Multi-stage distributed monitoring and diagnosis method for cigarette tobacco making process based on partitioning and stratifying thoughts

A technology of distributed monitoring and diagnosis method, applied in the registration/indication of manufacturing process, tobacco, preparation of tobacco, etc., can solve the problems of interference status monitoring, limiting the ability to capture concurrent abnormal information, not considering equipment status monitoring, etc. effect of ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

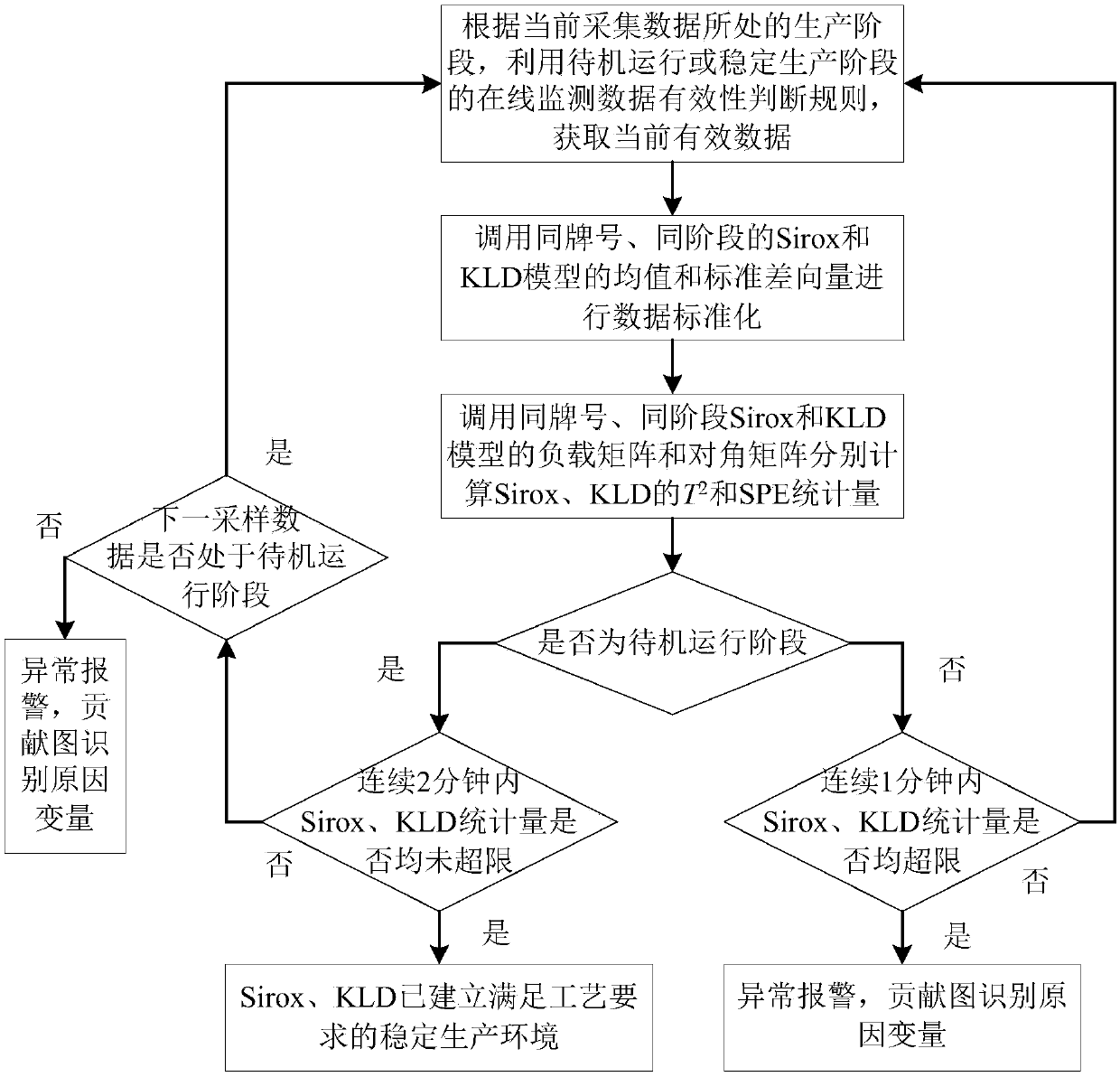

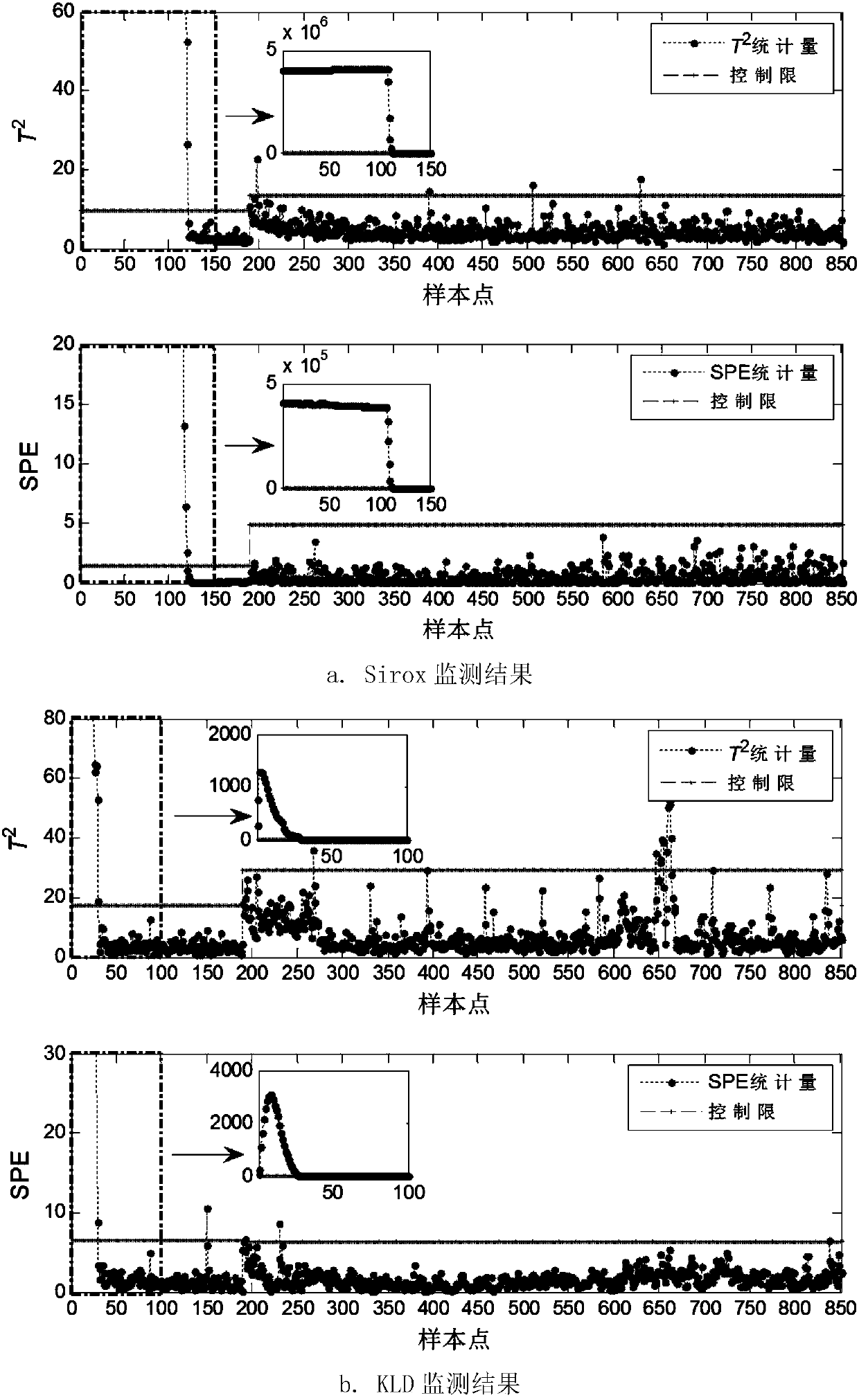

[0044] In order to better understand the technical solutions of the present invention, the implementation manners of the present invention will be further described below in conjunction with the accompanying drawings.

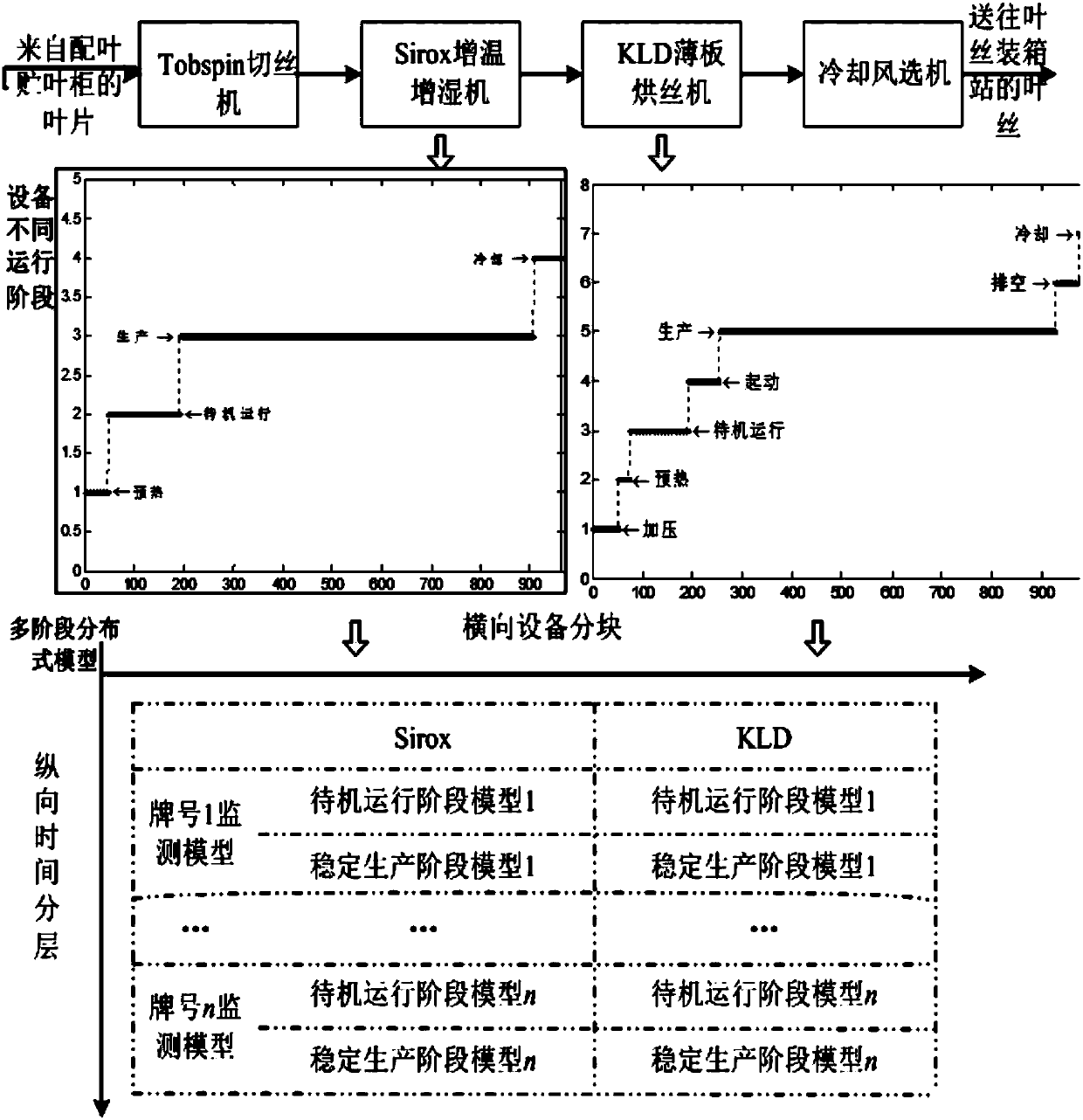

[0045] The invention is a key equipment unit used in the process of making shredded tobacco leaves: a Sirox warming and humidifying machine and a KLD thin plate shredded drying machine. The main function of the Sirox warming and humidifying machine is to expand and moisten the shredded leaves before drying, increase the temperature and moisture content of the shredded leaves, and increase the filling value of the shredded leaves after drying. The leaf silk reaches the air cyclone separator through the feed trough and the impeller gate. The shaft of the air cyclone separator is hollow and has a threaded hole on the shaft. The saturated steam flows out from the hole on the hollow shaft and falls on the shredded leaf, which makes the shredded leaf expand and moist...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com