Axial-flow-force multi-axis linked rolling curtain propeller provided giant wheel

A technology of multi-axis linkage and ferris wheel, which is applied in the field of axial flow wind wheel or water wheel power generation equipment, amusement park ferris wheel, and can solve the problems of difficult to bear strong wind, easy to fatigue, lose elasticity and break, difficult to install, etc. Achieve the effects of ensuring a safe transition to the storm period, saving winding time, and reducing manufacturing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

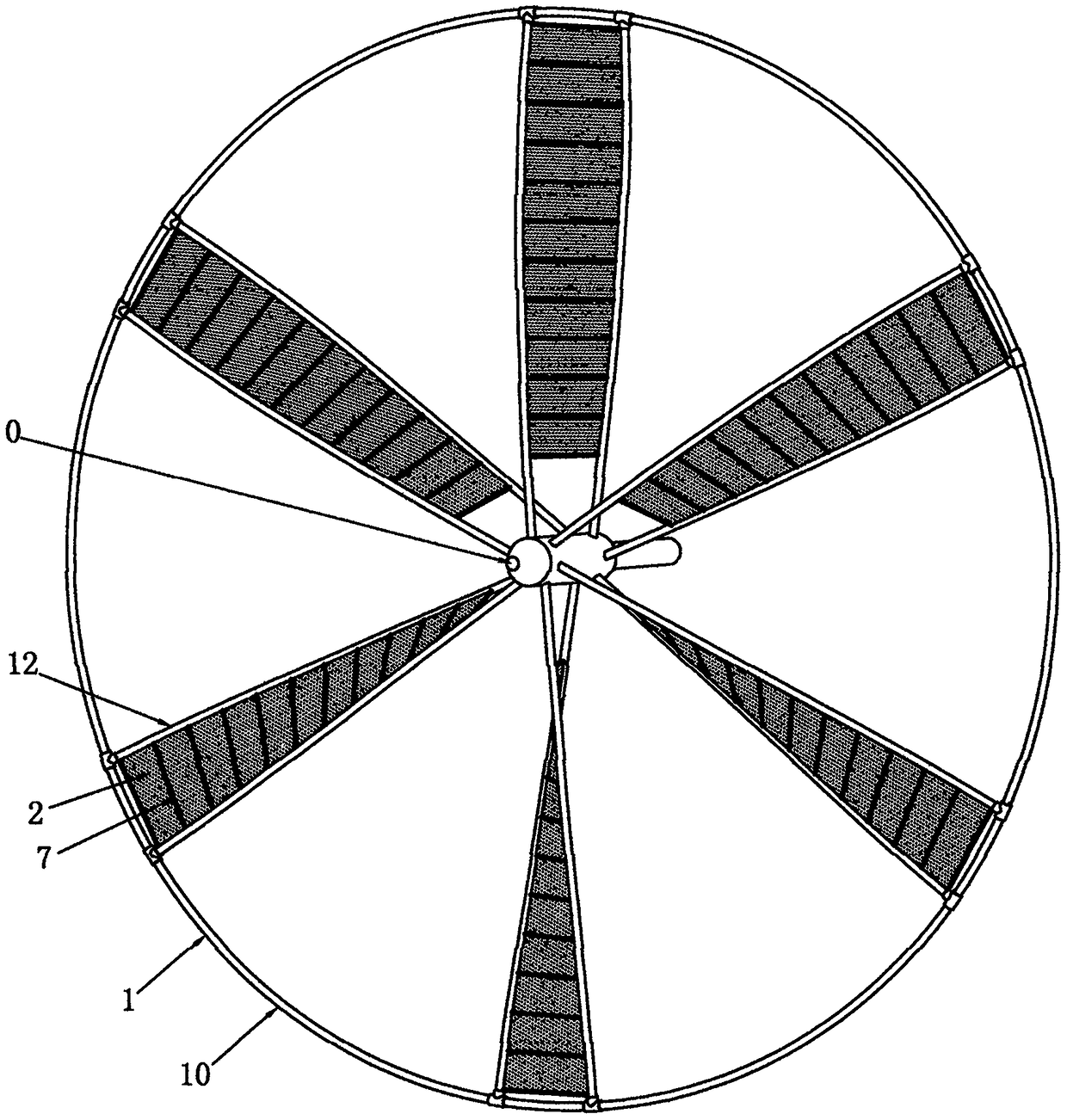

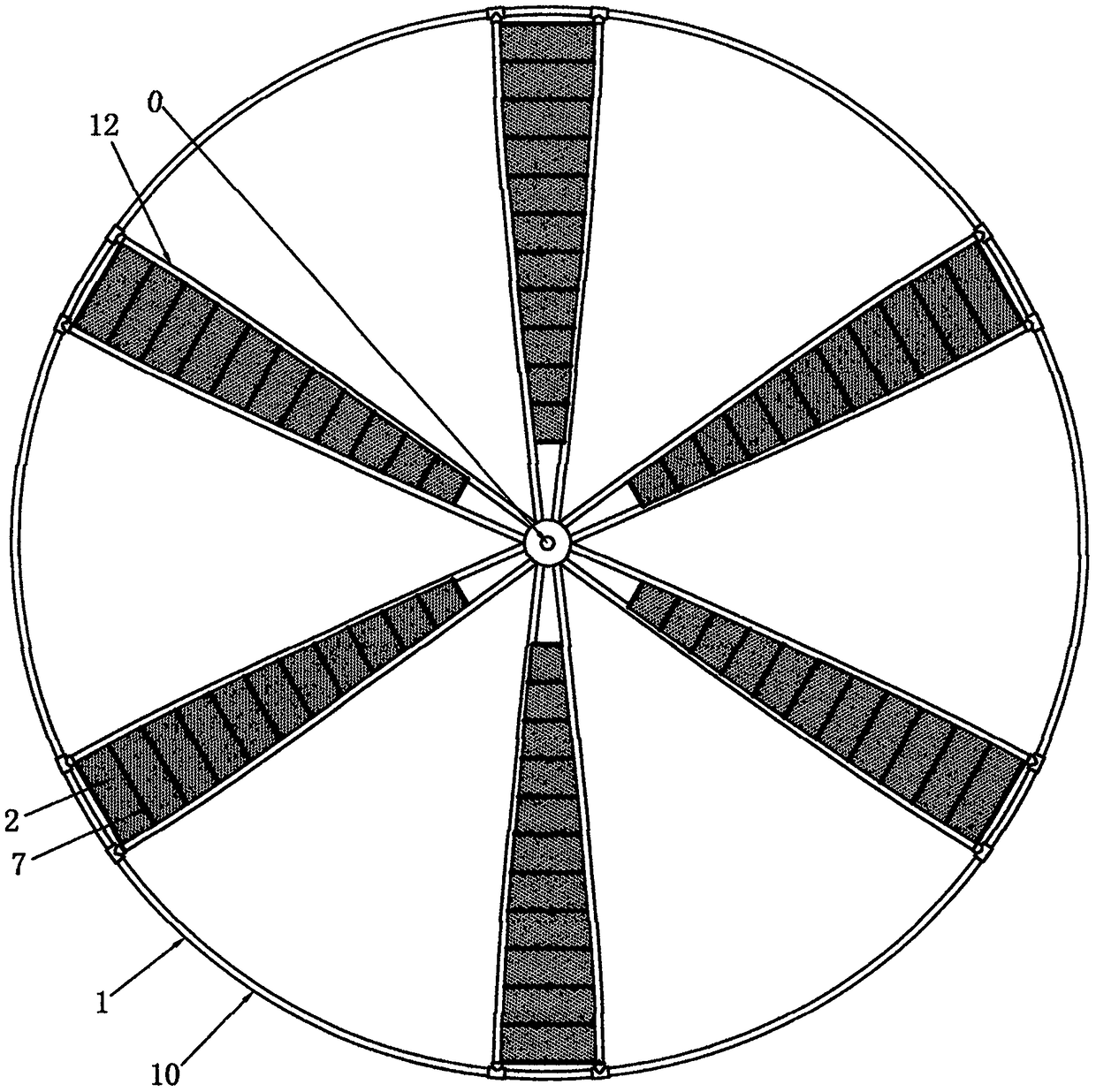

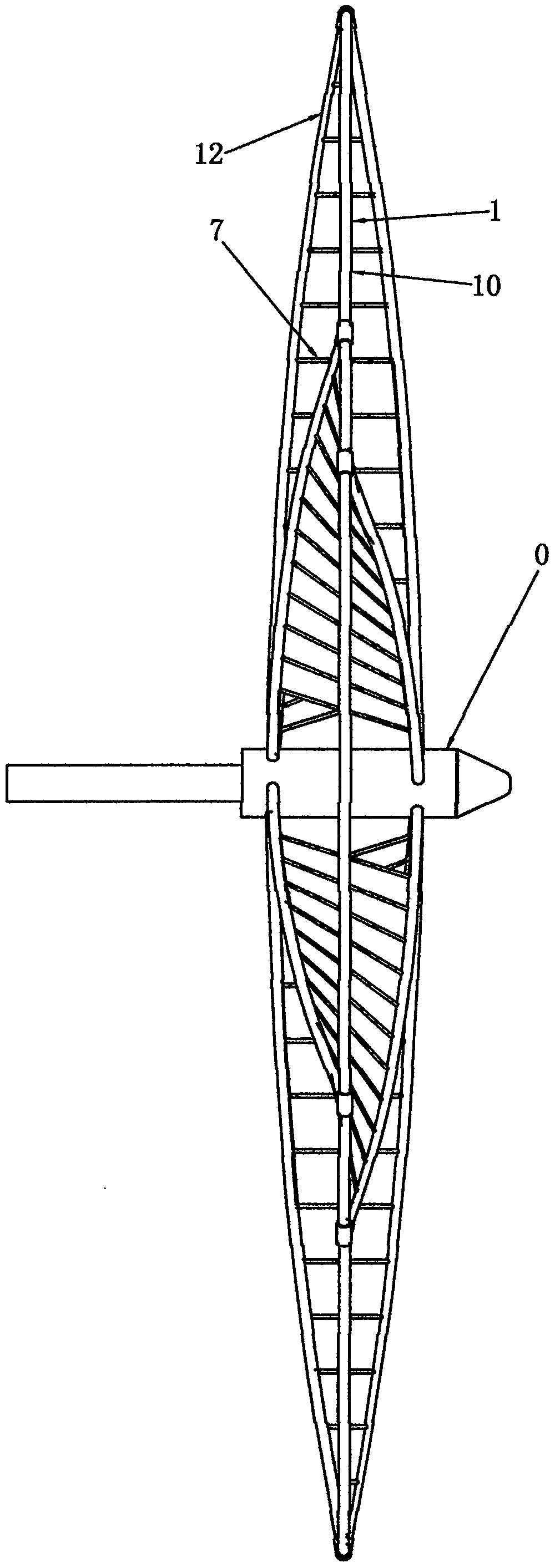

[0038] Axial flow force multi-axis linkage rolling shutter propeller Ferris wheel, such as figure 1 , 2 , 3, 4, 5, 6, 14, 15, 16, 17, including: Ferris wheel frame 1, roller blind 2, reel 7; said Ferris wheel frame 1 is composed of outer wheel 10, hub 0 and spokes The outer wheel 10 is at least a circle body, a triangle circle body, a star circle body, a polygon circle body, or a frame circle body; the spokes are the cable 11 or the brace 12 or the cable 11 and the brace The rods 12 are mixed and used; the cable 11 or the support rod 12 is connected to the hub with one end and the other end is connected to the outer wheel 10; and the cable 11 or the support rod 12 surrounds the hub. The inner circle of the annular array at the axial ends of the outer wheel 10 On the radial surface, the hub 0 and the outer wheel 10 are coaxially and concentrically formed to form a circular, triangular, star-shaped, or polygonal ferris wheel frame 1 on the radial surface; the spokes are diagonally...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com