Protein sludge deep dehydration method

A deep dehydration and sludge technology, applied in water/sludge/sewage treatment, sludge treatment, chemical instruments and methods, etc., can solve problems such as difficult dehydration, secondary pollution, high viscosity, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

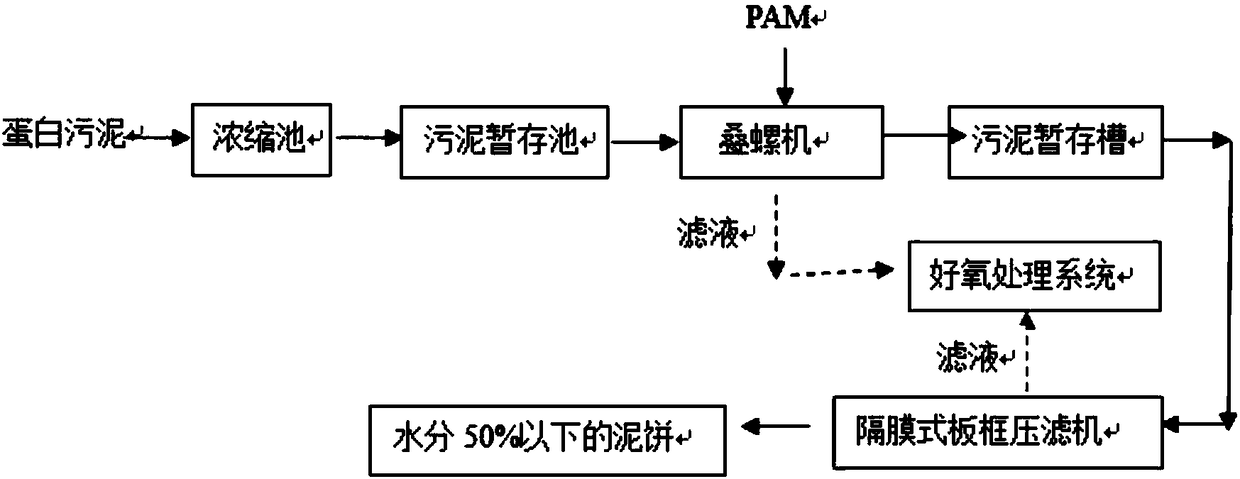

Image

Examples

Embodiment 1

[0027] A method for deep dehydration of protein sludge, comprising the steps of:

[0028] Step 1: Pump the protein sludge with a water content of 98% to the sludge concentration tank for sludge concentration, and the water content will be reduced from 98% to 95%;

[0029] Step 2: The concentrated protein sludge flows into the temporary sludge storage tank by itself;

[0030] Step 3: Use the sludge pump to transport the protein sludge in the temporary storage tank to the pipeline mixer and mix it with 0.2% cationic polyacrylamide with a weight average molecular weight of 11 million, and then enter the screw stacker for dehydration, and the water content will drop from 95% to 85% %;

[0031] Step 4: The protein sludge from the screw stacker falls into the sludge temporary storage tank by itself;

[0032] Step 5: Use the sludge pump to send the protein sludge in the sludge temporary storage tank to the diaphragm plate and frame filter press for dehydration, and the water conten...

Embodiment 2

[0035] A method for deep dehydration of protein sludge, comprising the steps of:

[0036] Step 1: Pump the protein sludge with a water content of 99% to the sludge concentration tank for sludge concentration, and the water content will be reduced from 99% to 95%;

[0037] Step 2: The concentrated protein sludge flows into the temporary sludge storage tank by itself;

[0038] Step 3: Use the sludge pump to transport the protein sludge in the temporary storage tank to the pipeline mixer and mix it with 0.1% cationic polyacrylamide with a weight average molecular weight of 12 million, and then enter the screw stacker for dehydration, and the water content will drop from 95% to 85% %;

[0039] Step 4: The protein sludge from the screw stacker falls into the sludge temporary storage tank by itself;

[0040] Step 5: Use the sludge pump to send the protein sludge in the sludge temporary storage tank to the diaphragm plate and frame filter press for dehydration, and the water conten...

Embodiment 3

[0042] A method for deep dehydration of protein sludge, comprising the steps of:

[0043] Step 1: Pump the protein sludge with a water content of 98.5% to the sludge concentration tank for sludge concentration, and the water content is reduced from 98.5% to 94%;

[0044] Step 2: The concentrated protein sludge flows into the temporary sludge storage tank by itself;

[0045] Step 3: Use the sludge pump to transport the protein sludge in the temporary storage tank to the pipeline mixer and mix it with 0.3% cationic polyacrylamide with a weight average molecular weight of 9 million, and then enter the screw stacker for dehydration, and the water content will drop from 94% to 80% %;

[0046] Step 4: The protein sludge from the screw stacker falls into the sludge temporary storage tank by itself;

[0047] Step 5: Use the sludge pump to send the protein sludge in the sludge temporary storage tank to the diaphragm plate and frame filter press for dehydration, and the water content ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com