Common-optical-path laser heterodyne interference method roll angle high-precision measuring device and method

A technology of laser heterodyne interference and measuring device, applied in measuring device, using optical device, instrument, etc., can solve the problems of inaccurate measurement, measurement influence, difficulty in roll angle measurement, etc. The effect of reducing the distance difference

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be further described in detail below in conjunction with the accompanying drawings, which are explanations rather than limitations of the present invention.

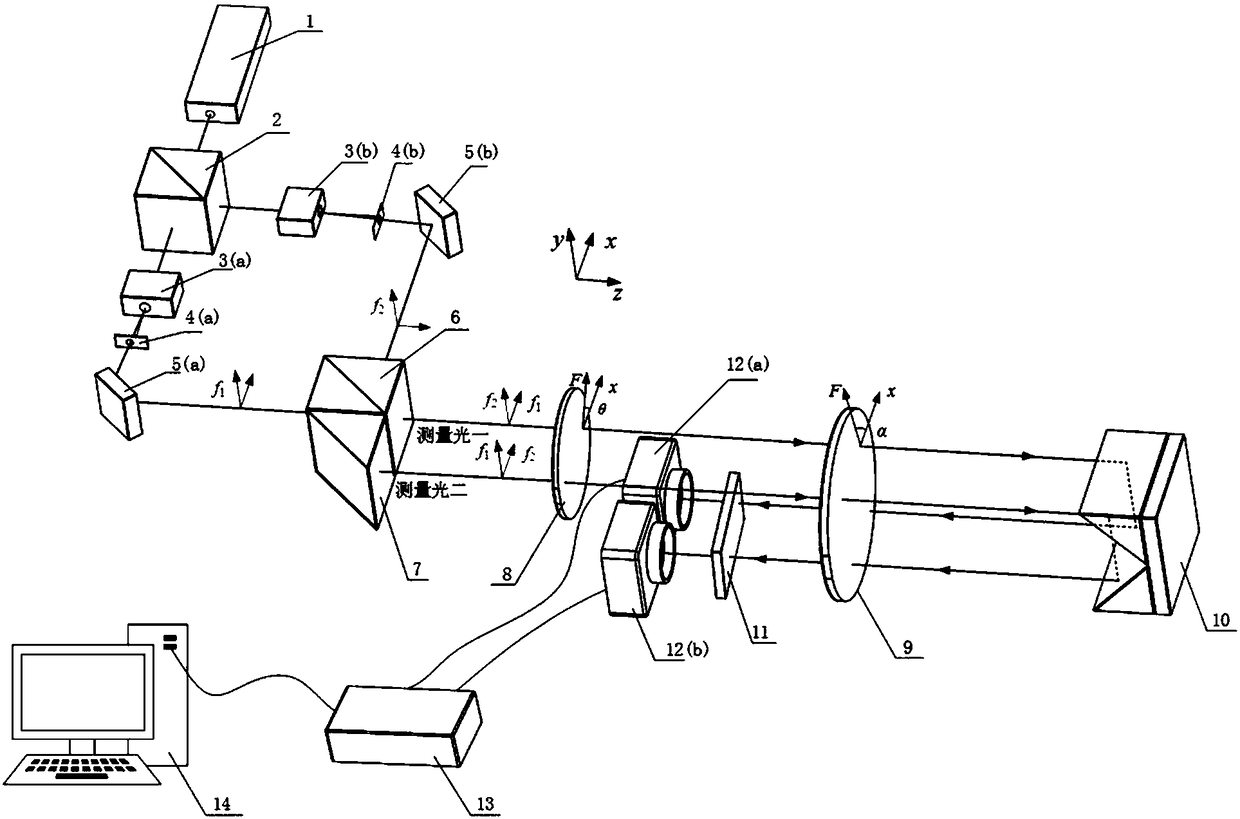

[0031] see figure 1 , a common optical path laser heterodyne interferometry roll angle high-precision measurement device, characterized in that it includes a single-frequency stabilized laser 1, a depolarization beamsplitter prism 2 arranged on the output optical path of the single-frequency stabilized laser 1, and a polarization beamsplitter prism 6 and a rectangular prism 7; the first AOM 3a and the first reflection mirror 5a are arranged in turn on the transmission optical axis of the depolarization beam splitter prism 2; the first reflection mirror 5a is used for the first AOM 3a A diffracted light is reflected to the polarization splitter prism 6; the second acousto-optic modulator 3b and the second reflection mirror 5b are sequentially arranged on the reflection axis of the depolar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com