Piston machining process

A processing technology and piston technology, which is applied in the field of piston processing technology, can solve the problems of difficult control of processing precision, complicated processing procedures, high processing cost, etc., and achieve the effects of high processing precision, improved production efficiency and good wear resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

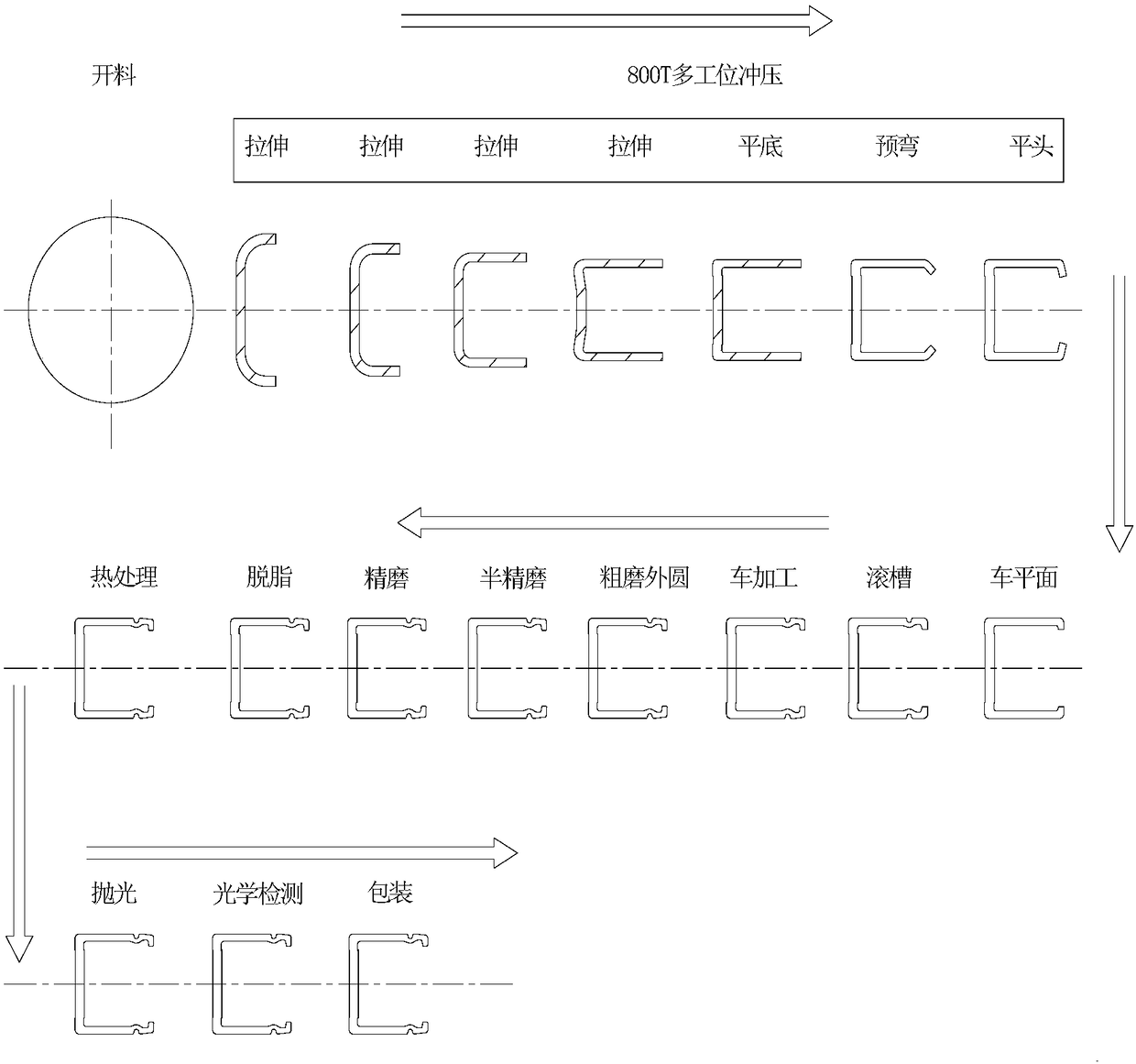

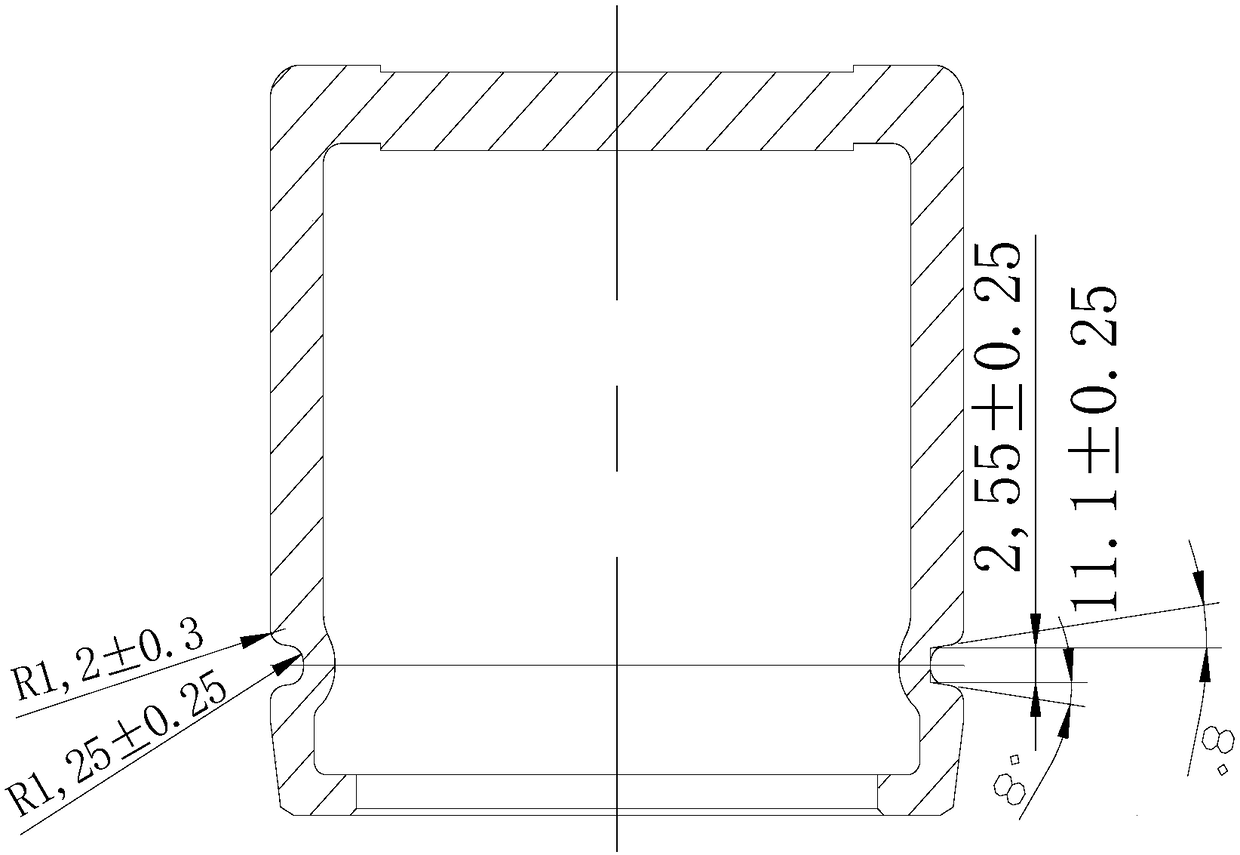

[0034] Embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

[0035] refer to Figure 1 to Figure 2 , the present invention provides a kind of piston processing technology, it comprises the following steps: a, cut material, select the material of SPHE to carry out blanking treatment, the size after blanking is that diameter is greater than or equal to 115.8mm, and is less than or equal to 116.2mm, and thickness is 6mm The cylinder, the punch selected for cutting is 120T; b, stretching, the blank is stretched for the first stretch, the second stretch, the third stretch, the fourth stretch, the first stretch After the outer diameter is 77mm, the inner diameter is greater than or equal to 64.7mm and less than or equal to 65.3mm, the height is greater than 46mm and less than 47.5mm, the fillet at the bottom is R30mm; after the second stretch, the outer diameter is 65mm, and the inner diameter is greater than or equal...

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface roughness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com