A concrete photovoltaic roof support system

A photovoltaic support and support system technology, applied in the support structure of photovoltaic modules, photovoltaic power generation, photovoltaic modules, etc., can solve the problems of inconvenient installation and transportation, slow construction progress, cumbersome construction, etc., to achieve convenient installation and transportation, avoid safety hazards, Effect of increasing wind resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

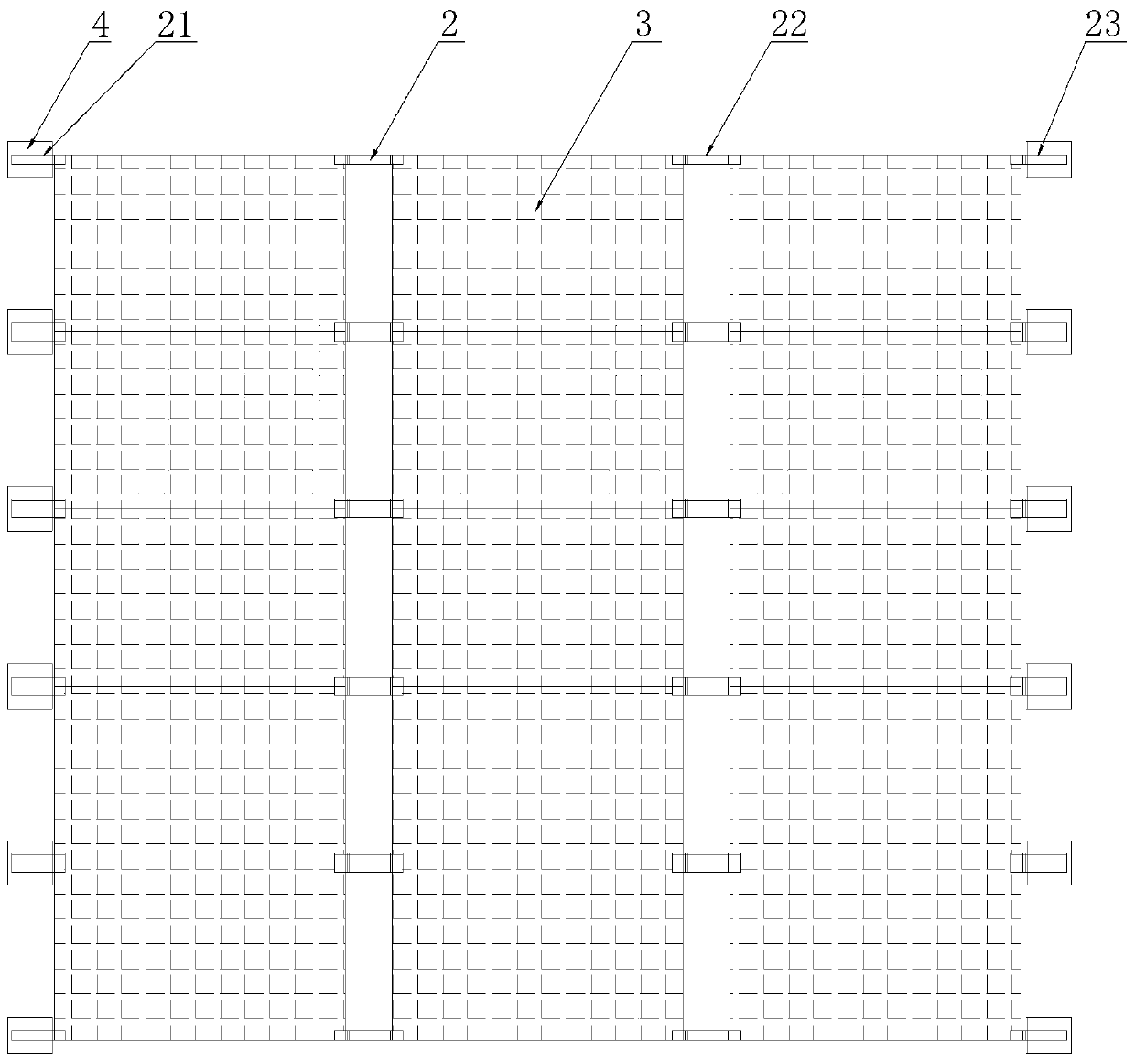

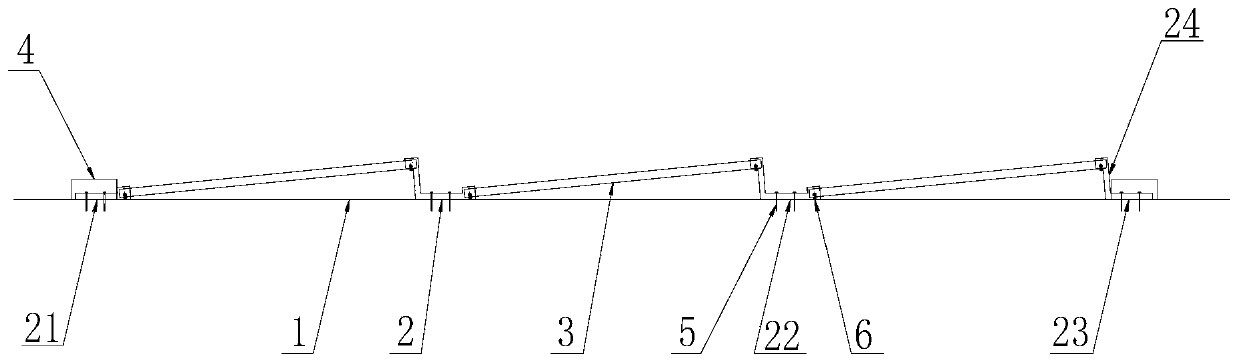

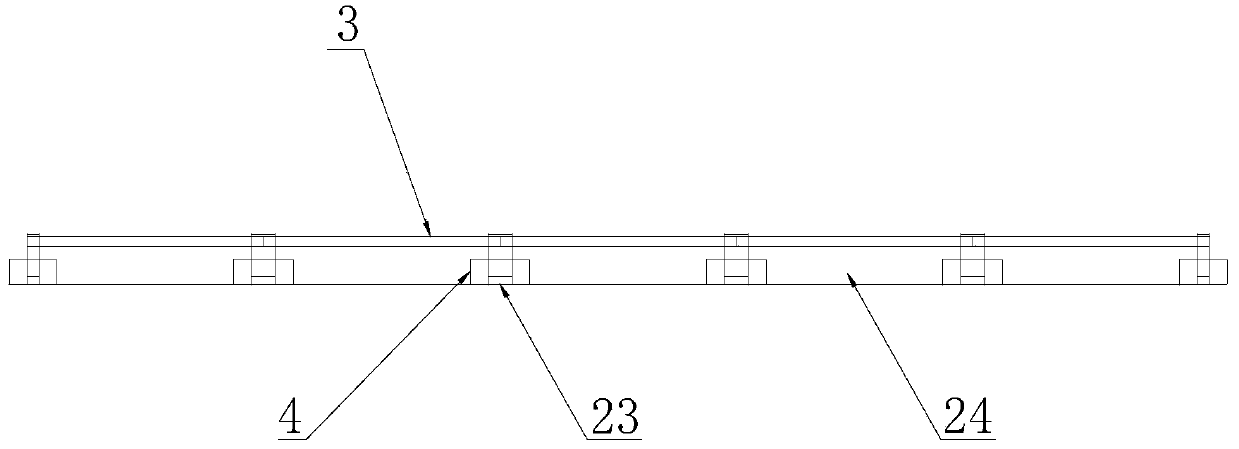

[0019] refer to Figure 1 to Figure 6 , a concrete photovoltaic roof support system of the present invention, including a base 1, a photovoltaic support 2, a photovoltaic module 3, a cement counterweight 4, self-tapping screws 5 and connectors 6, and the base 1 is provided with several photovoltaic supports 2 , the photovoltaic bracket 2 is provided with several self-tapping screws 5 and several connectors 6, the photovoltaic bracket 2 is installed and fixed on the base 1 through the self-tapping screws 5, and the two ends of the photovoltaic module 3 are connected through the connectors 6 is connected and fixed with the photovoltaic support 2. The photovoltaic assembly 3 forms an acute angle with the base 1 in the horizontal direction. The photovoltaic support 2 includes a first photovoltaic support 21, a second photovoltaic support 22 and a third photovoltaic support 23. The first A photovoltaic support 21 and a third photovoltaic support 23 are provided with cement counterw...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com