Direct heating type air source floor radiation heat supply system construction method

A technology of radiant heating and construction method, applied in heating systems, heating methods, household heating and other directions, can solve the problems of high construction cost, rusted copper pipes, unsafe system operation, etc., and achieve safe equipment operation and control operation. , the effect of prolonging the service life and the safe operation of the system

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

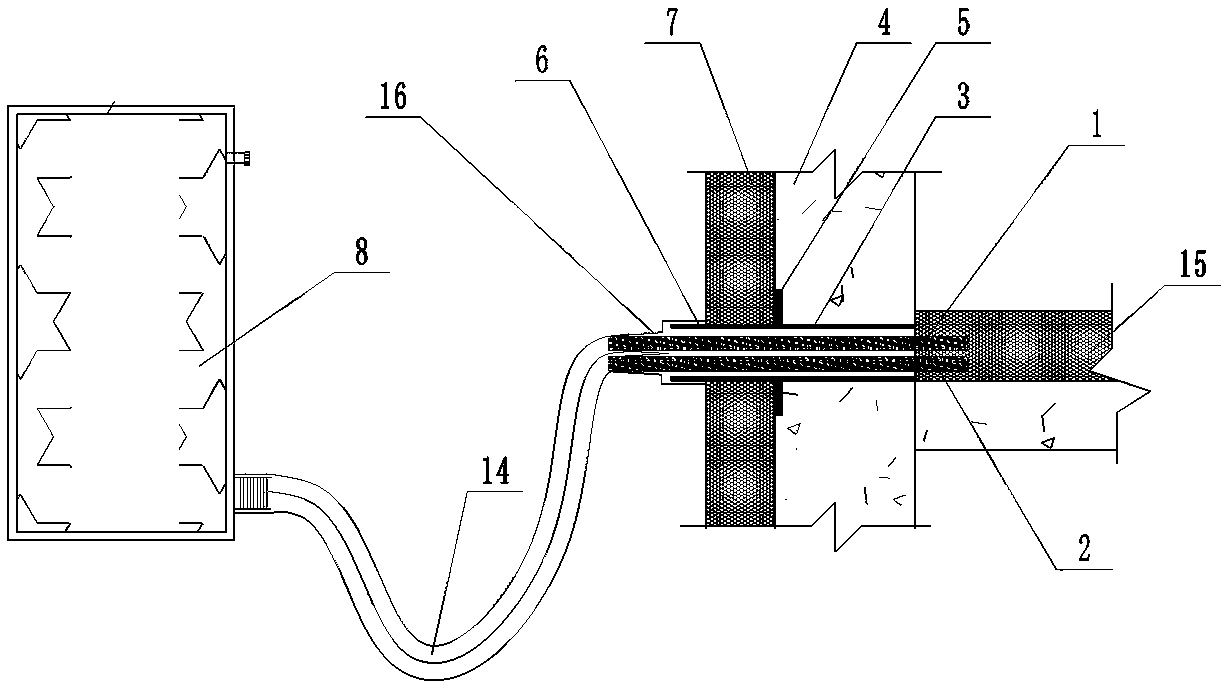

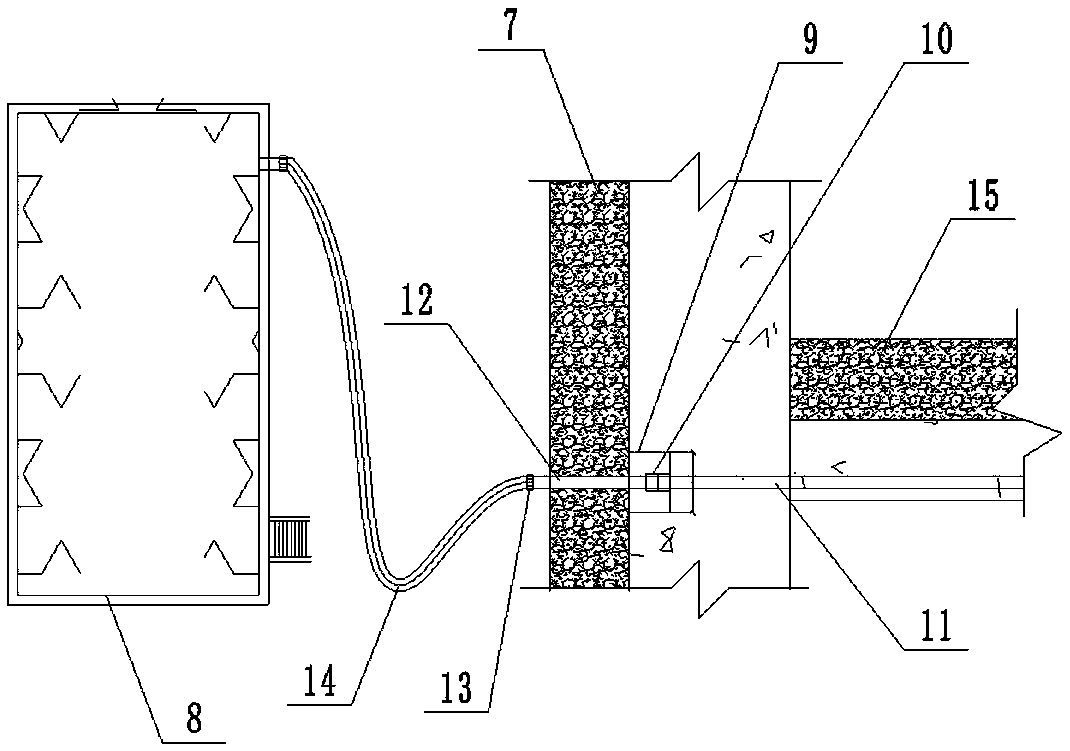

[0034] A typical implementation of the present invention provides a construction method for a direct-heating air source floor radiant heating system. The construction preparation includes:

[0035] 1. The design drawings and other technical documents are complete, there is a complete construction plan, and the technical disclosure has been reviewed and signed;

[0036] 2. The water and electricity conditions at the construction site are available, and there is a dedicated material storage site;

[0037] 3. The installers have undergone professional training, are familiar with the general performance of pipes, and master the basic operating points;

[0038] 4. The floor of the floor heating laying base is flat, clean, and dry. The closed water test of the kitchen and bathroom is qualified. The electrical pipelines must be dredged and threaded.

[0039] After the construction preparation is completed, proceed to the following steps:

[0040] Step 1, laying the heat insulat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com