A Method for Minimizing Waste from Acid Heap Leach Mine Tailings Bank

A technology for mine tailings and tailings storage, applied in the field of uranium ore leaching, can solve the problems of reducing the degree of waste water minimization, equipment and pipeline corrosion, scarring, etc., to reduce production, reduce impurity content, and improve recovery rate Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

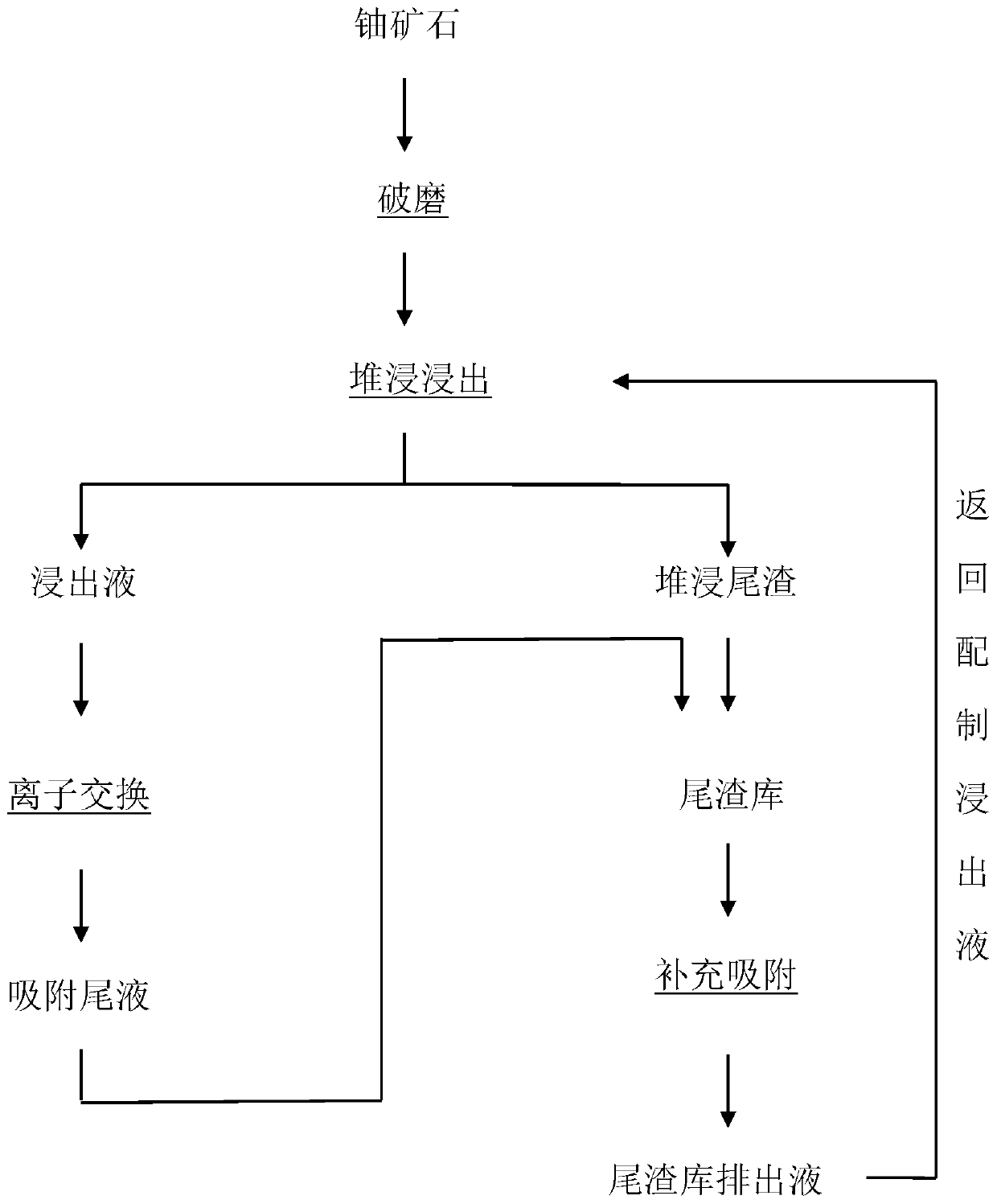

[0034] Such as figure 1 Shown, the method for making acid heap leaching mine tailings storehouse waste minimization described in the present invention, it comprises the steps:

[0035] (1) Crushing the uranium ore until the particle size is less than or equal to 6mm, and leaching the uranium ore according to the acid heap leaching process; the leaching agent used is sulfuric acid solution with a concentration of 30g / L, the oxidant is manganese dioxide, and the amount of manganese dioxide added is 1wt%;

[0036] (2) When the uranium concentration of the leaching solution of the uranium ore drops below 5 mg / L, the leaching is terminated;

[0037]The obtained leaching solution is subjected to ion exchange adsorption to extract uranium, using strong basic anion resin 201x7, using fixed bed or moving bed clear liquid ion exchange process, and the concentration of uranium in the final qualified liquid is greater than 10g / L; solvent extraction method is used to extract uranium, usin...

Embodiment 2

[0043] Such as figure 1 Shown, the method for making acid heap leaching mine tailings storehouse waste minimization described in the present invention, it comprises the steps:

[0044] (1) Crushing the uranium ore until the particle size is less than or equal to 4mm, and leaching the uranium ore according to the acid heap leaching process; the leaching agent used is a sulfuric acid solution with a concentration of 1g / L;

[0045] (2) When the uranium concentration of the leaching solution of the uranium ore drops below 5 mg / L, the leaching is terminated;

[0046] The obtained leaching solution is subjected to ion exchange adsorption to extract uranium, using strong basic anion resin 201x7, using fixed bed or moving bed clear liquid ion exchange process, and the concentration of uranium in the final qualified liquid is greater than 10g / L; solvent extraction method is used to extract uranium, using P204 extraction Sulfuric acid stripping agent, using single-stage or multi-stage ...

Embodiment 3

[0052] Such as figure 1 Shown, the method for making acid heap leaching mine tailings storehouse waste minimization described in the present invention, it comprises the steps:

[0053] (1) Crushing the uranium ore until the particle size is less than or equal to 8mm, and leaching the uranium ore according to the acid heap leaching process; the leaching agent used is sulfuric acid solution with a concentration of 50g / L, the oxidant is manganese dioxide, and the amount of manganese dioxide added is 2wt%;

[0054] (2) When the uranium concentration of the leaching solution of the uranium ore drops below 5 mg / L, the leaching is terminated;

[0055] The obtained leaching solution is subjected to ion exchange adsorption to extract uranium, using strong basic anion resin 201x7, using fixed bed or moving bed clear liquid ion exchange process, and the concentration of uranium in the final qualified liquid is greater than 10g / L; solvent extraction method is used to extract uranium, usi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com