High-strength recycled cementing material product preparation method

A technology for regenerating cementitious materials and products, applied in cement production, etc., can solve the problems of low strength and large difference in hydration activity, etc., and achieve the effects of high utilization rate, short maintenance period, good mechanical properties and volume stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

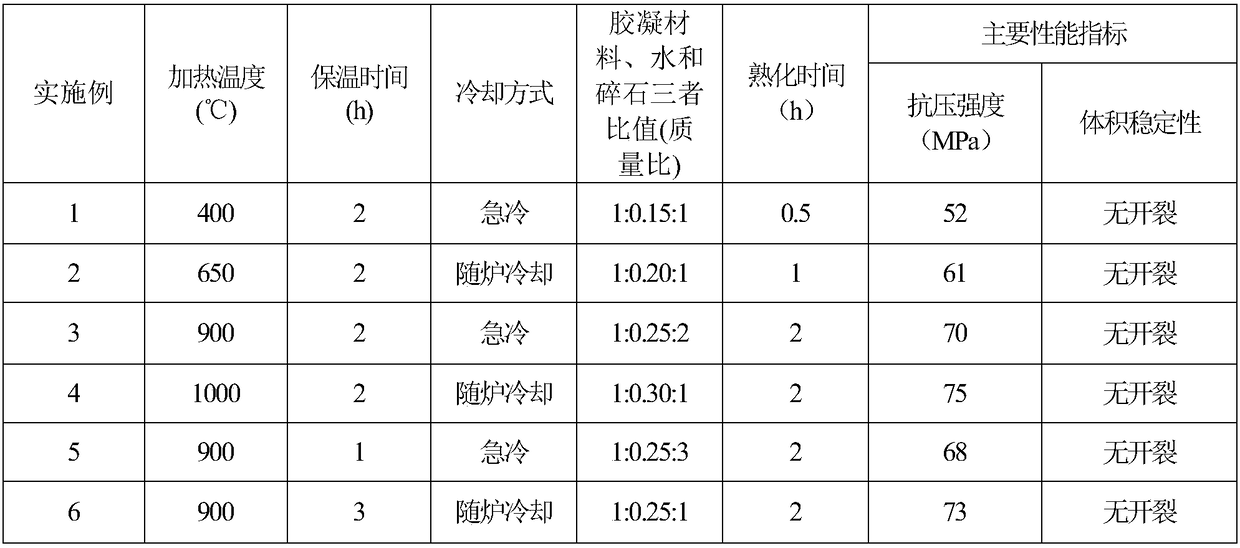

Embodiment 1-6

[0020] 1) The waste concrete is crushed, separated and ground to obtain waste cement stone powder, and the waste cement stone powder obtained by the crushing, separation and grinding is passed through an 80 μm square-hole sieve with no more than 10%. ;

[0021] 2) Heat the waste cement stone powder to 400-1000°C, keep it at the highest temperature for 1-3h, and then quench it or cool it naturally with the furnace to room temperature to obtain a recycled cementitious material;

[0022] 3) Add water to mature the cementitious material for 0.5-2h, add sand and gravel and the remaining water to mix evenly at the same time or after aging, then press to shape, and finally carbonize to obtain recycled cementitious material products; among them, recycled cementitious materials, water and sand The mass ratio of the three is 1:0.15-0.30:1-3; the carbonization condition is: CO 2 The concentration is not less than 99%, CO 2 The pressure is 0.3MPa and the carbonization time is 8h.

[0023] Speci...

Embodiment 7

[0028] The heating temperature of waste cement stone powder is 900℃, the holding time is 2h, and it is cooled with the furnace. The mass ratio of the regenerated cementitious material, water and sand is 1:0.25:1, the curing time is 2h, and the carbonization condition is CO 2 The concentration is greater than 99%, the carbonization pressure is 0.2MPa, and the carbonization time is 8h. The compressive strength of the product is 63MPa, without cracking.

Embodiment 8

[0030] The heating temperature of waste cement stone powder is 900℃, the holding time is 2h, and it is cooled with the furnace. The mass ratio of the regenerated cementitious material, water and sand is 1:0.25:1, the curing time is 2h, and the carbonization condition is CO 2 The concentration is greater than 99%, the carbonization pressure is 0.3MPa, and the carbonization time is 2h. The compressive strength of the product is 66MPa, without cracking.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Compressive strength | aaaaa | aaaaa |

| Compressive strength | aaaaa | aaaaa |

| Compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com