Method for predicting crack initiation life of high temperature alloy containing inclusion powder

A technology of life prediction and superalloy, applied in special data processing applications, instruments, electrical digital data processing, etc., can solve problems such as high cost, reverse thrust life, and inability to predict

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

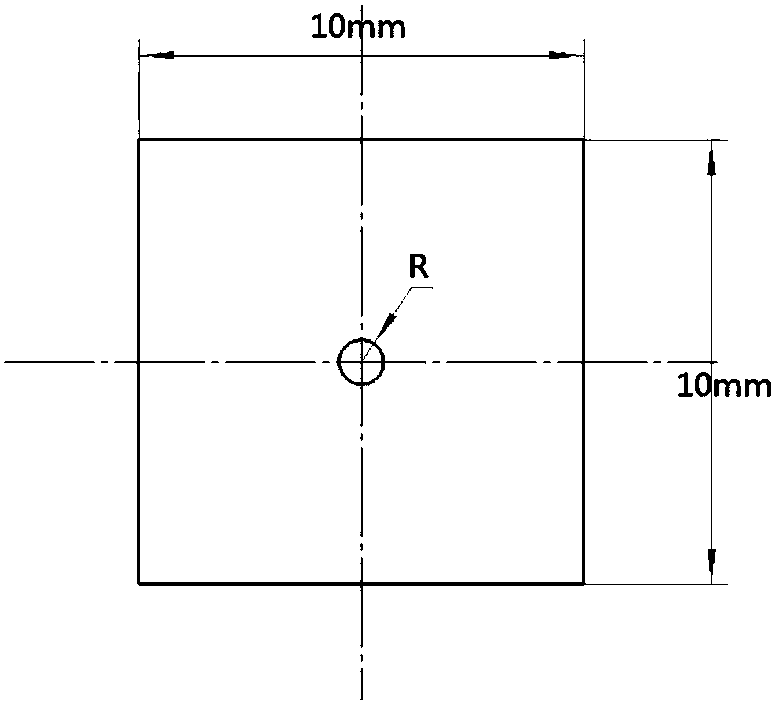

[0047] The component whose life expectancy is to be predicted is a flat-shaped component whose length and width are both 10 mm, and there is a circular aluminum oxide inclusion with a radius R of 100 microns in its center, and its geometric form is as follows: figure 2 shown. The component matrix material is FGH95 powder superalloy, its elastic modulus is E=193GPa, and Poisson’s ratio is 0.3; the central inclusion is set as a common alumina hard spherical inclusion in powder superalloy, and its elastic modulus is E 2 =400GPa, Poisson's ratio 0.3. Assuming that the member is subjected to far-field uniaxial tensile alternating loads, the maximum tensile strain is 0.8%, and the cycle characteristics are pulsating loads, that is, the maximum far-field tensile strain is 0.8%, and the minimum strain is 0.

[0048] 1. Define the damage variable field D(x i ,N):

[0049]

[0050] 2. Define the characteristic parameter Y as a function of the following strain components:

[0051...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com