Diatomite water absorption plate and production method thereof

A technology of diatomite and water-absorbing boards, which is applied in the direction of sustainable waste treatment, solid waste management, climate sustainability, etc., can solve problems such as easy to breed mold, easy to become slippery, difficult to walk, etc., to reduce noise Harm to the body, obvious effect, shortening time effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

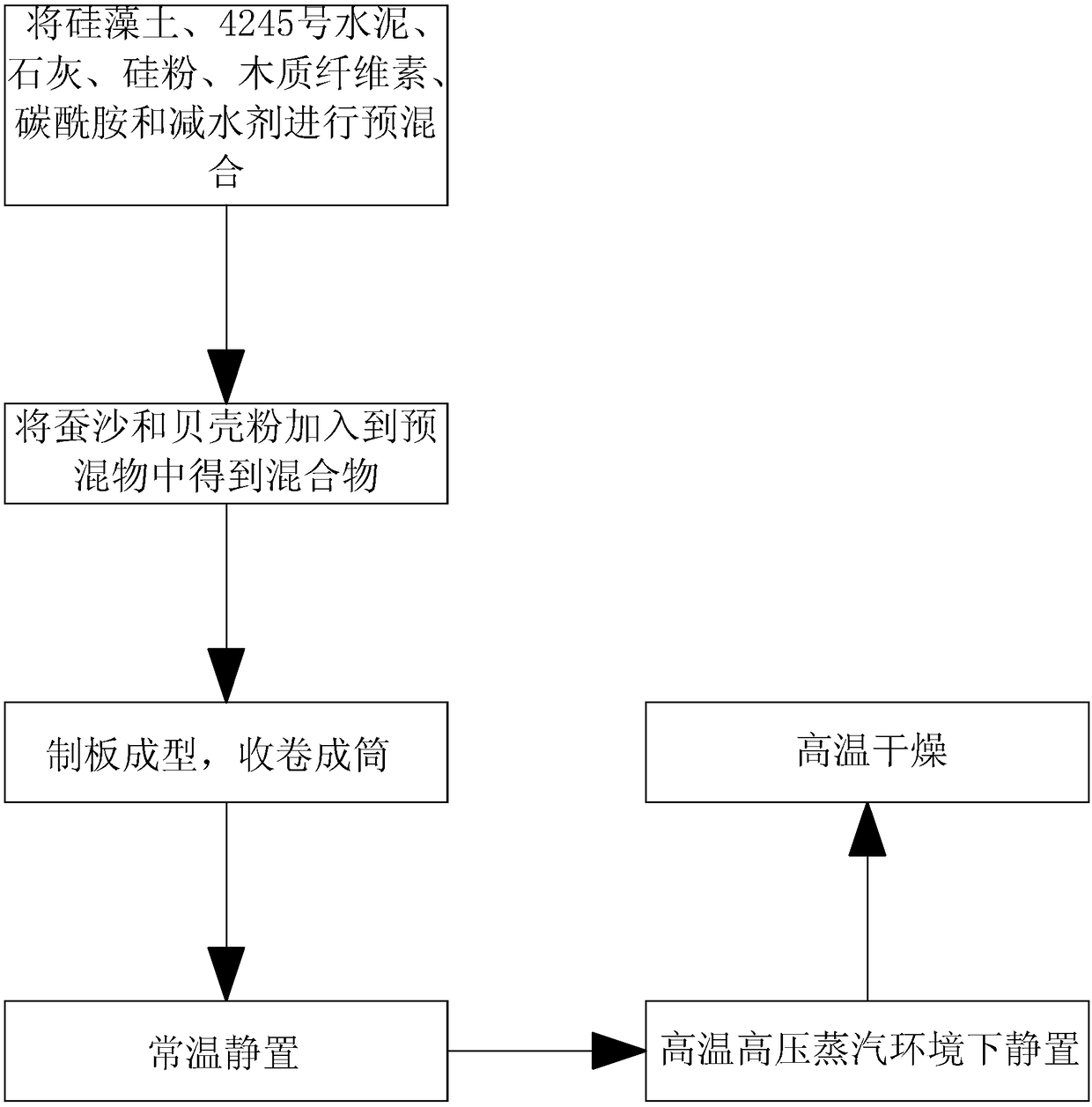

Method used

Image

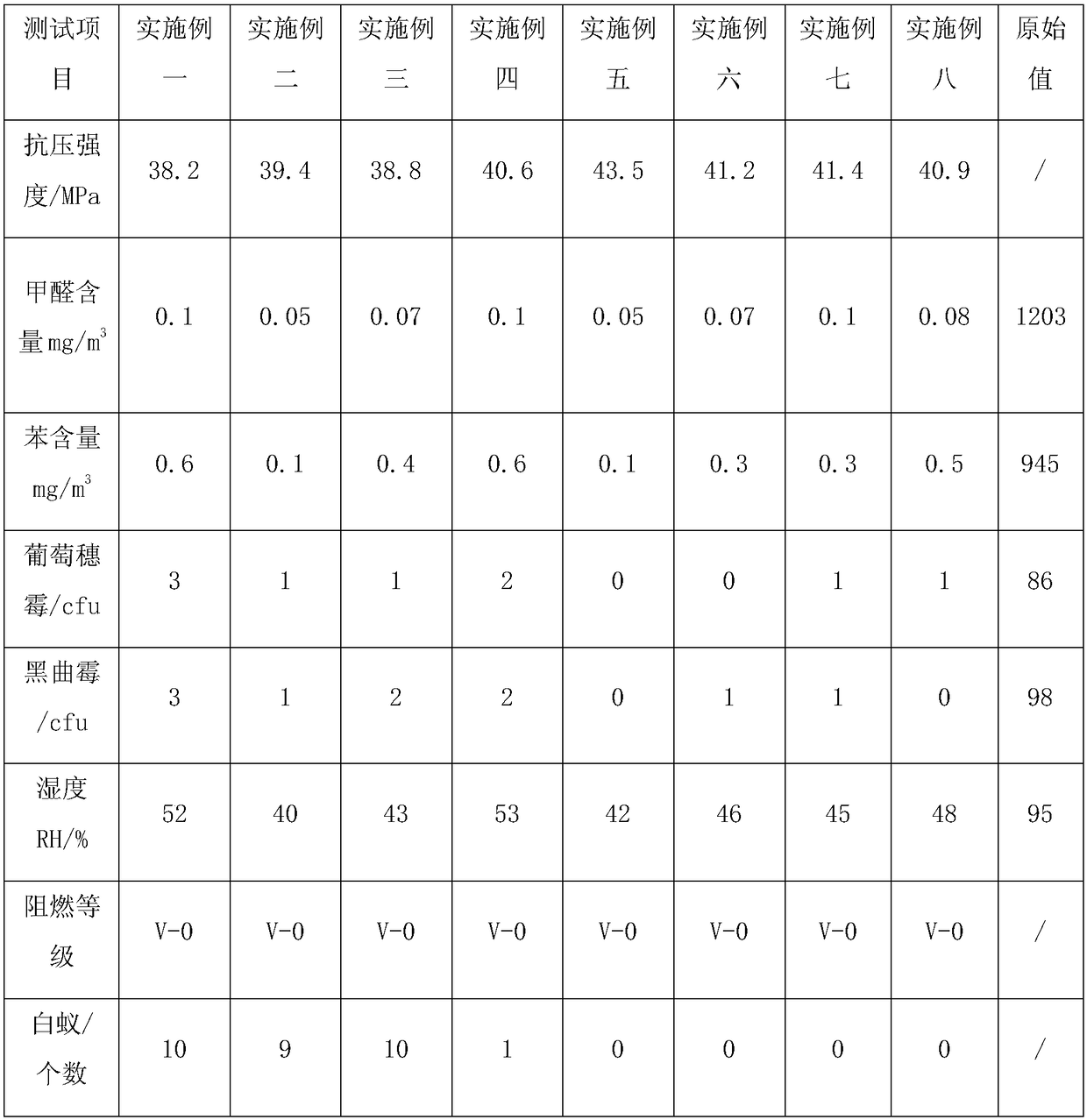

Examples

Embodiment 1

[0050] A preparation method of a diatomite water-absorbing board, comprising the following steps:

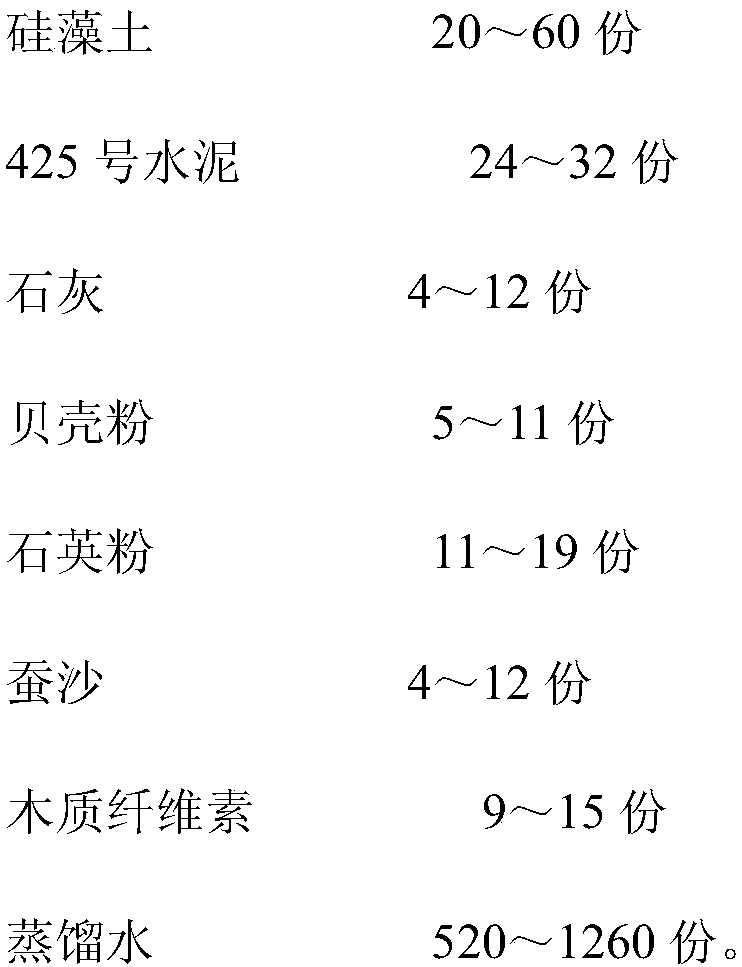

[0051] S1. Add 20Kg of diatomite, 24Kg of No. 425 cement, 4Kg of lime, 11Kg of quartz powder and 9Kg of lignocellulose into the mixer, and add 520Kg of distilled water for premixing. The stirring speed is 500rpm and the duration is 15min. and get the premix;

[0052] S2. Add 5Kg of shell powder and 4Kg of silkworm excrement with a specification of 600-1200 mesh to the premix of S1, and continue to stir for 15min at a stirring speed of 800rpm to obtain a mixture;

[0053] S3, adding the mixture to the forming device for plate forming, wherein the linear speed of the formed plate output is 50m / min, and the number of turns of the formed plate is 18 turns / tube;

[0054] S4. Transport the reeled formed sheet to a clean storage box for storage, and spread out the whole tube of formed sheet, and let it stand at room temperature for 6 hours;

[0055] S5. Introduce water vapor into the...

Embodiment 2

[0061] A preparation method of a diatomite water-absorbing board, comprising the following steps:

[0062] S1. Add 60Kg of diatomite, 32Kg of No. 425 cement, 12Kg of lime, 19Kg of quartz powder and 15Kg of lignocellulose into the mixer, and add 1260Kg of distilled water for premixing. The stirring speed is 500rpm and the duration is 15min. and get the premix;

[0063] S2. Add 11Kg of shell powder and 12Kg of silkworm excrement with a specification of 600-1200 mesh to the premix of S1, and continue stirring for 15 minutes at a stirring speed of 800rpm to obtain a mixture;

[0064] S3, adding the mixture to the forming device for plate forming, wherein the linear speed of the formed plate output is 50m / min, and the number of turns of the formed plate is 18 turns / tube;

[0065] S4. Transport the reeled formed sheet to a clean storage box for storage, and spread out the whole tube of formed sheet, and let it stand at room temperature for 6 hours;

[0066] S5. Introduce water vap...

Embodiment 3

[0072] A preparation method of a diatomite water-absorbing board, comprising the following steps:

[0073] S1. Add 36Kg of diatomite, 29Kg of No. 425 cement, 8Kg of lime, 15Kg of quartz powder and 13Kg of lignocellulose into the mixer, and add 890Kg of distilled water for premixing. The stirring speed is 500rpm and the duration is 15min. and get the premix;

[0074] S2. Add 9Kg of shell powder and 9Kg of silkworm excrement with a specification of 600-1200 mesh to the premix of S1, and continue stirring for 15 minutes at a stirring speed of 800rpm to obtain a mixture;

[0075] S3, adding the mixture to the forming device for plate forming, wherein the linear speed of the formed plate output is 50m / min, and the number of turns of the formed plate is 18 turns / tube;

[0076] S4. Transport the reeled formed sheet to a clean storage box for storage, and spread out the whole tube of formed sheet, and let it stand at room temperature for 6 hours;

[0077] S5. Introduce water vapor i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com