Dedicated rack for volute spraying

A hanger and volute technology, which is applied in the field of special hangers for volute spraying, can solve problems such as uneven spraying of workpieces, achieve the effects of easy promotion and use, reasonable structural design, and improved powder removal rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

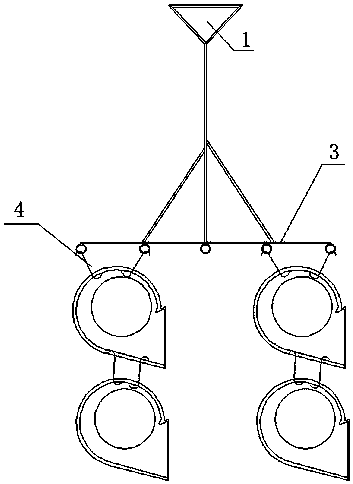

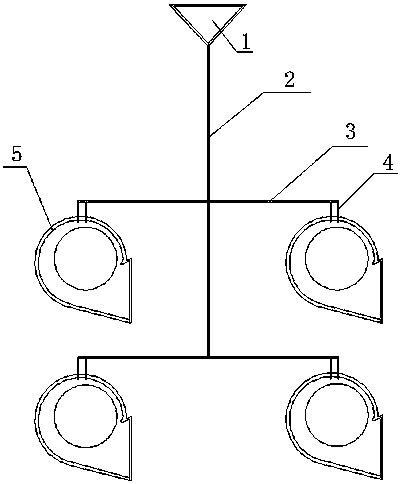

[0025] Such as figure 1 As shown, it is a schematic diagram of the volute hanger before improvement. The workpiece and the workpiece are connected by the S hook 4. When in use, two S hooks 4 are manually placed on the left and right sides of the fixed frame 3, and the lower part of the S hook 4 is suspended. Workpiece, place two S hooks 4 respectively again on the workpiece after hanging, then hang the workpiece again at the S hook 4 bottoms. Such a fixed frame can hang four products at a time, and the whole process needs to be hung 12 times. The manual operation is cumbersome and inefficient. Uniformity, there are four hanging points for a single workpiece on the upper layer, and the hanging points cannot be sprayed in place; during the powder removal process, because the S hooks are mixed together, it is difficult to remove the plastic powder on the surface, which reduces the electrical conductivity; the distance between the workpieces is too close There is a risk of collis...

Embodiment 2

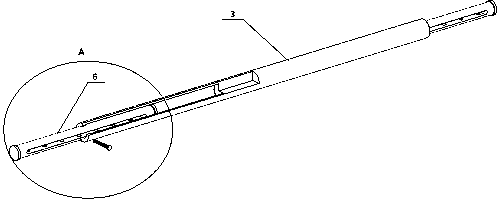

[0028] In order to broaden the scope of application of the hanger of the present invention to different types of products, on the premise of including the above content, the present invention can also be improved as follows: a sliding rod 6 that is slidingly connected to the fixed frame 3 is provided on both sides of the fixed frame 3, and the sliding rod 6 Can be sleeved inside or outside the fixed frame 3, in this embodiment, the sliding rod 6 is sleeved inside the fixed frame 3, and can slide freely in the fixed frame 3, the distance that the sliding rod 6 protrudes from the fixed frame 3 Firmware 7 is adjusted, such as fastening bolts etc., and the two ends of described sliding rod 6 and the two ends of fixed frame 3 are all provided with the step 63 that section increases, thereby limit the stroke of sliding rod 6, and sliding rod 6 Move along the direction away from the fixed frame 3 to the end of the fixed frame, which is the maximum stroke of the sliding rod 6; move the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com