Device and method for multi-directionally loading universal K-shaped nodes

A multi-directional loading and loading device technology, applied in measuring devices, using stable tension/pressure testing material strength, instruments, etc., can solve the problems of heavy workload, insufficient depth, single function of the test device, etc., to reduce the test cost, facilitate smooth progress, and improve test efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention will be further described in detail below in conjunction with specific embodiments, which are explanations of the present invention rather than limitations.

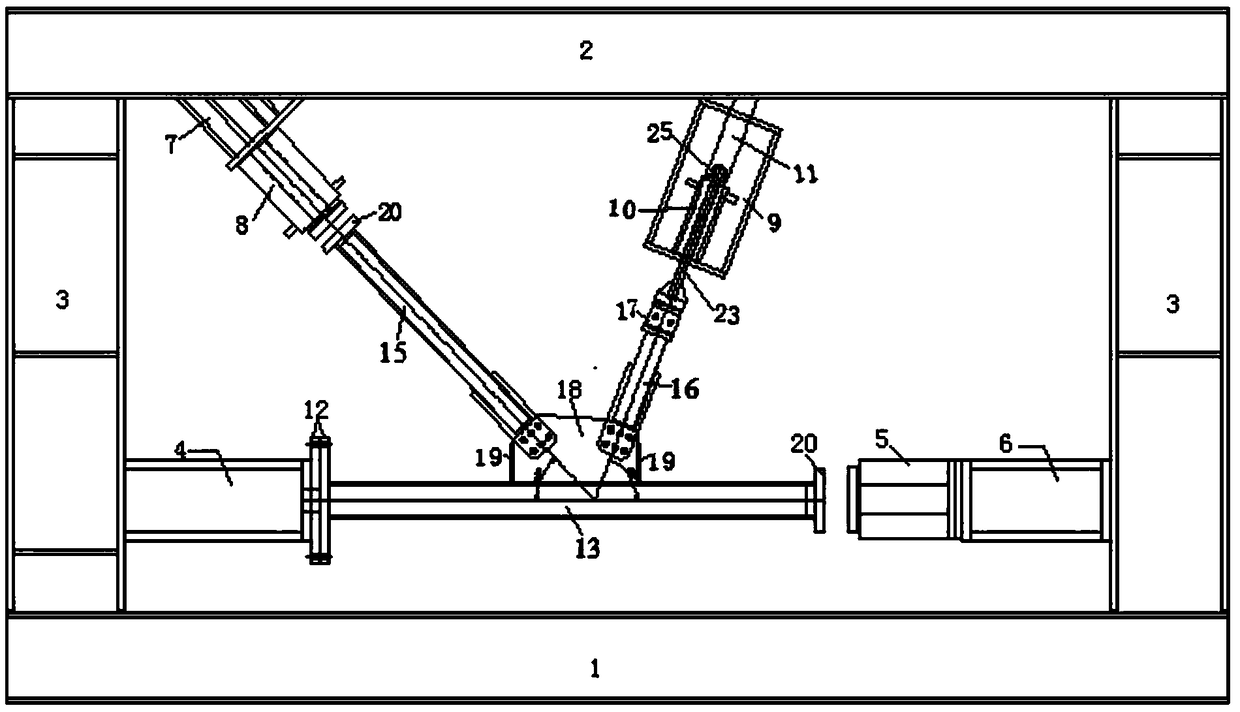

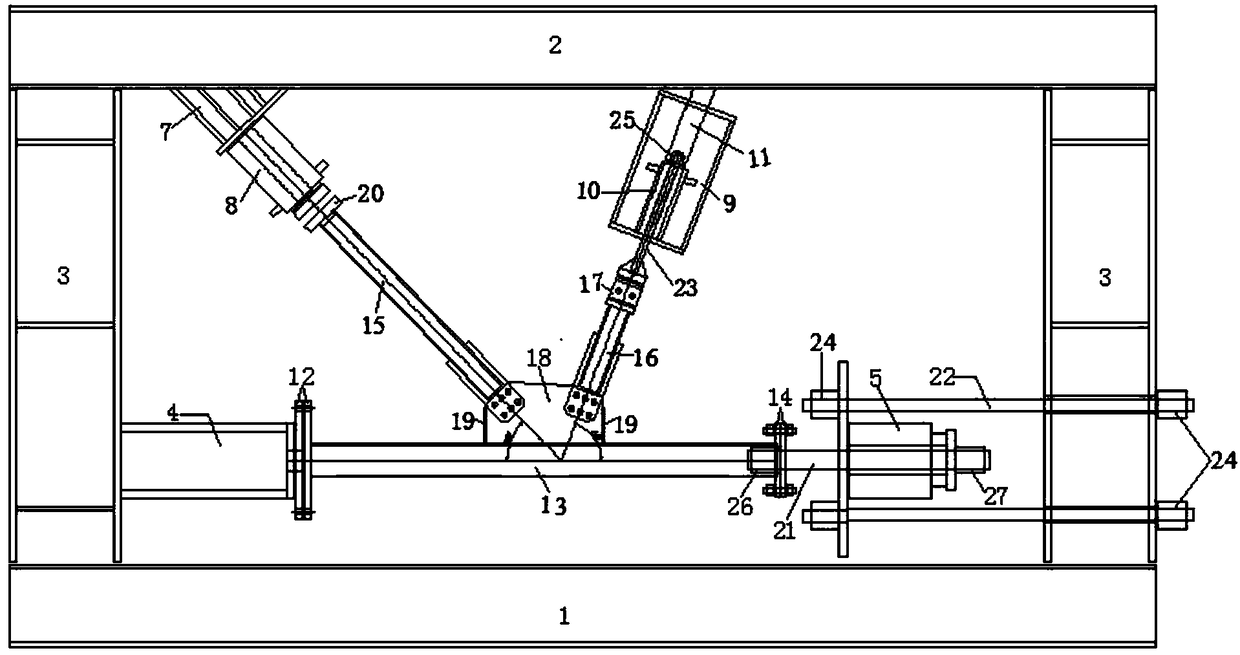

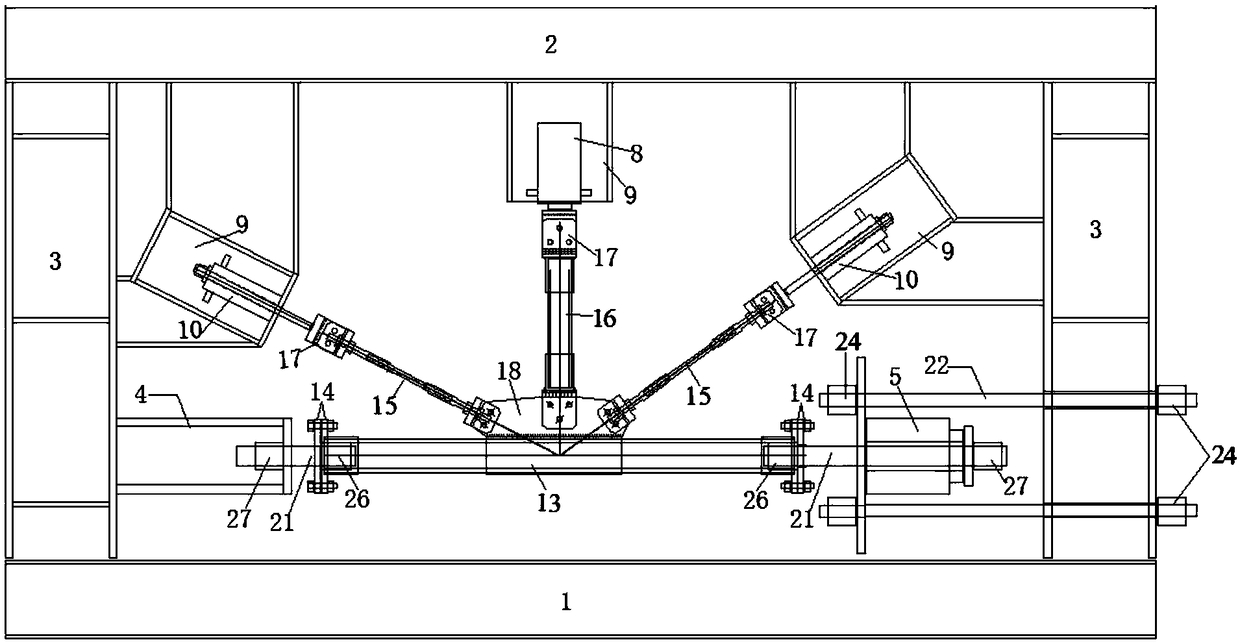

[0033] A kind of universal K-type node multidirectional loading device of the present invention, comprises such as figure 1 The general-purpose K-type node multi-directional compression loading device and such as figure 2 Universal K-node multi-directional pull loading device shown. The K-shaped joint is composed of a main material 13 and two auxiliary materials 15, 16. The main material 13 and the first and second auxiliary materials 15, 16 are connected by connecting plates 18 and bolts between the main material 13 and the first and second auxiliary materials. There is a ring plate 19 between the node pipes, and the axis of the node pipes intersects on the central axis of the main material; the connection between the hydraulic jack and the reaction force frame is connected by a pressure b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com