High-strength high-tenacity bolt manufacturing method

A manufacturing method and high-toughness technology, applied in the field of bolt manufacturing, can solve the problems of short working life, poor ability to withstand shear force and impact force, limited working environment and use conditions, etc., to improve the usability and life, The effect of improving usability and practicality, and improving toughness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

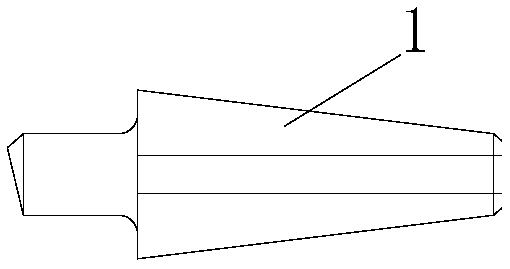

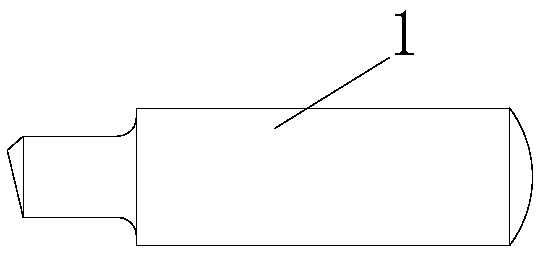

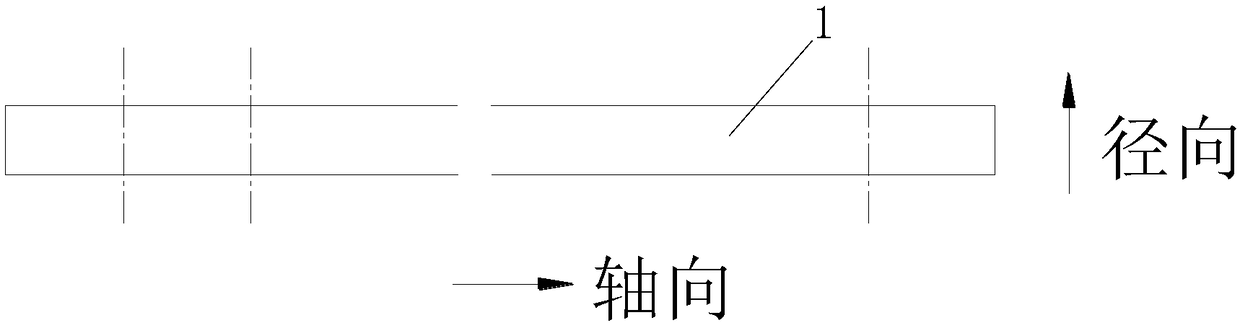

[0025] See Figure 1-Figure 5 , the manufacturing method of high-strength high-toughness bolt, comprises the following steps:

[0026] 1) Select 42CrMo steel ingot 1, use a 1000t~3000t hydraulic press to open the billet, and then use a 300t~500t hydraulic press to continue billeting, and then perform pre-drawing. The drawn steel ingot 1 is divided into several sections along the axial direction, and each section of steel ingot 1 Turning, the original radial direction is taken as the axial direction, and each section of steel ingot 1 is elongated along the axial direction after turning, forged and shaped, and then tempered after overall forging;

[0027] 2) Quenching and tempering treatment. The forged steel ingot 1 is heated in an electric furnace to 850° C. for 5 hours, and then quenched and tempered by oil quenching and tempering for 30 minutes. The tempering temperature is selected as 500°C, and the temperature is kept for 10h. After this process, the mechanical propertie...

Embodiment 2

[0030] See Figure 1-Figure 5 , the manufacturing method of high-strength and high-toughness bolts, the difference from Example 1 is that during the quenching and tempering treatment, the forged steel ingot 1 is heated in an electric furnace to 840 ° C for 5 hours, and then quenched in oil for 30 minutes, and then tempered immediately Quenching and tempering process; tempering temperature is controlled at 490 ℃, heat preservation 10h; finally choose thread rolling forming thread processing.

Embodiment 3

[0032] See Figure 1-Figure 5 , the manufacturing method of high-strength and high-toughness bolts, the difference from Example 1 is that during the quenching and tempering treatment, the forged steel ingot 1 is heated in an electric furnace to 860 ° C for 4.5 hours, and then quenched in oil for 35 minutes, and then tempered immediately Quenching and tempering process; tempering temperature is controlled at 510 ℃, heat preservation 11h; finally choose thread rolling forming thread processing.

PUM

| Property | Measurement | Unit |

|---|---|---|

| reduction of area | aaaaa | aaaaa |

| Brinell hardness | aaaaa | aaaaa |

| Brinell hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com