Fully-rotary ROV load bearing device

A load-bearing device, full rotation technology, applied in transportation and packaging, underwater operation equipment, ships, etc., can solve the problem of unresolved ROV bow turning flexibility umbilical cable torsion safety, affecting ROV bow turning flexibility, umbilical cable obstruction Turning the bow movement and other issues to achieve the effect of improving underwater detection and operation efficiency, avoiding the reduction of electrical insulation, and improving maneuverability and flexibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The specific implementation manner of the present invention will be described below in conjunction with the accompanying drawings.

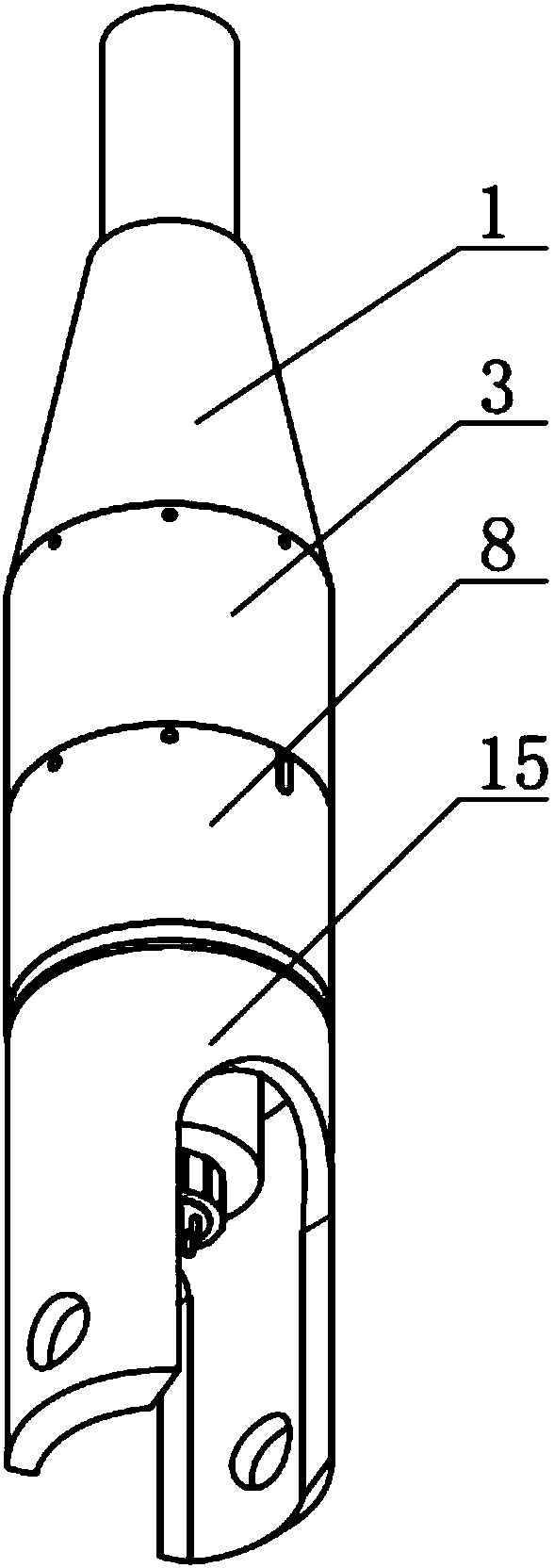

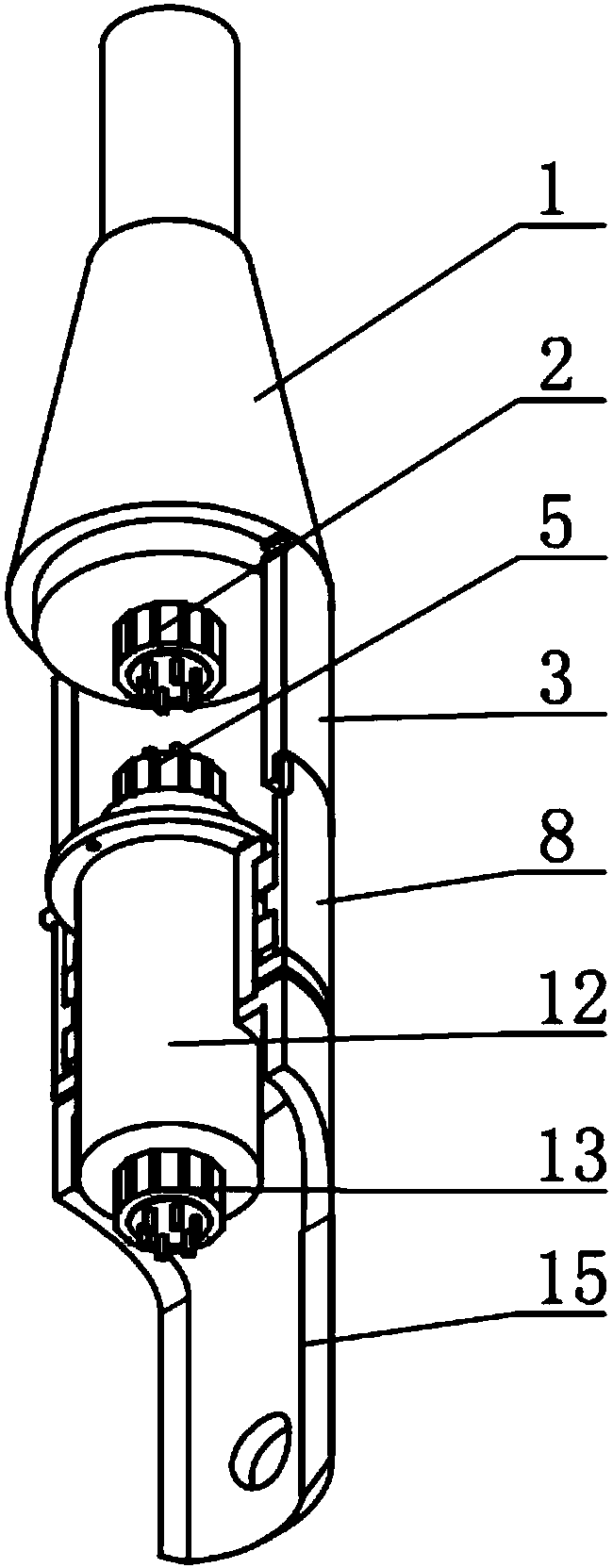

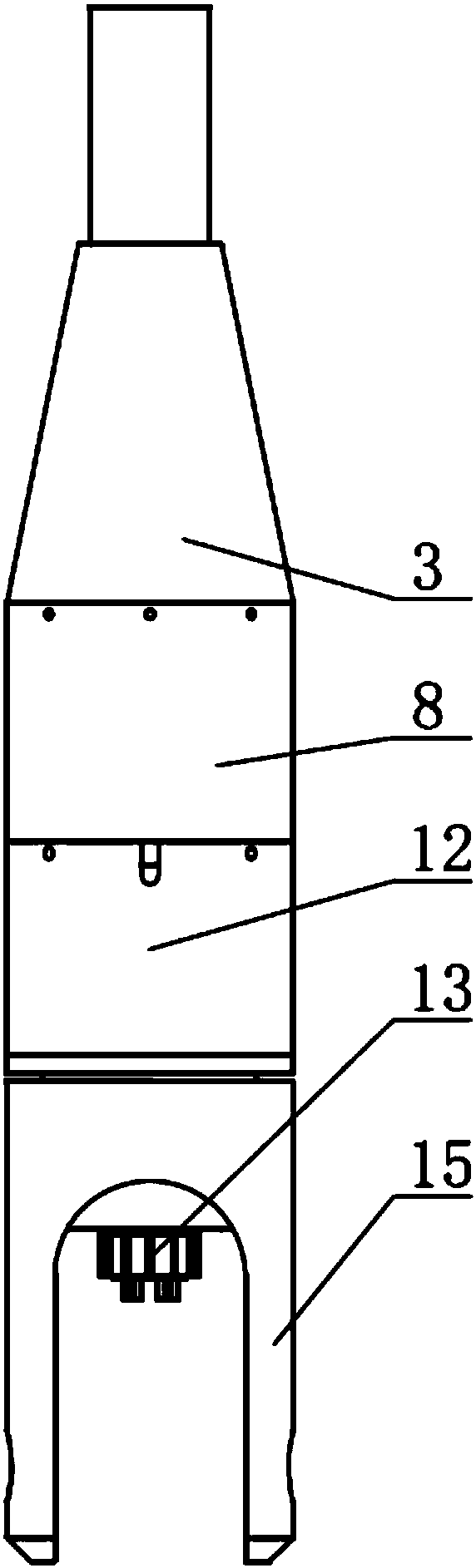

[0022] Such as figure 1 , figure 2 , image 3 and Figure 4 As shown, the full-rotation ROV load-bearing device of this embodiment includes an umbilical cable terminal 1, and the bottom of the umbilical cable terminal 1 is connected to the wiring cabin 3 through first bolt assemblies 21 uniformly distributed along the circumferential direction. In the wiring cabin 3, the umbilical cable terminal The umbilical cable watertight connector 2 of 1 is connected to the static ring watertight connector 5 through the watertight cable assembly 4; the bottom of the junction compartment 3 is fixedly installed with the slip ring compartment 8 through the second bolt assembly 20 evenly distributed along the circumferential direction, and the slip ring compartment 8 The photoelectric slip ring static ring 6 is installed on the inner wall through the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com