Artificial tooth self-repairing filling material

A technology of filling materials and dentures, which is applied in the field of denture restoration, can solve the problems of lack of perfect matching of concave-convex models, weak denture bonding, and bonding, so as to save time and labor, shorten the curing time of silica gel, and improve the quality of life. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

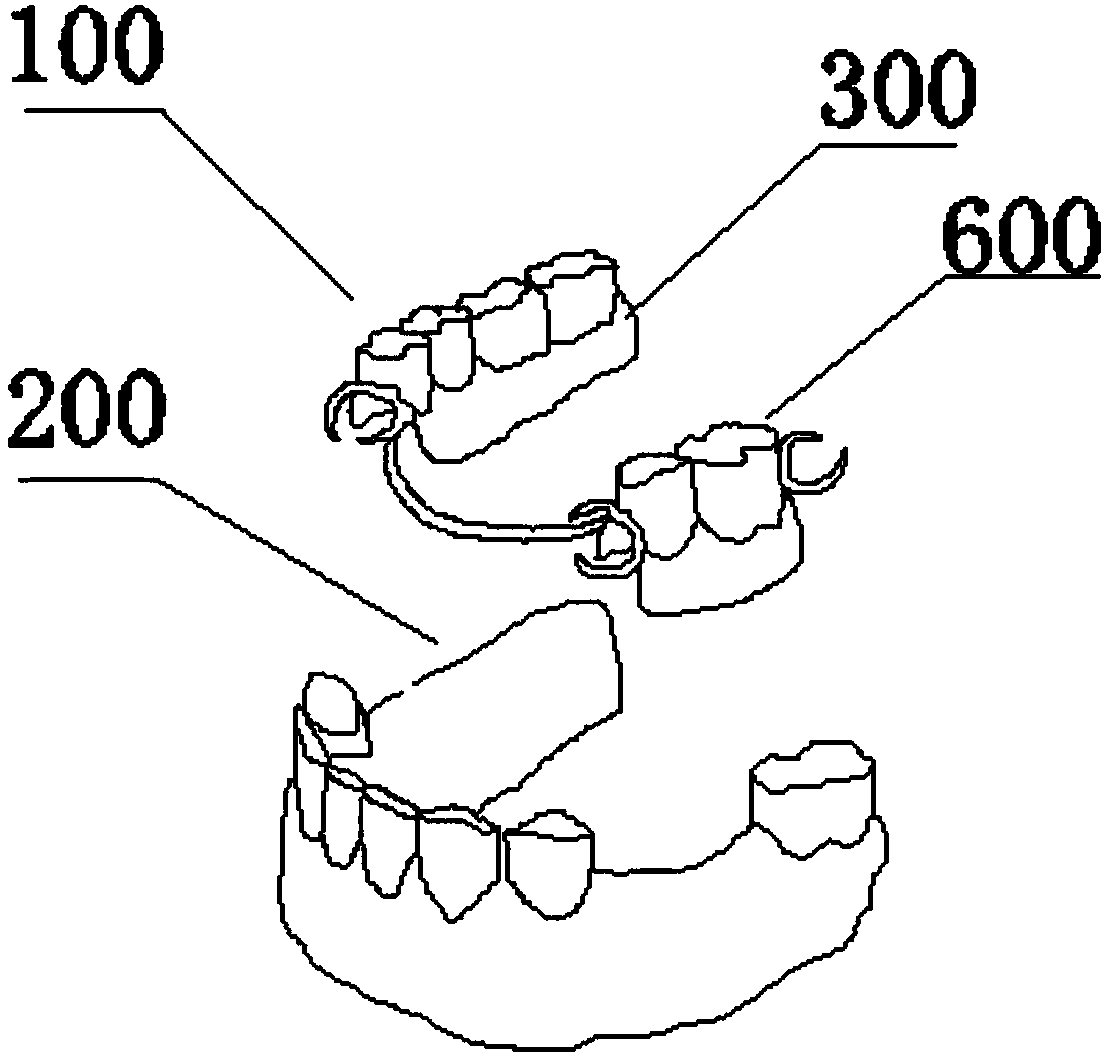

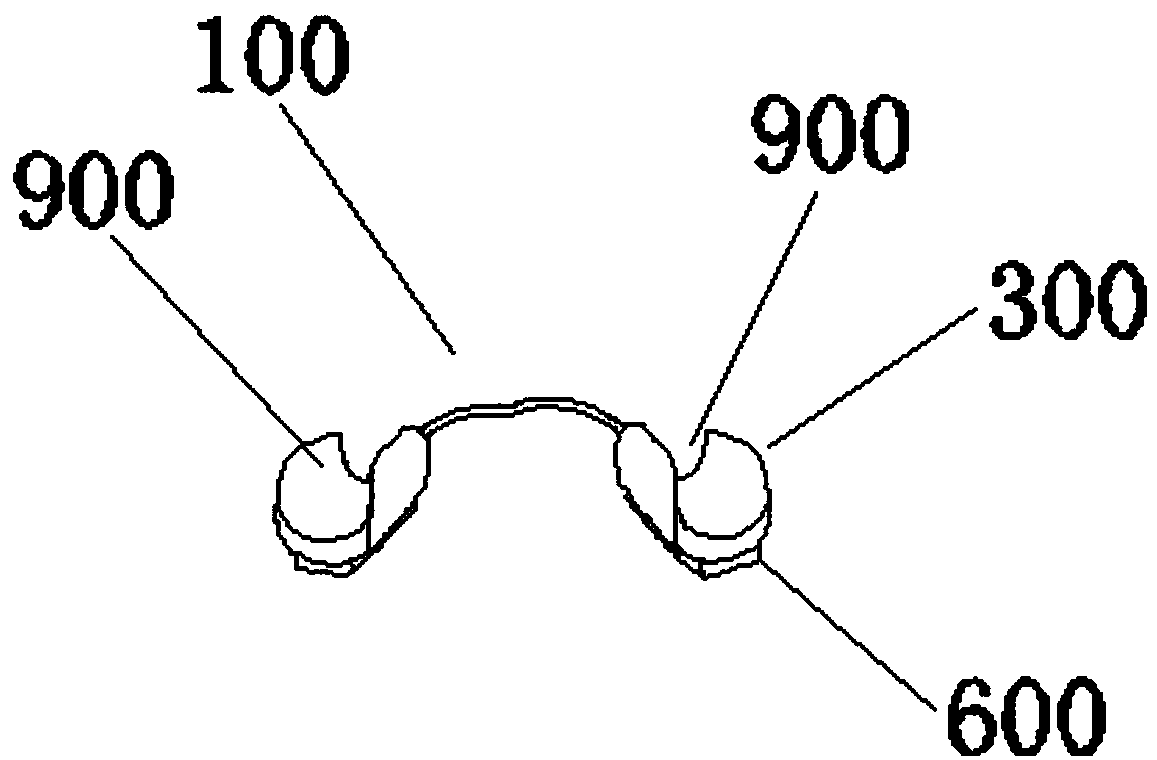

[0032] Example 1: Combining Figure 1-Figure 5 , a self-repairing filling material for dentures and a method for repairing them using the material: the first situation: removable removable dentures are closely inlaid with natural teeth, and the natural teeth are relatively stable, and the dentures are not easy to remove. Invention The technical solution is: direct filling with addition-type silica gel or room temperature vulcanized silica gel. The technical solution adopted is as follows, including the following steps:

[0033] 1) The denture is repaired according to the existing materials and technology, and all technological processes such as adjustment are completed;

[0034] 2), after the patient wears it comfortably for a period of time, repair and fill the denture: take out the removable denture 100 for cleaning and drying;

[0035] 3) Apply an appropriate amount of room temperature vulcanized silicone or addition-type liquid silicone on the concave surface 900 of the d...

Embodiment 2

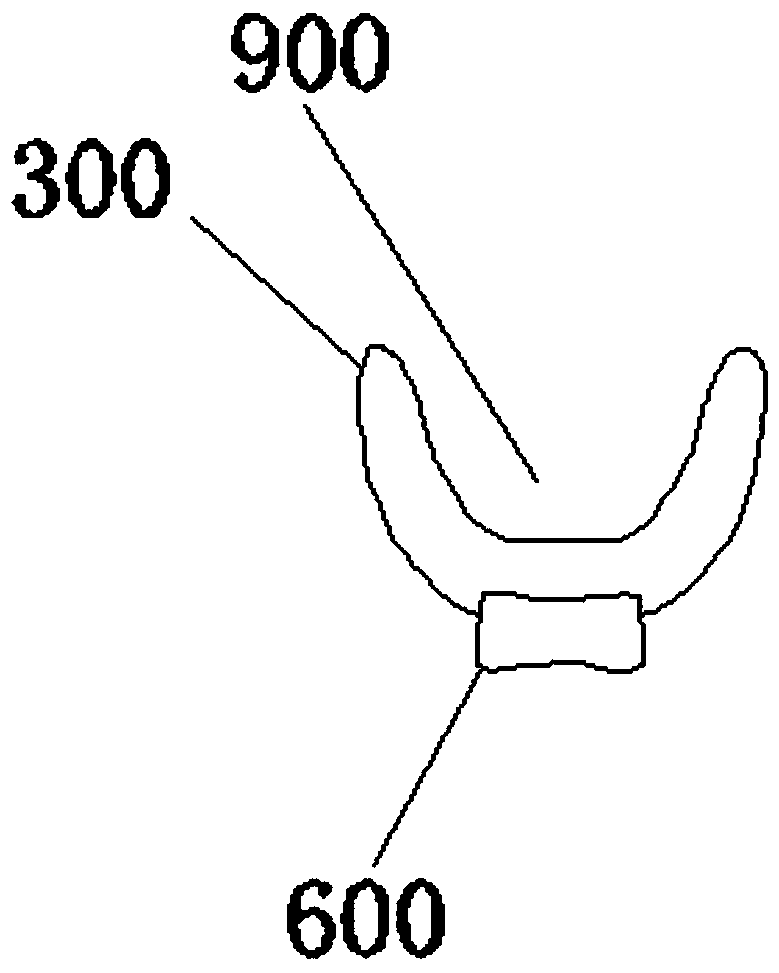

[0037] Example 2: Combining Figure 6 , a self-repairing filling material for dentures and a method of using the material for repairing: for the second case: such as total dentures, the dentures are easy to fall off by themselves, the technical solution invented is: use a single-component room temperature as an adhesive layer To bond the filling layer and the total denture together, the technical scheme adopted is as follows, including the following steps:

[0038] 1) The denture is repaired according to the existing materials and technology, and all technological processes such as adjustment are completed;

[0039] 2), after the patient wears it comfortably for a period of time, repair and fill the denture: take out the total denture 555 to clean and dry;

[0040] 3) Apply a layer of one-component room temperature vulcanized silica gel on the base concave surface 900 of the total denture 555 and the tissue surface 777 of the total denture as the adhesive layer 150

[0041] ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com