Detector mobile-type detection device and method for bone-containing fish slices

A testing equipment and detector technology, applied in the direction of using radiation for material analysis, etc., can solve the problems of reducing the freshness of aquatic products, prolonging the processing time, and taking a long time, so as to avoid the detection of incomplete defects and reduce labor costs. , the effect of easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

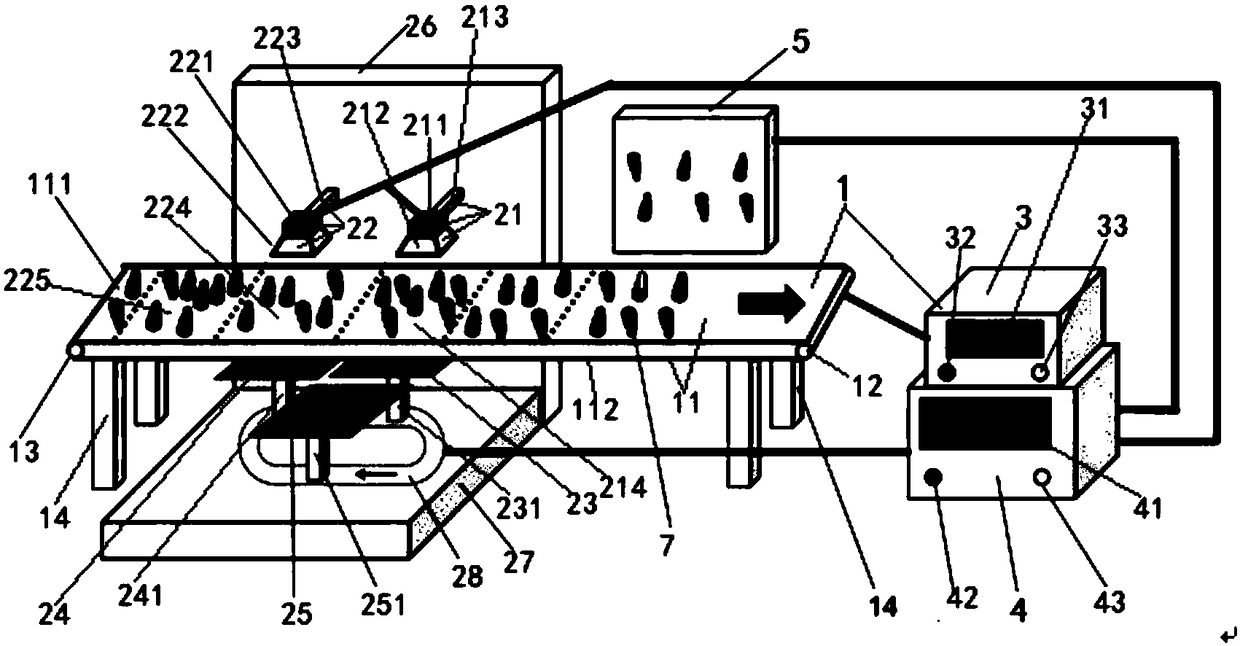

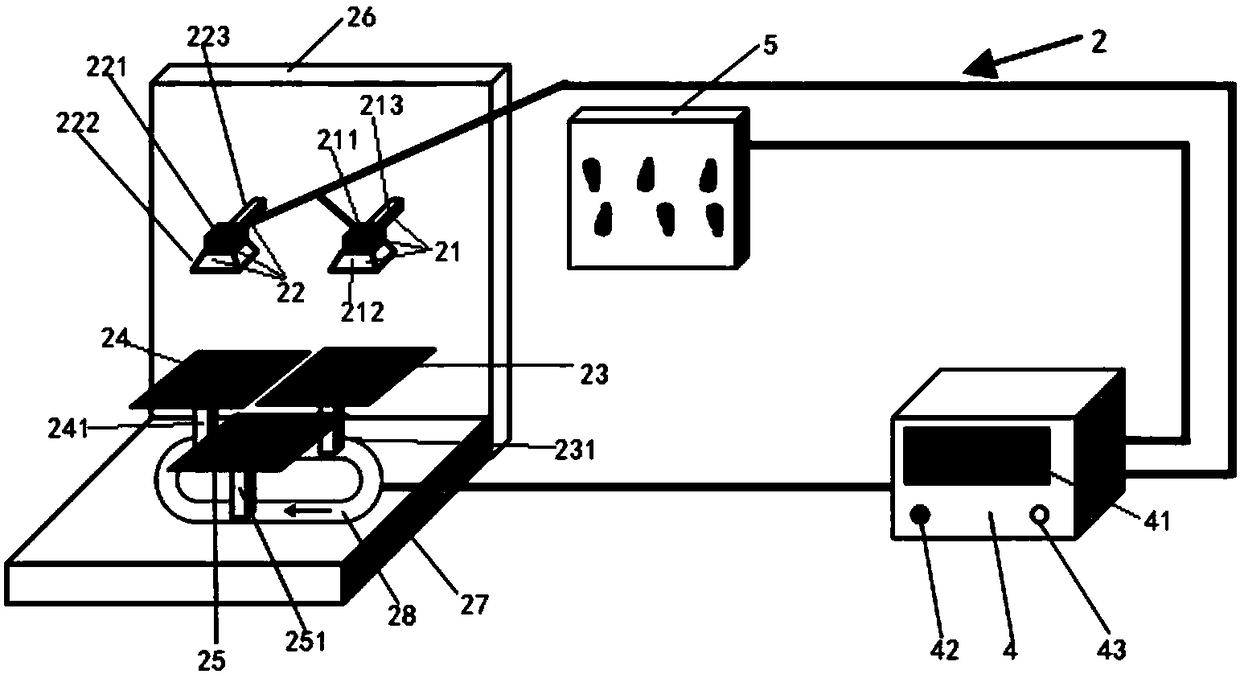

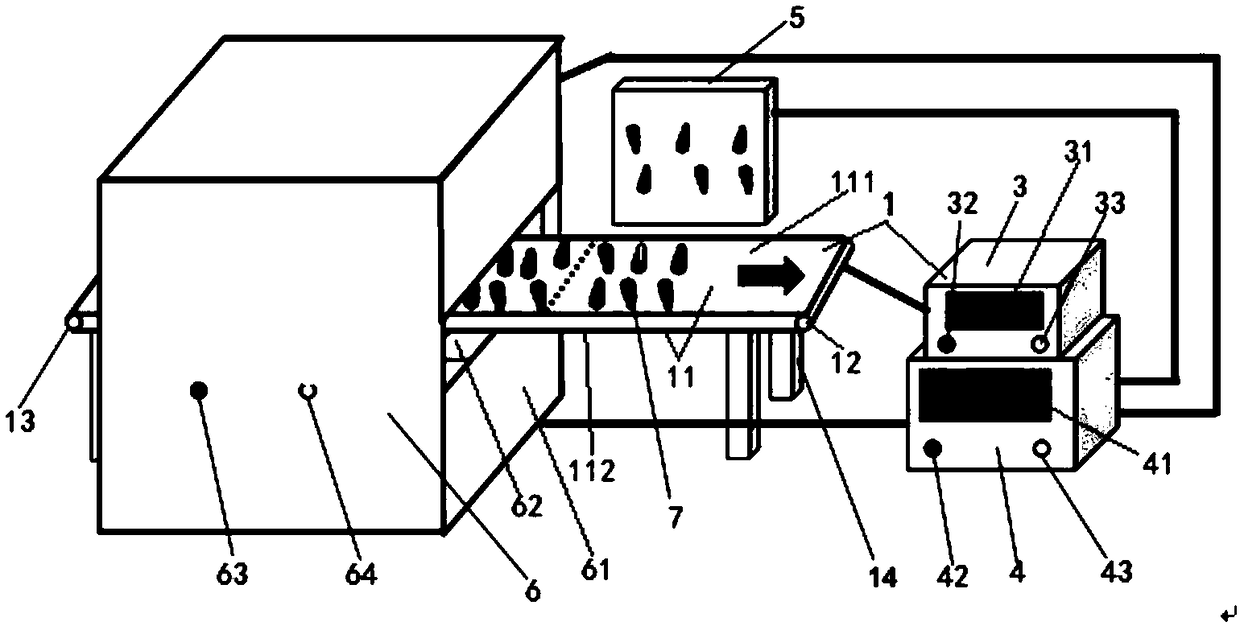

[0043] Such as figure 1 and figure 2 The shown mobile detection equipment for bone-containing fish fillets includes a conveying device 1 and an X-ray detection device 2 .

[0044] Transmission device 1 comprises conveyor belt 11, front end roller 12, rear end roller 13, transmission support 14 and transmission control device 3, and conveyor belt 11 is the closed conveyor belt that is made up of upper conveyor belt 111 and lower conveyor belt 112, front end roller 12 and rear end The rollers 13 are respectively fixed on the front and rear ends of the transmission bracket 14 and are located between the upper conveyor belt 111 and the lower conveyor belt 112 for supporting the conveyor belt 11 and driving the conveyor belt 11 to perform circular motion. Fish fillet 7 is placed on the conveyer belt 11.

[0045] The transmission control device 3 controls the operation of the front roller 12 and the rear roller 13. The transmission control device 3 includes a transmission control...

Embodiment 2

[0068] As a preferred embodiment of the present invention, the detector mobile detection equipment used in this embodiment for bone-containing fish fillets is the same as Embodiment 1, the difference is that, as figure 1 and figure 2 As shown, the shapes of the first X-ray irradiation area 214 and the second X-ray irradiation area 224 are the same; the shapes of the first X-ray receiving plate 23, the second X-ray receiving plate 24, and the third X-ray receiving plate 25 are the same, And the shapes of the first X-ray irradiation area 214 and the second X-ray irradiation area 224 are the same, and the respective lengths of the first X-ray receiving plate 23, the second X-ray receiving plate 24, and the third X-ray receiving plate 25 are equal to 1 / 3 of the length of the circular track-type receiving motion track 28 , the respective lengths of the first X-ray irradiation area 214 and the second X-ray irradiation area 224 are equal to 1 / 3 of the length of the circular track-ty...

Embodiment 3

[0073] The method for detecting fish bones in fish fillets using the above-mentioned detector mobile detection equipment for bone-containing fish fillets is as follows:

[0074] Step 1, setting the moving speed of the first X-ray receiving board 23, the moving speed of the second X-ray receiving board 24, the moving speed of the third X-ray receiving board 25 and the transmission speed of the conveyor belt 11, and the first X-ray receiving board 23, the moving speed of the second X-ray receiving plate 24, the moving speed of the third X-ray receiving plate 25 and the conveying speed of the conveyor belt 11 are all the same.

[0075] Step 2. After or when the fish fillet 7 is placed on the conveyor belt 11, open the transmission control device 3 of the conveyor 1, the fish fillet 7 enters the protective cover 6 with the conveyor belt 11, and open the detection control device 4 of the X-ray detection device 2, Control the first X-ray irradiation area 214 of the first X-ray emitt...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com