A silver-coated spinel-type limn 2 o 4 Composite material and its preparation method

A technology of spinel type and composite materials, which is applied in the preparation of composite materials and the field of composite materials of silver single substance coated spinel type LiMn2O4, which can solve the problems of many steps and complicated preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

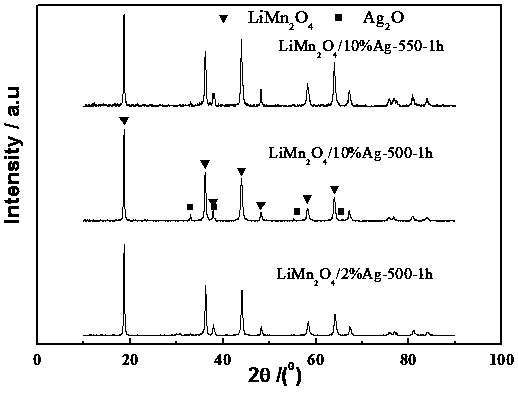

[0066] Embodiment 1: Silver single substance coated spinel LiMn of the present invention 2 o 4 preparation of composite materials.

[0067] The implementation mode of this embodiment is as follows:

[0068] A. Preparation of silver nitrate solution

[0069] Silver nitrate is dissolved in distilled water to prepare a silver nitrate solution with a concentration of 0.8% by weight;

[0070] B. Preparation of precursor

[0071] Spinel-type LiMn sold under the trade name lithium manganate by Beijing Huoke Technology Co., Ltd. 2 o 4 , mix well with glucose according to the weight ratio of 10:0.8, and then add the mixture to the silver nitrate solution obtained in step B, wherein LiMn 2 o 4 The weight ratio of silver to silver nitrate is 1:0.02, using a stirrer at a speed of 30rpm to stir and mix for 2.2h to make spinel LiMn 2 o 4 Disperse evenly to obtain a slurry mixture, and then heat in a drying oven at a temperature of 105° C. for 1.0 h to evaporate and remove moisture ...

Embodiment 2

[0075] Embodiment 2: Silver single substance coated spinel LiMn of the present invention 2 o 4 preparation of composite materials.

[0076] The implementation mode of this embodiment is as follows:

[0077] A. Preparation of silver nitrate solution

[0078] Silver nitrate is dissolved in distilled water to prepare a silver nitrate solution with a concentration of 0.5% by weight;

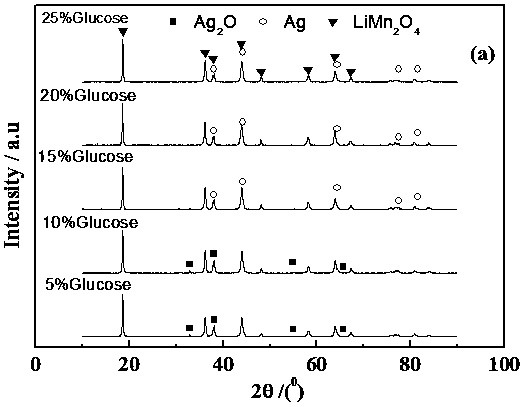

[0079] B. Preparation of precursor

[0080] Spinel-type LiMn prepared according to the method of Jintao Liu et al. (Solid State Ionics, 2017, 307:79–89) 2 o 4 Mix evenly with glucose at a weight ratio of 10:0.5, and then add the mixture to the silver nitrate solution obtained in step B, wherein LiMn 2 o 4 The weight ratio of silver to silver nitrate is 1:0.10, using a stirrer at a speed of 50rpm to stir and mix for 1.8h to make spinel LiMn 2 o 4 Disperse evenly to obtain a slurry mixture, and then heat in a drying oven at a temperature of 105° C. for 2.0 h to evaporate and remove moisture to...

Embodiment 3

[0084] Embodiment 3: Silver single substance coated spinel LiMn of the present invention 2 o 4 preparation of composite materials.

[0085] The implementation mode of this embodiment is as follows:

[0086] A. Preparation of silver nitrate solution

[0087] Silver nitrate is dissolved in distilled water to prepare a silver nitrate solution with a concentration of 1.4% by weight;

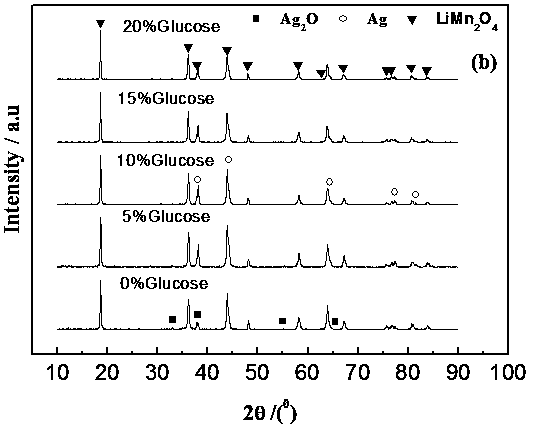

[0088] B. Preparation of precursor

[0089] Spinel-type LiMn sold under the trade name lithium manganate by Beijing Huoke Technology Co., Ltd. 2 o 4 Mix evenly with glucose at a weight ratio of 10:0.6, and then add the mixture to the silver nitrate solution obtained in step B, wherein LiMn 2 o 4 The weight ratio of silver to silver nitrate is 1:0.06, using a mixer at a speed of 60rpm to stir and mix for 2.0h to make spinel LiMn 2 o 4 Disperse evenly to obtain a slurry mixture, and then heat it in a drying oven at a temperature of 105°C for 1.6 h to evaporate and remove moisture to obtain a p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com