Agglomeration device for heterogeneous condensation and turbulent agglomeration coupling and application thereof

A vapor phase, turbulent flow technology, applied in electrostatic effect separation, auxiliary pretreatment, solid separation and other directions, can solve problems such as unfavorable normal operation of equipment, affecting the development of front vortices, affecting the agglomeration effect, etc., achieving easy processing and promotion, simple installation, Increase the effect of fluid turbulence

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

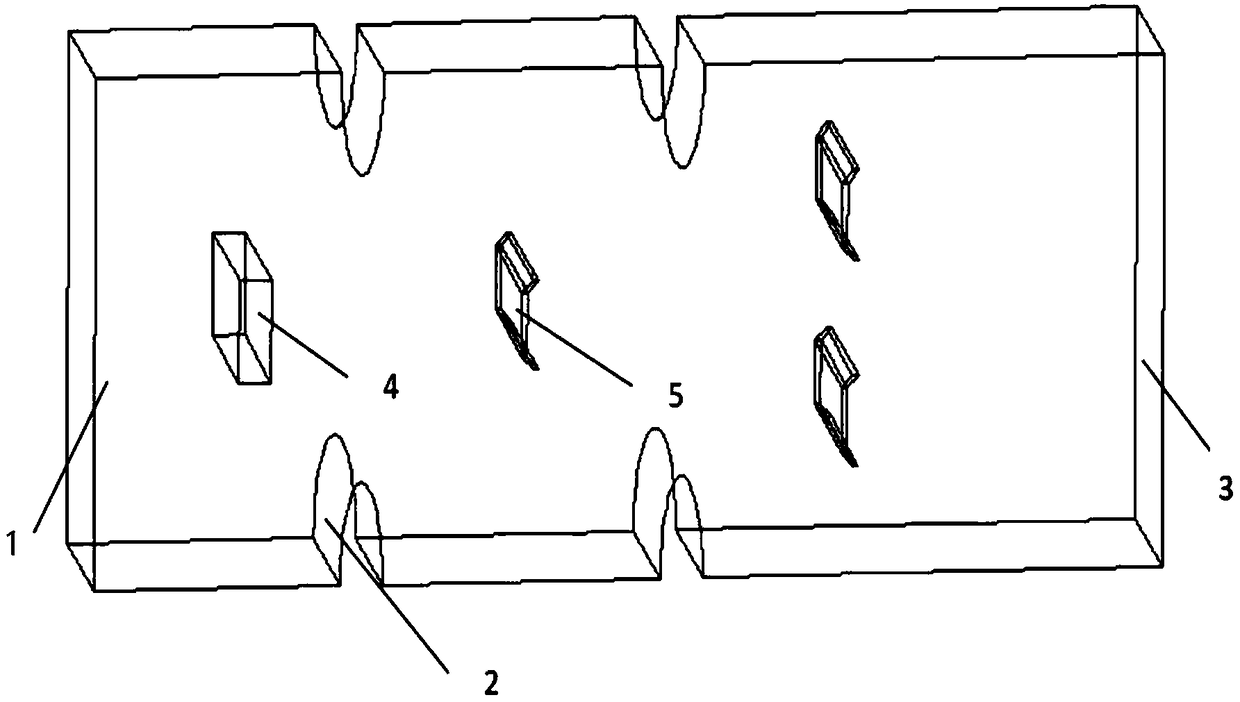

[0039] The agglomeration device in this embodiment is generally in the shape of a cuboid, but its boundary is provided with a semi-elliptical cylindrical protrusion, and the overall structure is axially symmetrical with respect to the direction of the incoming smoke. The left end of the reunion device is the flue gas inlet 1, which is connected to the desulfurization equipment, and the right end is the flue gas outlet 3, which is connected to the wet electrostatic precipitator. The interior of the agglomeration device includes a cuboid spoiler column 4 with the function of injecting steam and a C-shaped spoiler vortex 5. The center line of the cuboid spoiler column 4 with the function of injecting steam is located on the center line of the agglomeration device, and the cuboid spoiler column is close to the flue gas. The entrance position, its top view is a rectangle, the long side is perpendicular to the direction of flue gas flow, the first row of C-shaped spoiler vortex 5 is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com