Jerky stoving device

A drying device and beef jerky technology, which is applied in drying, drying machines, heating devices, etc., can solve the problems of unreasonable heating tube setting and uneven heating of beef, and achieve uniform roasting effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] Further detailed explanation through specific implementation mode below:

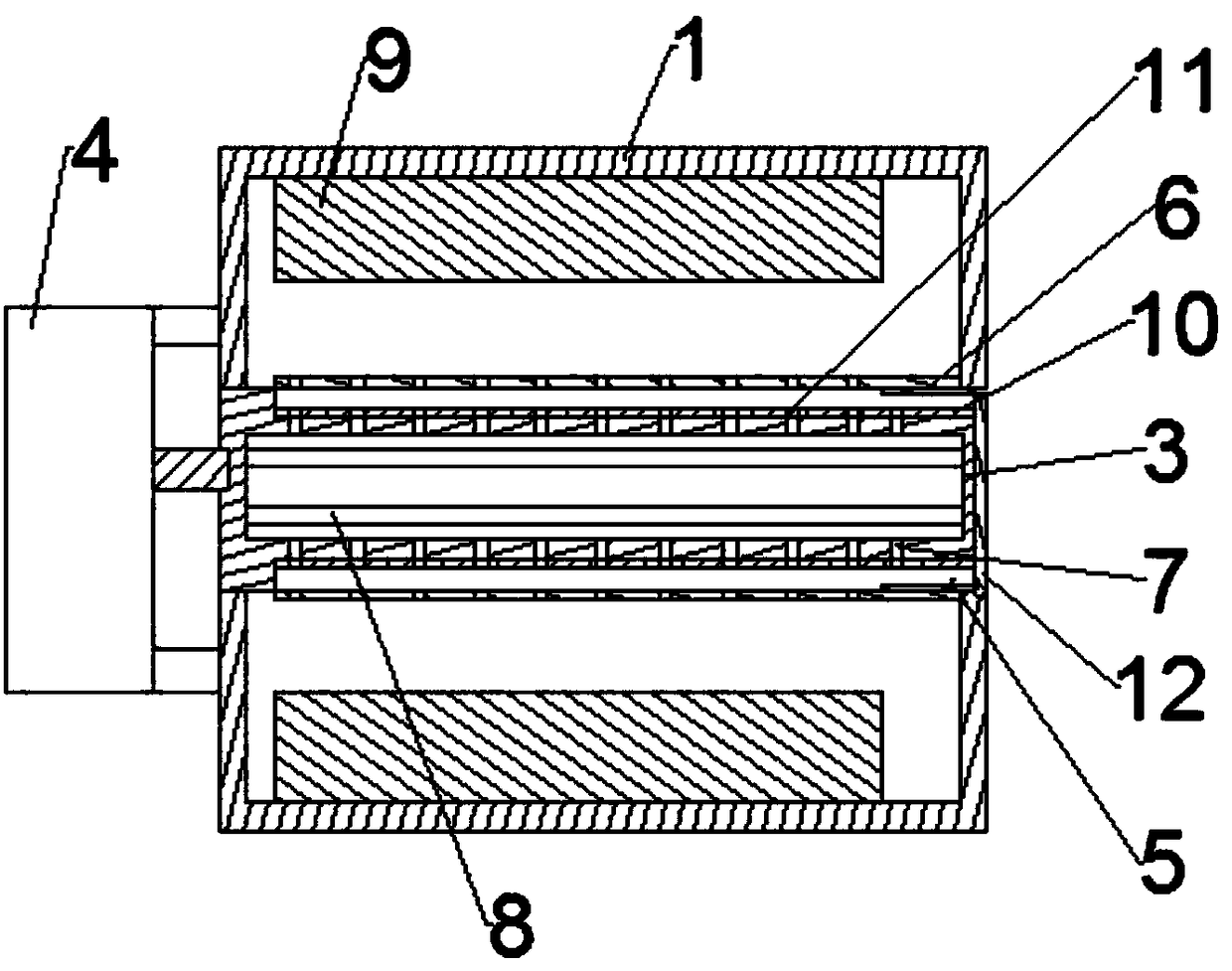

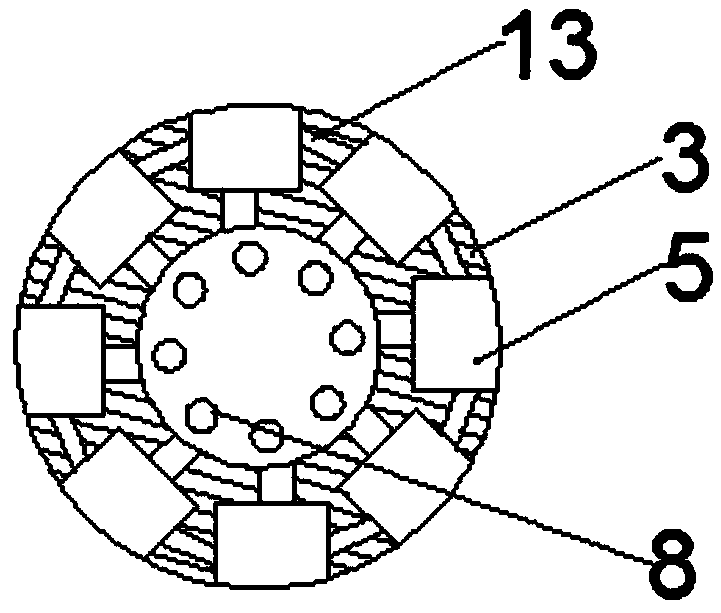

[0016] The reference signs in the drawings of the description include: box body 1, revolving door 2, drum 3, motor 4, groove 5, screen 6, through hole 7, heating pipe 8, heating plate 9, tray 10, cooling hole 11 , door body 12, ventilation hole 13.

[0017] The embodiment is basically as attached figure 1 , attached figure 2 And attached image 3 Shown: a beef jerky drying device, including a box body 1 with a revolving door 2, a hollow drum 3 is connected to the horizontal rotation of the box body 1, and a motor 4 is connected to one end of the drum 3 to drive its rotation. The circumferential surface of the cylinder 3 is provided with some grooves 5 for placing beef, and the groove 5 is slidably connected with a screen 6 for fixing the beef. The bottom of the groove 5 is connected, and the inner ring of the drum 3 is provided with a number of heating pipes 8. The top and bottom of the drum...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com