.2 co 0.2 Ga 0.5 Zr 0.2 )B 1

[0040] (wt.%), select metal lanthanum and mixed rare earth MM (MM composition is Ce: 50%, La: 30%, Pr: 4%, Nd: 16%), iron, iron boron and other metals are placed in the crucible and It is filled with argon for smelting, and then poured onto a copper roller with a rotational speed of 5m / s to prepare a quick-setting thin strip with a thickness of 0.2-0.5mm.

[0041] 2) Hydrogen explosion, using a vacuum rotary hydrogen crushing furnace to carry out hydrogen explosion treatment on the quick-setting thin strips to obtain particles of uniform size.

[0042] 3) Jet milling, orientation pressing and isostatic pressing: put the hydrogen explosion particles in the jet mill, use high-pressure inert gas, and carry out jet milling treatment at 6-9 atm to prepare magnetic powder with an average particle size of 5 μm, and then O...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com