Printing system for anti-counterfeiting two-dimensional code for packing card paper

An anti-counterfeiting printing and printing system technology, applied in the printing field, can solve problems such as error-prone, inconsistent printing of two-dimensional codes, delay in production, etc., and achieve the effect of low error rate production and guaranteed identity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

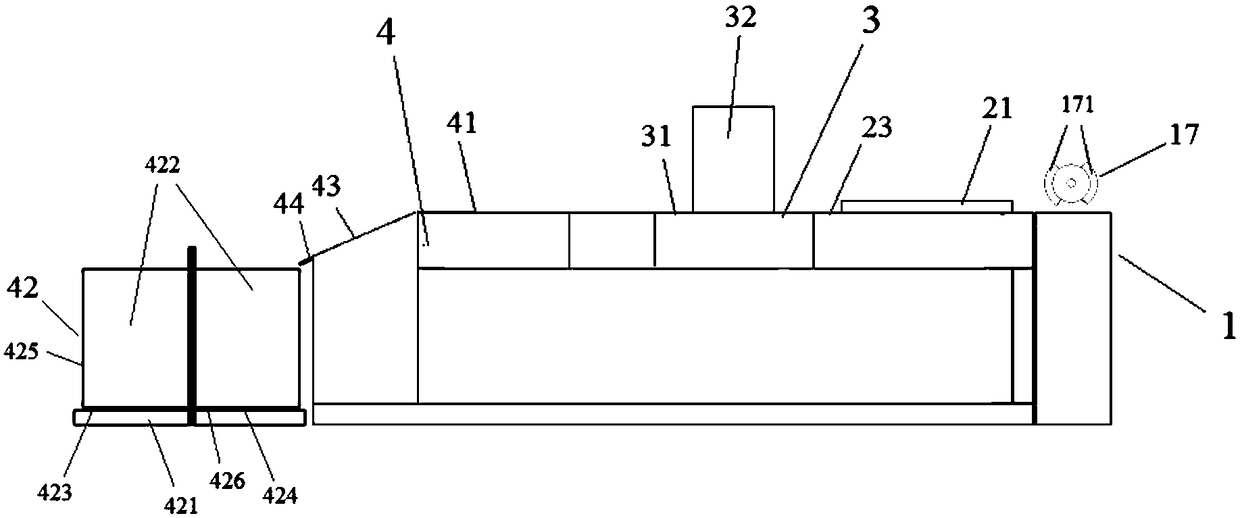

[0052] An anti-counterfeiting two-dimensional code printing system for packaging cardboard, its structure is as follows figure 1 shown, including:

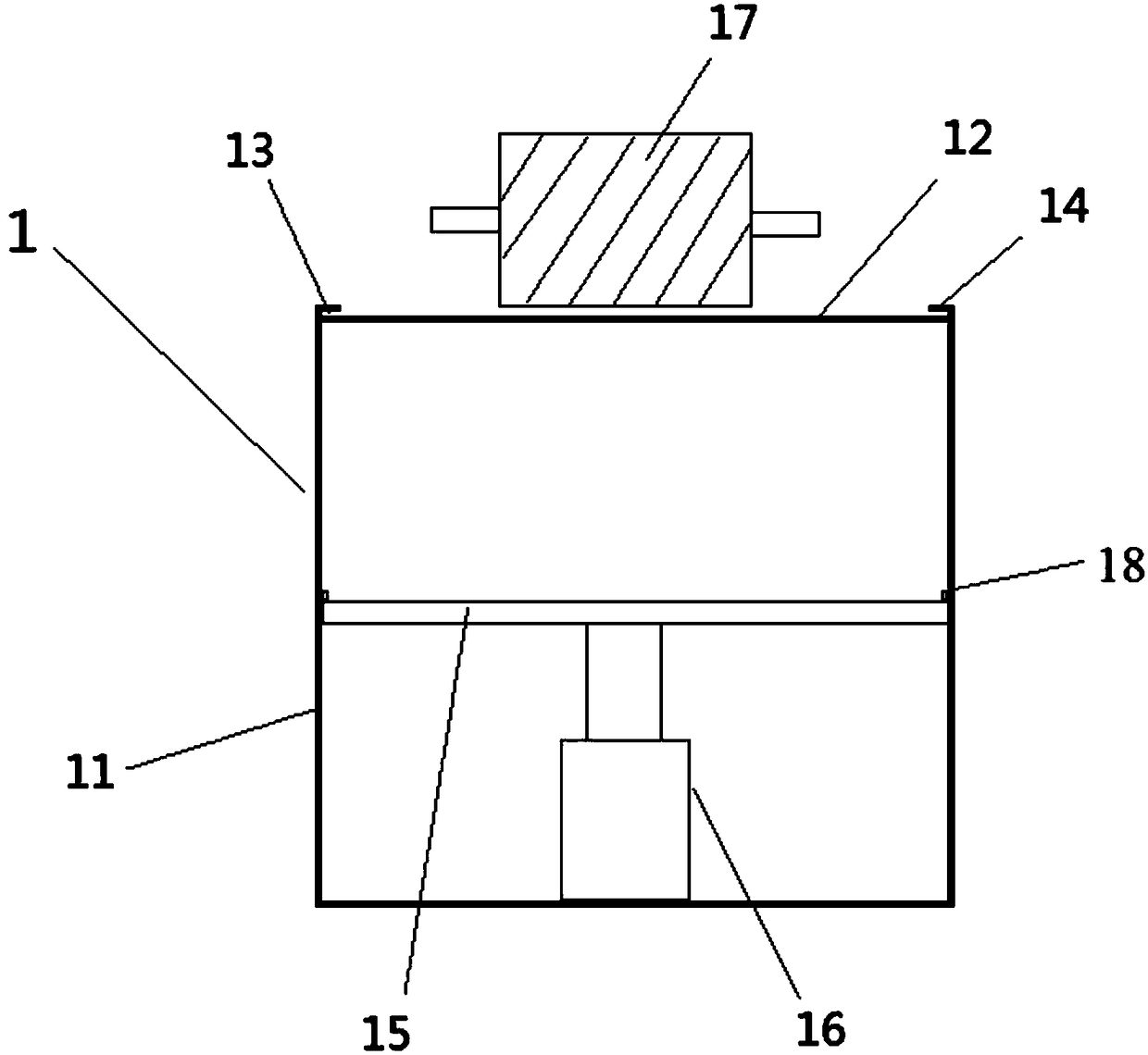

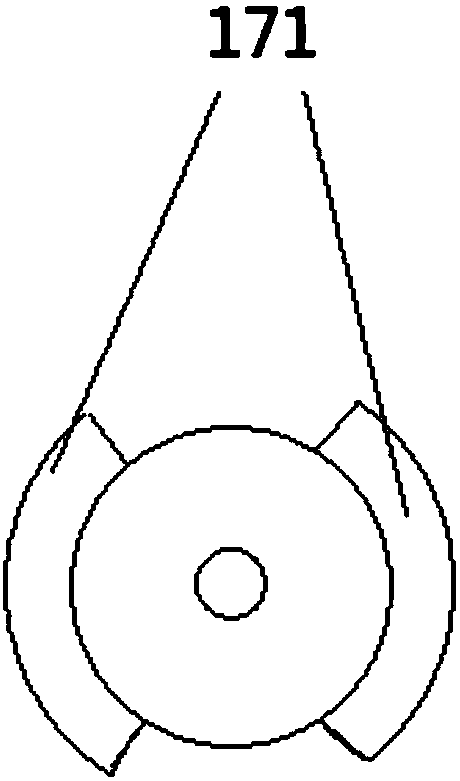

[0053] Feeding device 1: such as figure 2 As shown, it includes a paper feeding chamber, a paper release platform 15 arranged in the paper feeding chamber, and a paper feeding wheel 17 suspended above the paper feeding chamber. The paper feeding chamber is composed of two parallel longitudinal baffles 11 and a transverse baffle 12. It is surrounded by openings at its upper and lower ends and one side. The height of the transverse baffle 12 is smaller than that of the longitudinal baffle 11, and a paper inlet outlet is formed between the transverse baffle 12 and the longitudinal baffle 11. The inner wall of the cavity moves up and down, so that the packaging jam placed on the paper platform 15 can be resisted by the paper feed wheel 17 and taken out;

[0054] Paper guide 2: see Figure 4 and Figure 5As shown, it includes a pa...

Embodiment 2

[0068] On the basis of embodiment 1, this embodiment is further set to:

[0069] Both ends of the paper placing platform 15 protrude upward to form a limiting protrusion 18 whose height is not greater than the thickness of the packaging cardboard. The limit protrusion 18 can effectively prevent the contact friction between the paper placing platform and the paper feeding wheel. In addition, a pressure sensor is arranged on the lower surface of the limit stopper 14 , and the pressure sensor is connected to the first control unit in feedback, and the lifting unit 16 is also connected to the first control unit and controlled by it for lifting. In this way, through the pressure signal fed back by the pressure sensor, the second control unit can adjust the up and down degree of the lifting unit, thereby ensuring that the packaging jammed paper on the paper placing platform can not only effectively contact the paper feed wheel, but also prevent the paper from coming into contact wit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com