Pollutant removing device for sewage pipe

A technology for sewage pipelines and cleaning, which is applied in water supply installations, waterway systems, buildings, etc., and can solve problems such as low operation efficiency, poor working environment, and high labor intensity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

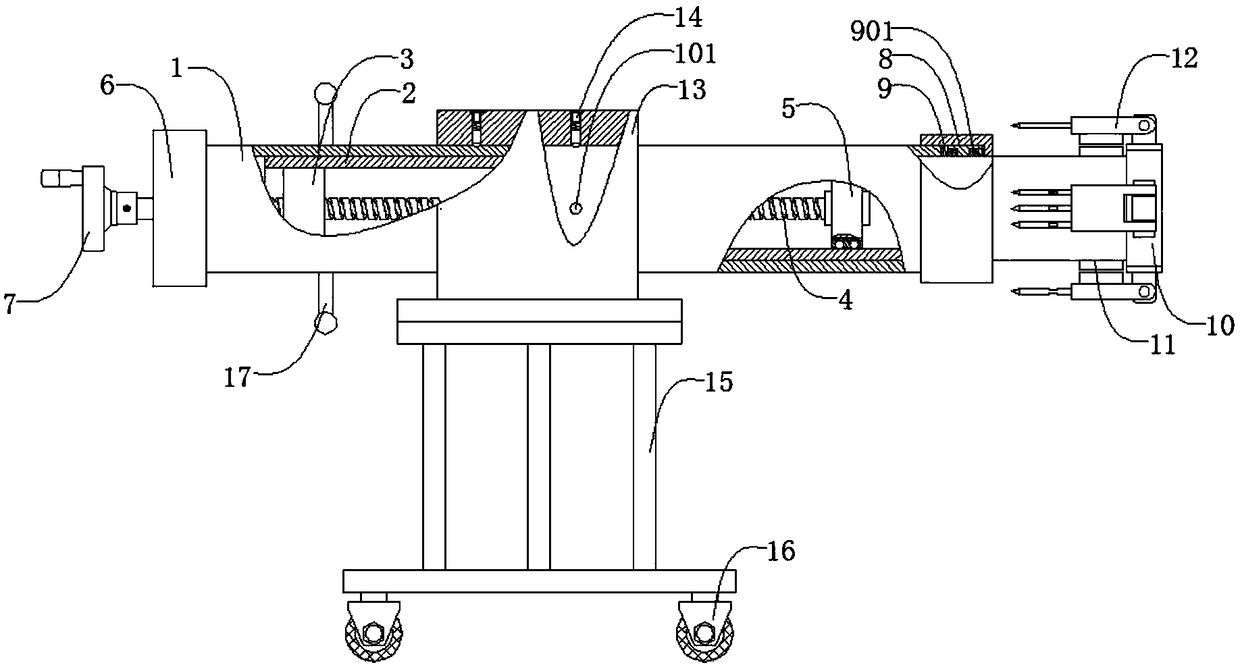

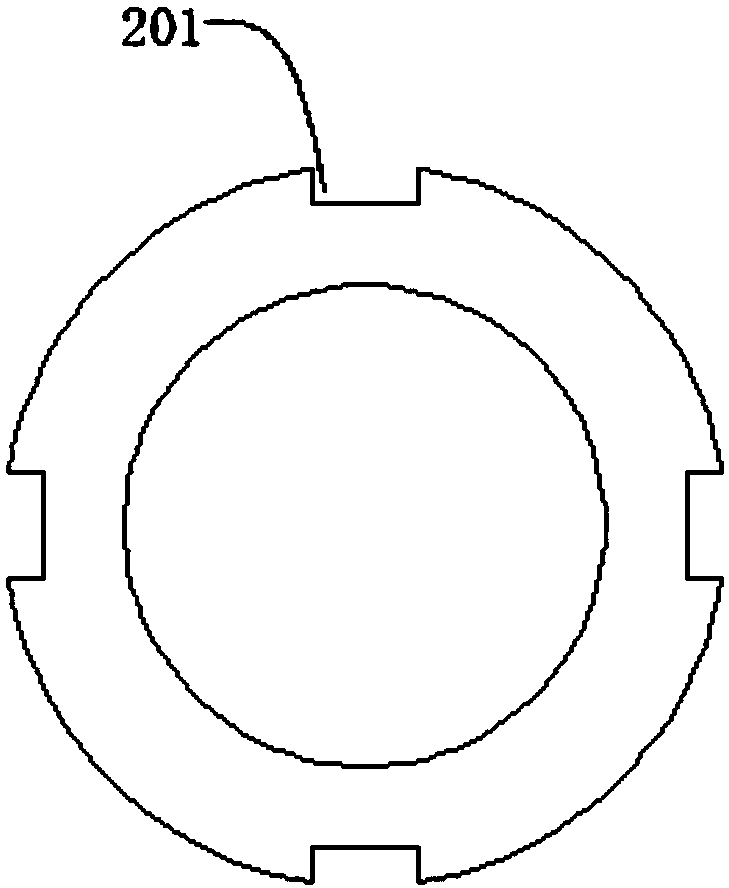

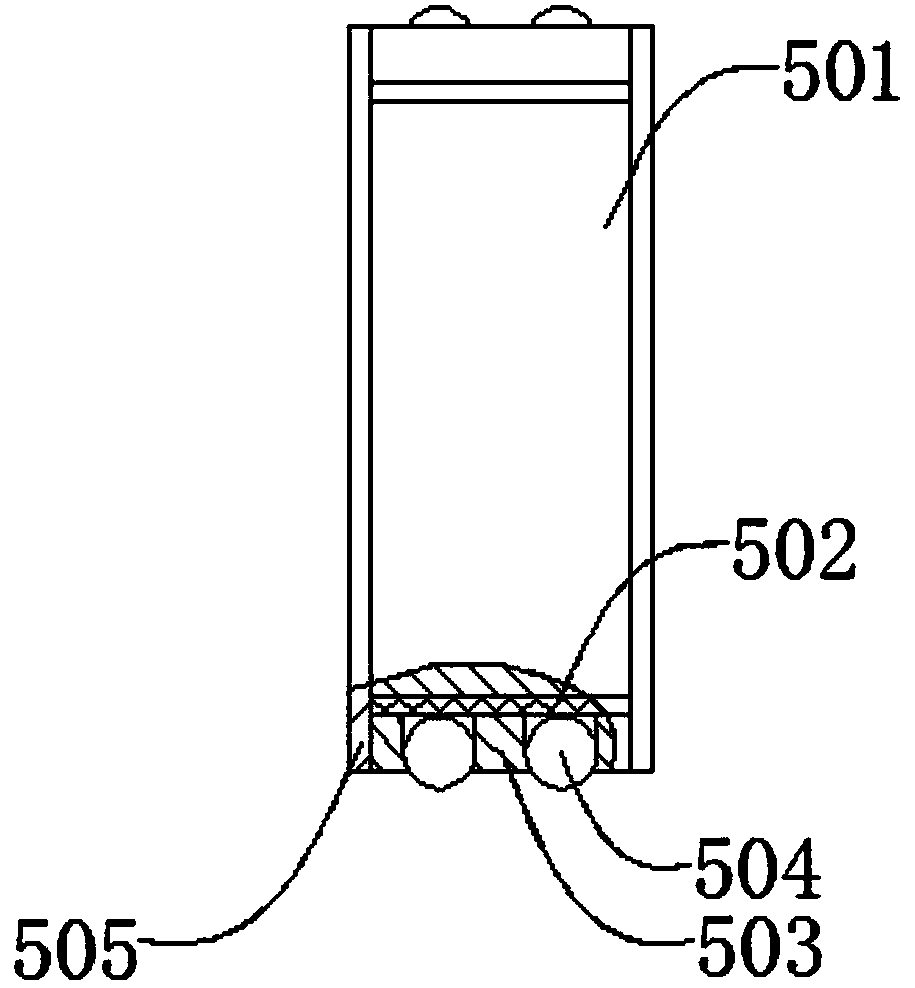

[0023] like figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Image 6As shown, a sewage pipeline cleaning device includes an outer sleeve 1, an inner sleeve 2, a feed nut 3, a screw 4, a floating support mechanism 5, an end cover 6, a hand wheel 7, a guide sleeve 8, and a sealing seat 9 , a transition plate 10, an inner magnet 11, a slag hanging mechanism 12, a support swivel seat 13, a locking mechanism 14, a bracket 15, a universal wheel 16, and a handle 17, the inner casing 2 is located inside the outer casing 1, and the The inner sleeve 2 can slide left and right along the outer sleeve 1, the feed nut 3 is located at the inner left end of the inner sleeve 2, the feed nut 3 is welded to the inner sleeve 2, and the screw 4 runs through Feed nut 3, the lead screw 4 is threadedly connected with the feed nut 3, the floating support mechanism 5 is located at the inner right end of the inner casing 2 and penetrated by the lead screw 4, the floating support mechanism...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com