A kind of sandalwood bark, bagasse fiber composite paper filter material and its preparation method and application

A bagasse fiber and paper-based technology, which is applied in applications, e-liquid filter elements, food science, etc., can solve problems such as poor odor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

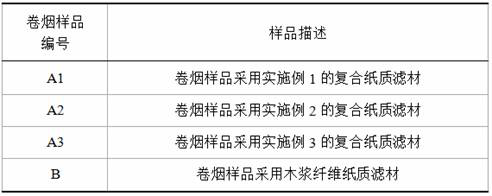

Examples

Embodiment 1

[0024] The preparation method of the sandalwood bark and bagasse fiber composite paper filter material of the present embodiment is prepared through the following steps:

[0025] (1) Preparation of paper base: Take commercially available sandalwood pulp board and bagasse paddle board according to the dry weight ratio of 6:4, and after hydropulping and dispersing, use PFI refiner to refine pulp. The concentration is 5% by mass, and the degree of beating is 35 ºSR. After adding conventional additives to the slurry, it is made on a paper sheet forming machine, and the paper sheet is dried for later use. The weight of the control paper is 37±1g / m2, and the thickness is 0.12±0.02 mm;

[0026] (2) Preparation of the coating liquid: take ebony and licorice according to the mass ratio of 7:3, mix and crush them, and then carry out heat reflux extraction with water to obtain the extract liquid. The solid-liquid ratio (w / v) during extraction is 1:30, and the extraction temperature is 6...

Embodiment 2

[0030] The preparation method of the sandalwood bark and bagasse fiber composite paper filter material of the present embodiment is prepared through the following steps:

[0031] (1) Preparation of paper base: Take commercially available sandalwood pulp board and bagasse paddle board according to the dry weight ratio of 9:1, and then use PFI refiner to refine the pulp after hydropulping and dispersing. The concentration is 8% by mass, and the degree of beating is 38 ºSR. After adding conventional additives to the slurry, it is made on a paper sheet forming machine, and the paper sheet is dried for later use. The weight of the control paper is 37±1g / m2, and the thickness is 0.12±0.02mm;

[0032] (2) Preparation of the coating liquid: Take black plum and licorice according to the mass ratio of 3:7, mix and crush them, and then carry out heat reflux extraction with water to obtain the extract liquid. The solid-liquid ratio (w / v) during extraction is 1:25, and the extraction tempe...

Embodiment 3

[0036] The preparation method of the sandalwood bark and bagasse fiber composite paper filter material of the present embodiment is prepared through the following steps:

[0037] (1) Preparation of paper base: Take commercially available sandalwood pulp board and bagasse paddle board according to the dry weight ratio of 8:2, and after hydropulping and dispersing, use PFI refiner to refine pulp. The concentration is 9% by mass, and the degree of beating is 42 ºSR. After adding conventional additives to the slurry, it is made on a paper sheet forming machine, and the paper sheet is dried for later use. The weight of the control paper is 37±1g / m2, and the thickness is 0.12±0.02 mm;

[0038] (2) Preparation of the coating liquid: Take black plum and licorice according to the mass ratio of 4:6, mix and crush them, and then heat reflux extraction with water to obtain the extract liquid. The solid-liquid ratio (w / v) during extraction is 1:35, and the extraction temperature is 60°C f...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com