Bidirectional adjustment self-suction phased array probe scanning device and assembling and detecting method

A technology of phased array probes and scanning devices, which is applied to measuring devices, using sound waves/ultrasonic waves/infrasonic waves to analyze solids, and using sound waves/ultrasonic waves/infrasonic waves for material analysis, etc., which can solve the problem of low detection efficiency and accuracy and scanning Specific device specifications, limited scope of application and other issues, to achieve the effect of improving on-site detection efficiency, convenient disassembly and assembly, and wide application range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be specifically described below in conjunction with the accompanying drawings and embodiments.

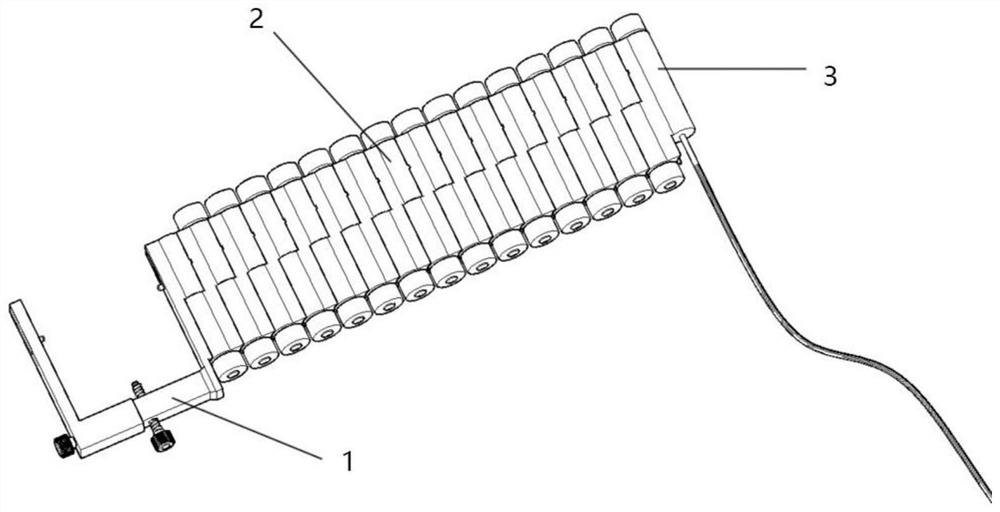

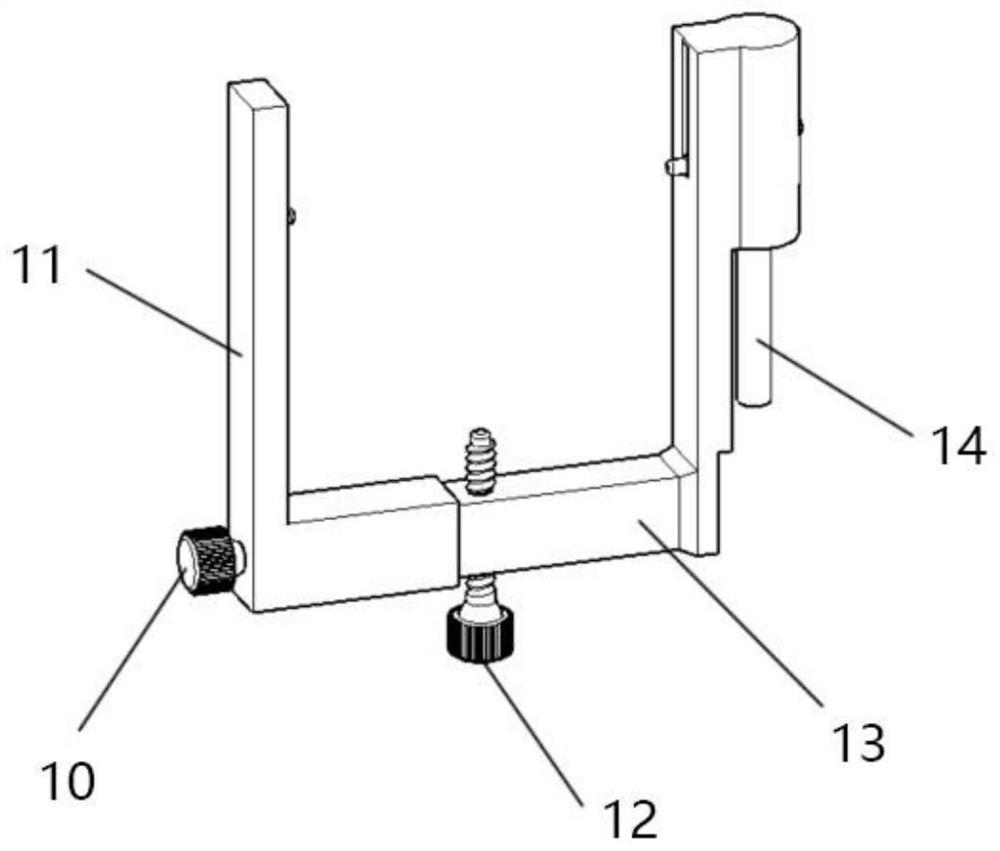

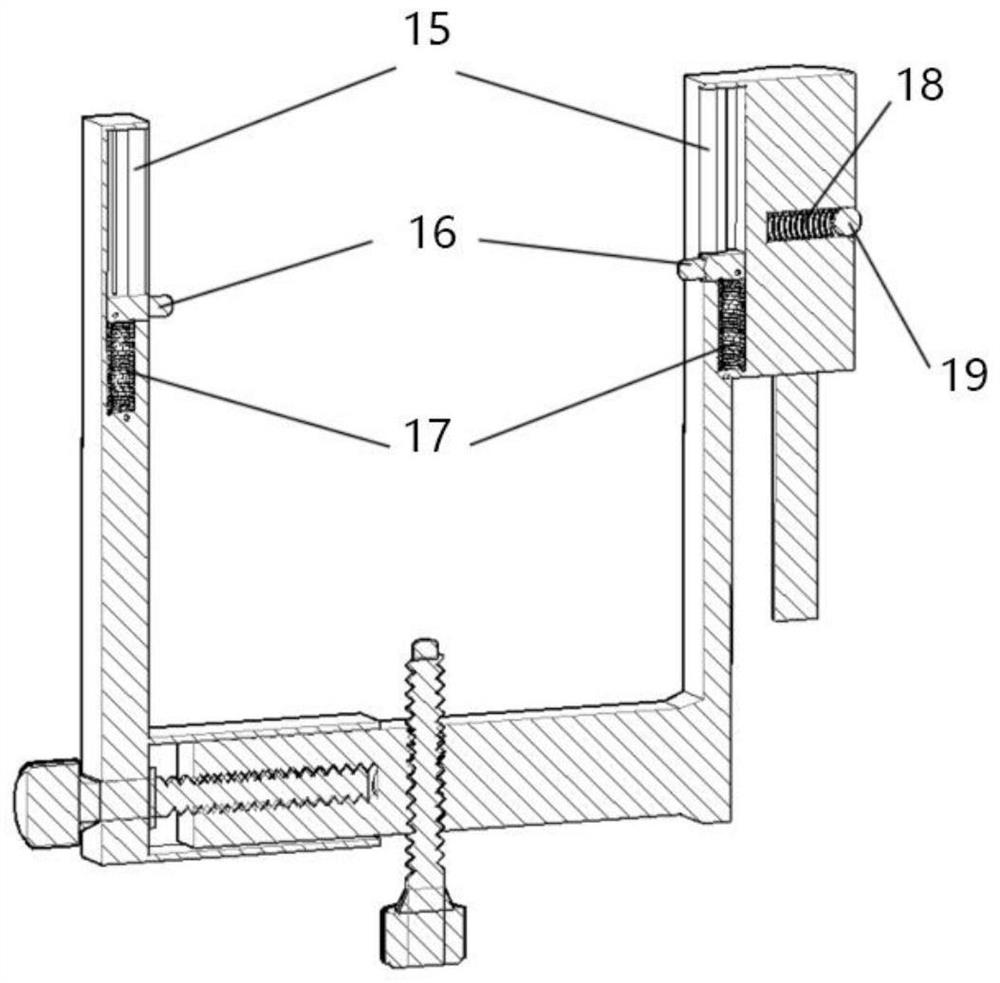

[0032] like figure 1 , figure 2 , Figure 5 , Figure 7 , Figure 8 As shown, the present invention provides a two-way adjustable self-priming phased array probe scanning device, which is a chain structure as a whole, including a probe holding device 1, a plurality of component modules 2, an encoder 3, a plurality of component The module 2 forms a scanning device chain body; the probe supporting device 1 consists of an L-shaped sliding support arm 11 and an L-shaped fixed support arm 13 to form a support device body frame, and the lower part of the sliding support arm 11 is provided with a support arm adjustment knob 10, and the sliding support arm 11 and the fixed support arm 13 are connected through the support arm adjustment knob 10; one side of the fixed support arm 13 is provided with a cylindrical positioning shaft 14, and the probe hold...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com