Diesel engine piston head and numerical control machining process thereof

A processing technology and piston head technology, which is applied in the field of diesel engine piston head and its numerical control processing technology, can solve the problems of numerous piston head processing procedures, affecting enterprise benefits, and high processing costs, so as to improve efficiency and work stability, and improve processing The efficiency and the effect of reducing drag

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

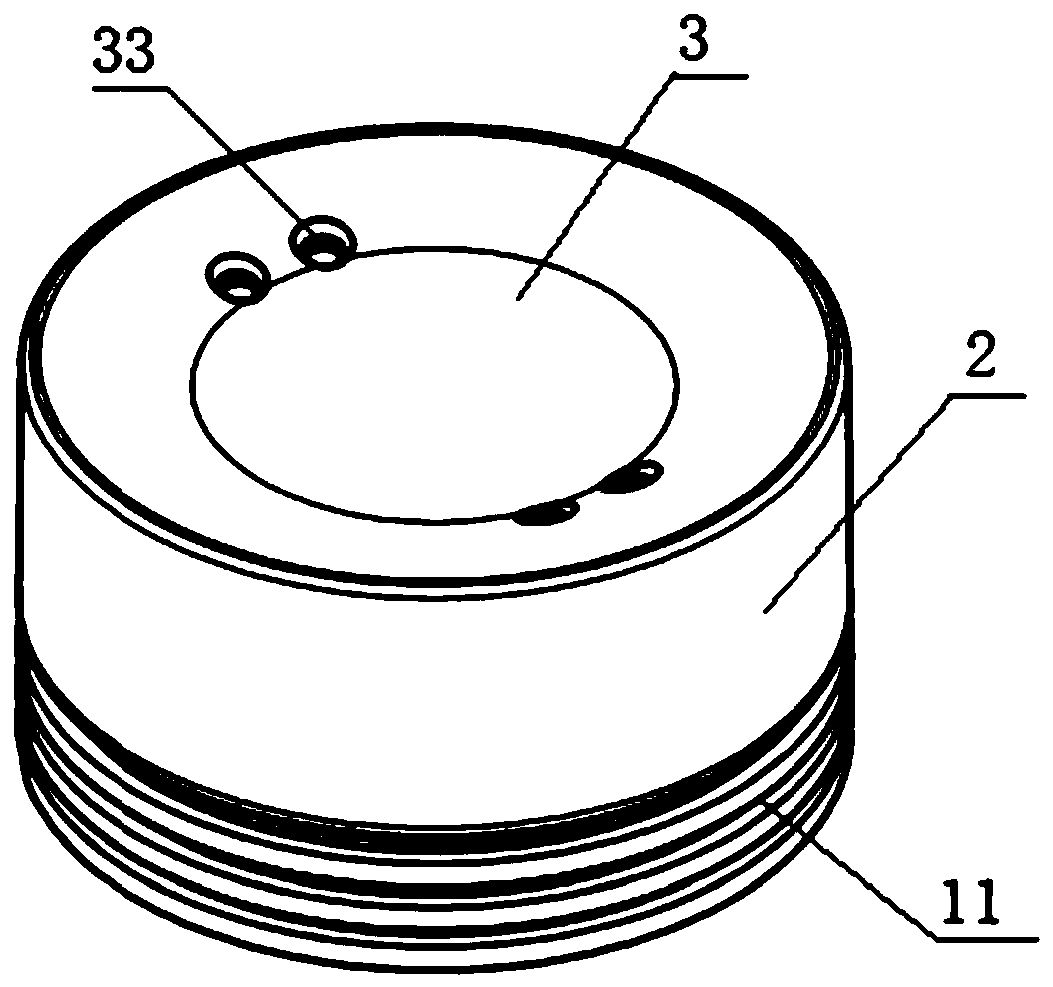

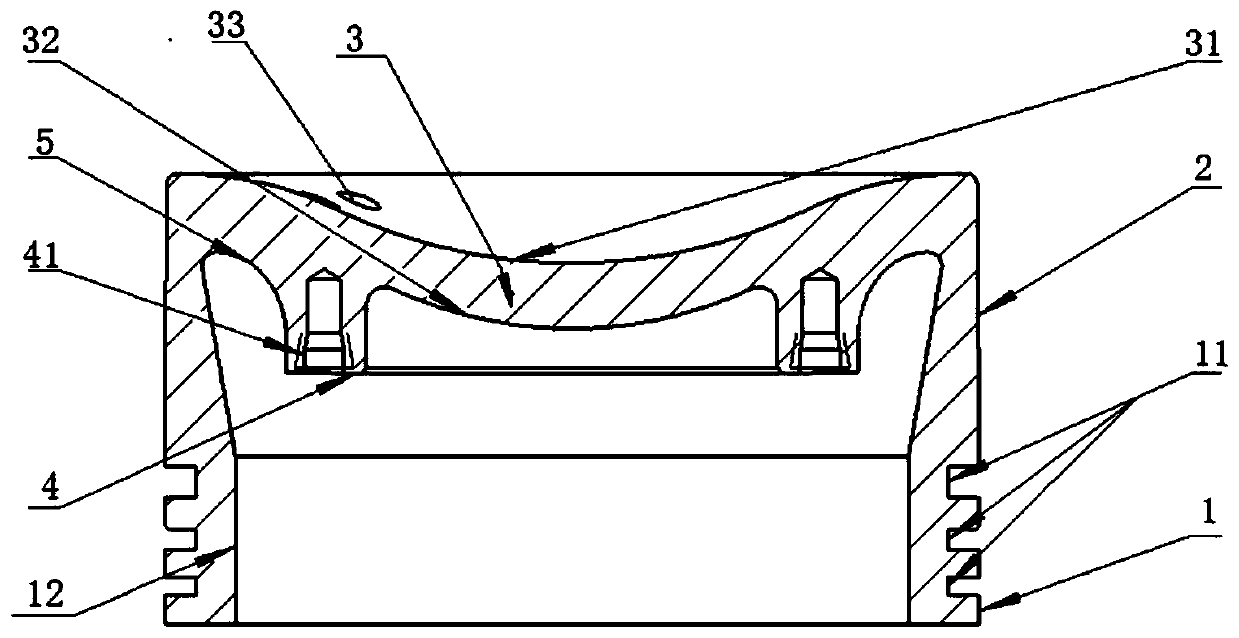

[0035] A diesel engine piston head, such as Figure 1~2 As shown, it consists of a thin-walled tube and a top 3 arranged at the top of the thin-walled tube. The upper end surface 31 of the top is in a concave arc shape. The thin-walled tube is composed of a ring groove tube 1 and a tapered tube 2 arranged one above the other. , The ring groove cylinder 1 is cylindrical with the same outer diameter (that is, the distance from the outer wall of the ring groove cylinder 1 to the central axis of the piston head is equal), with multiple ring grooves 11, the outer diameter of the tapered cylinder 2 from bottom to top Gradually become smaller. The top of the piston head is an integral part of the combustion chamber. By setting it as a concave, it is beneficial to the formation and combustion of combustible mixed gas. The concave can also be used to adjust the compression ratio of the internal combustion engine.

[0036] In this embodiment, the ring groove 11 is provided with three chan...

Embodiment 2

[0040] A numerical control machining process for a piston head of a diesel engine is used for machining the piston head of a diesel engine of Example 1. Preferably, the machining process is processed by a five-axis linkage turning center, and includes the following steps:

[0041] S1: Use the three-jaw chuck to clamp the outer circle of the blank, and use the outer turning tool to process the outer surface and top end surface of the thin-walled cylinder through rough turning and finishing. In this embodiment, the outer turning tool is used Rough turning and finishing turning the outer circle and end face with a diameter of 348.4mm;

[0042] S2: Use the inner turning tool to process the inner surface of the ring groove cylinder, the inner surface of the tapered cylinder, the inner circle of the inner cavity boss and the lower end surface of the inner cavity boss through rough turning and finishing turning. In this embodiment, use Internal turning tool for rough turning and finishing...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Outer diameter | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com