Anti-icing and deicing system used for wind driven generator set and method thereof

A technology for anti-icing and fan blades, which is applied in wind turbines, wind power generation, engines, etc., can solve problems that are not conducive to the stability of anti-icing and deicing devices, so as to improve availability and power generation performance, extend service life, and be flexible sex high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

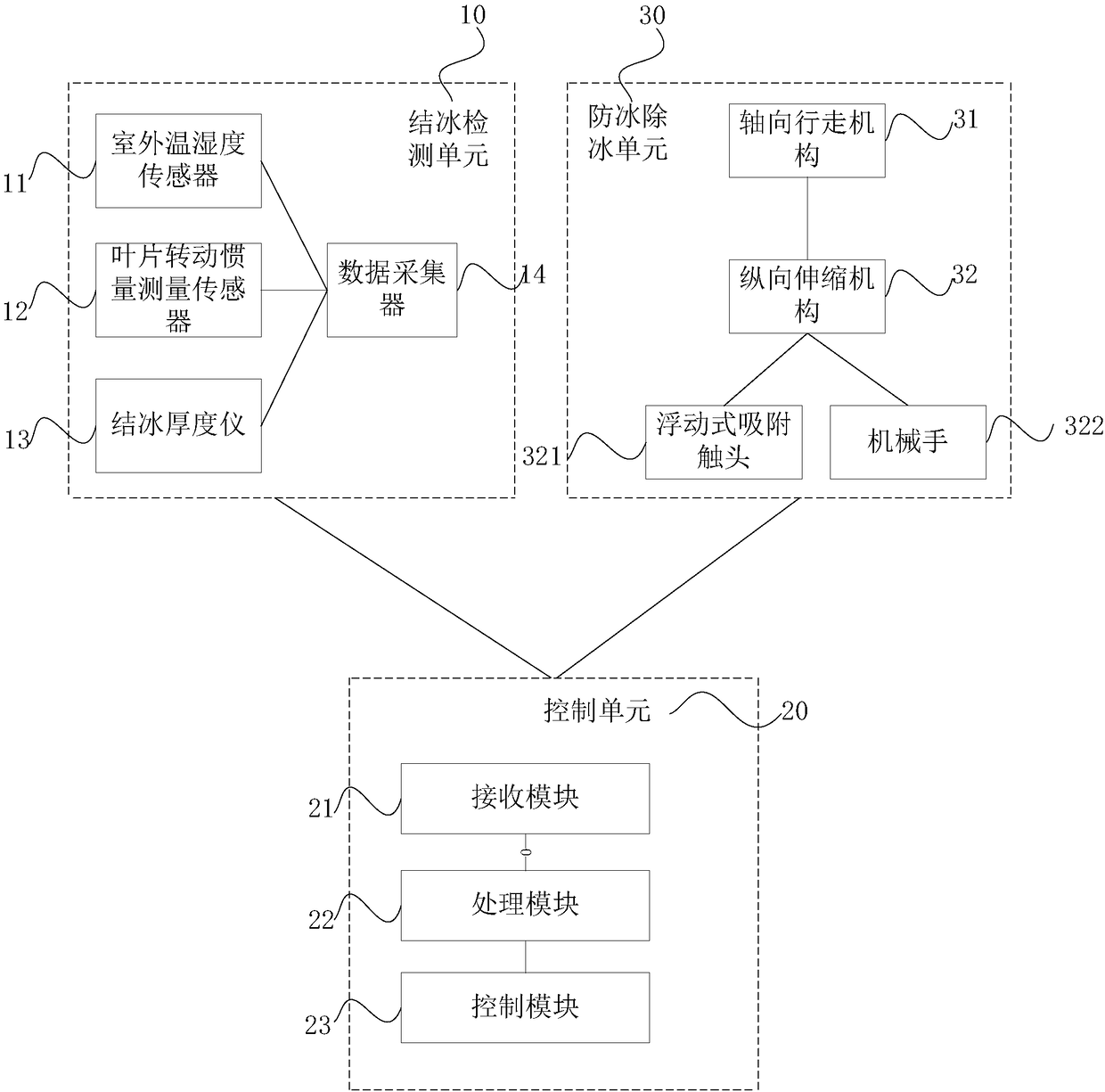

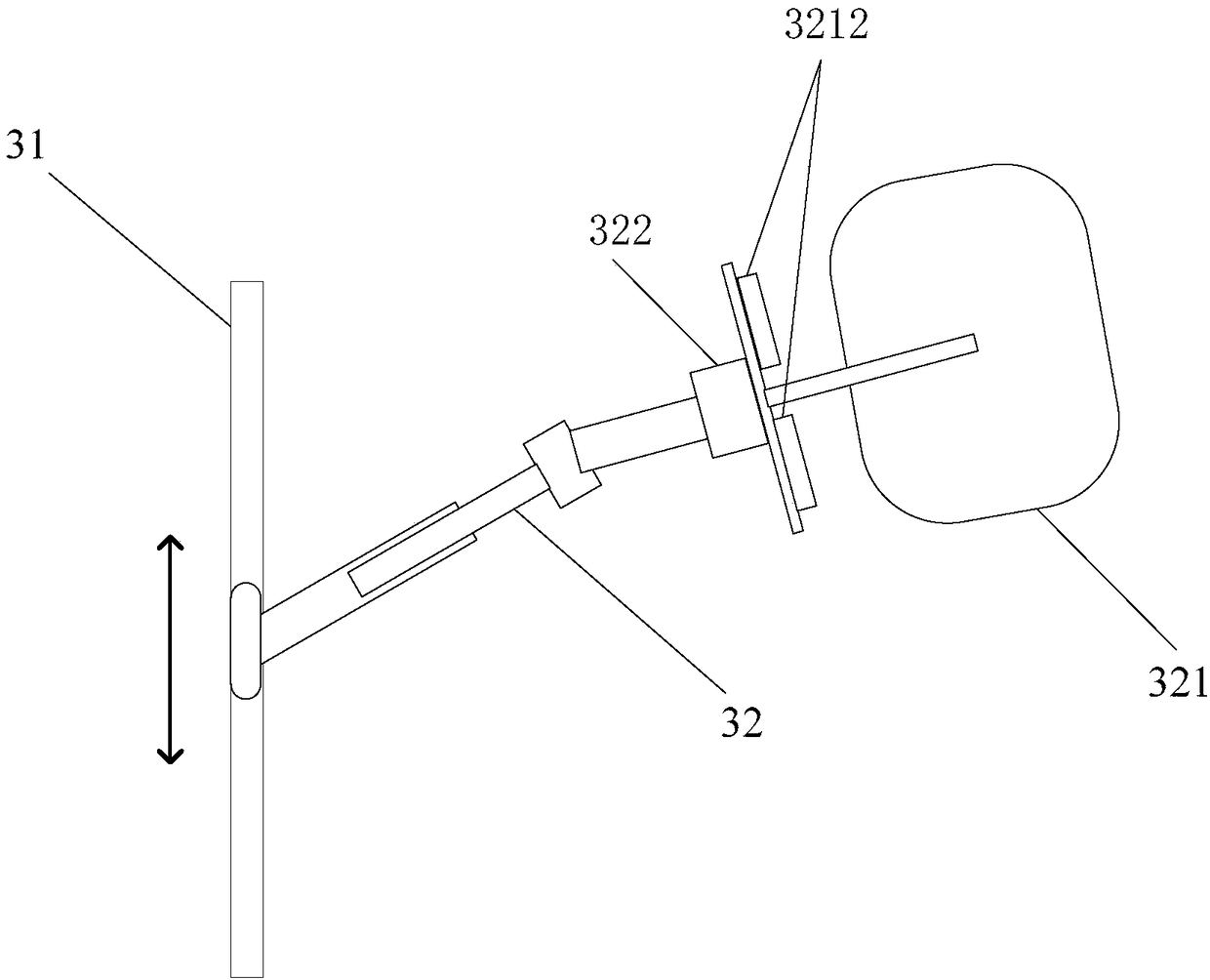

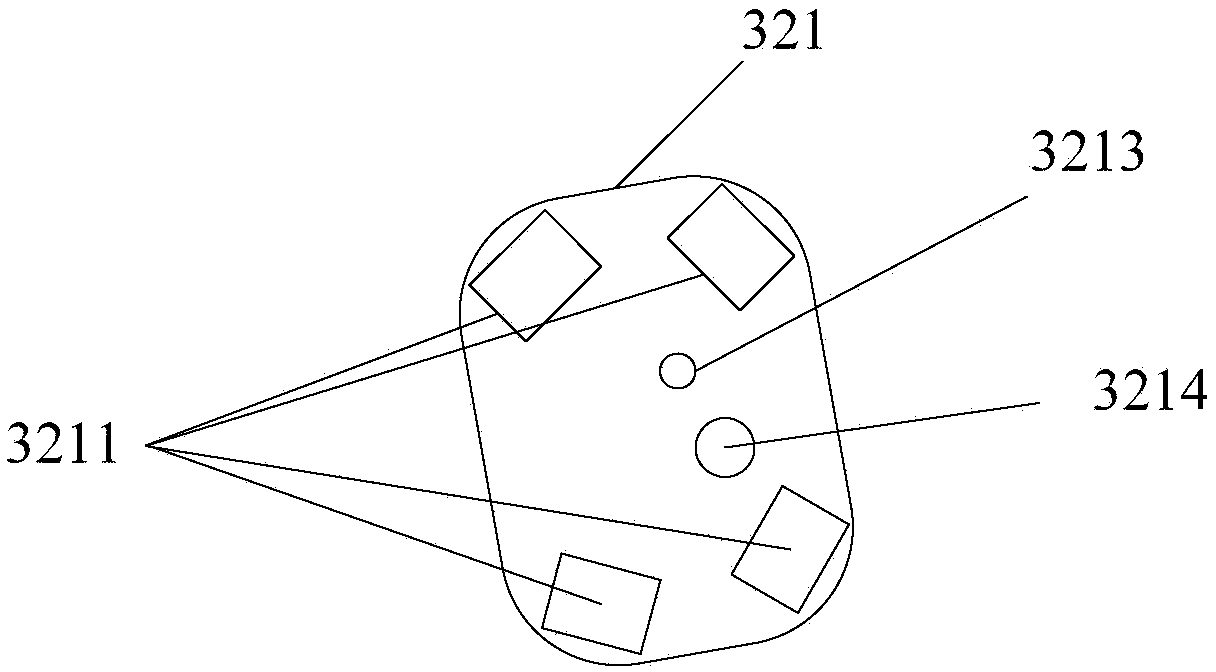

[0070] Such as Figure 1-Figure 3(b) as shown, figure 2 The schematic structural diagram of the anti-icing and deicing unit provided by the embodiment of the present invention; Fig. 3 (a) is the structural schematic diagram of the floating adsorption contact provided by the embodiment of the present invention Figure 1 ; Figure 3 (b) is a schematic structural representation of the floating suction contact provided by the embodiment of the present invention Figure II The anti-icing and deicing system for fan blades provided by the embodiment of the present invention includes an icing detection unit 10, a control unit 20 and an anti-icing and deicing unit 30, and the icing detection unit 10 and the anti-icing and deicing Unit 30 is electrically connected to said control unit 20, wherein,

[0071] The icing detection unit 10 is used to detect the icing condition of the fan blades, and send the detection data to the control unit 20;

[0072] The control unit 20 is used to rec...

Embodiment 2

[0081] In the embodiment of the present invention, the anti-icing and de-icing unit 30 further includes a plurality of sliding rails arranged in the fan blade, and the axial traveling mechanism 31 moves along the sliding rails.

[0082] By presetting multiple sliding rails in the fan blades, the axial traveling mechanism 31 can reach any position of the fan blades along different sliding rails, so as to meet the requirements of anti-icing or deicing at different positions in the fan blades, so the flexibility It is higher, and under the support of the slide rails, the anti-icing and deicing unit 30 has higher structural stability and longer service life; it should be noted that the multiple slide rails are all arranged along the length direction of the fan blade.

[0083] Further, the floating adsorption contact 321 is also provided with a vibration monitoring sensor 3213, a temperature sensor 3214 and a limit switch 3215, wherein,

[0084] The vibration monitoring sensor 3213...

Embodiment 3

[0098] Another embodiment of the present invention provides an anti-icing and de-icing method for fan blades, wherein,

[0099] Step 1, detecting the outdoor temperature, humidity, moment of inertia change and icing thickness of the fan blade;

[0100] Step 2, judging whether the outdoor environment meets the freezing condition, if so, then execute step 3, if not, then the fan operates normally;

[0101] Step 3, judging the icing thickness of the fan blade;

[0102] If the icing thickness is less than or equal to the first threshold, the fan operates normally;

[0103] If the icing thickness is greater than the first threshold, perform step 4;

[0104] Step 4, judging whether the variation of the moment of inertia is greater than a second threshold;

[0105] If it is greater than the second threshold, then control the blades of the fan to de-ice;

[0106] If not greater than the second threshold, the fan blades are controlled to perform anti-icing.

[0107] Specifically, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com