Light weight no-thermal-bridge wood structure sandwich panel

A wood structure and sandwich panel technology, applied in building components, building structures, buildings, etc., can solve problems such as greenhouse effect, acid rain, high energy consumption, air pollution, etc., achieve fast assembly speed, reduce on-site operations, and industrialization. high degree of effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

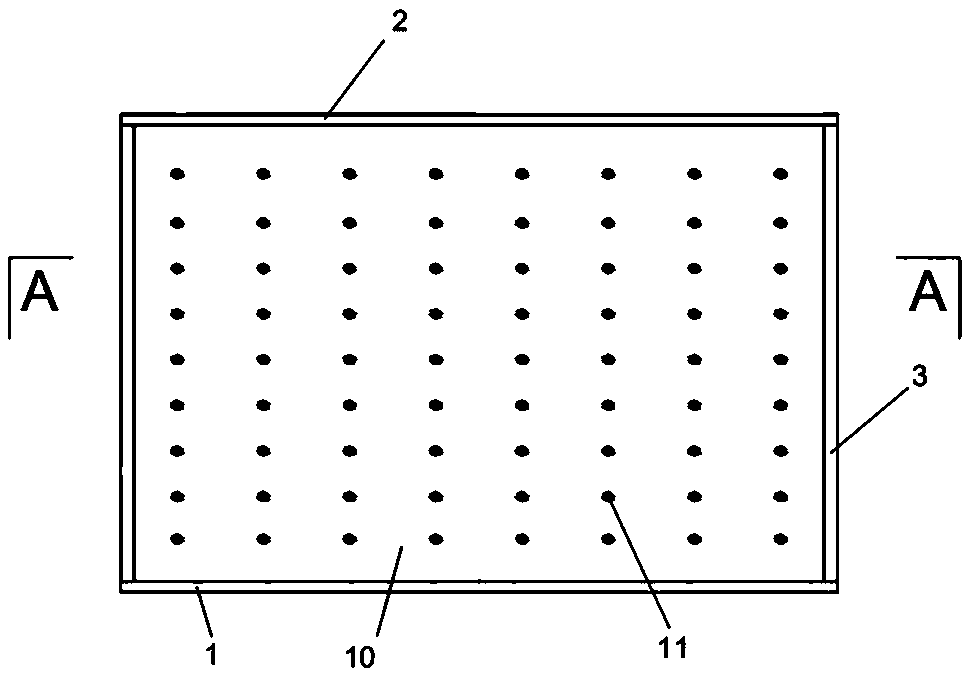

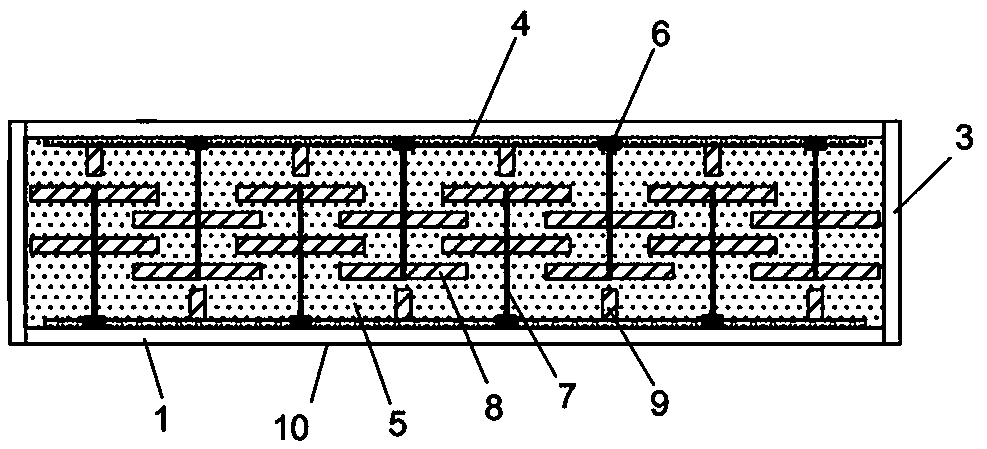

[0018] Example: such as Figure 1 ~ Figure 2 As shown, a lightweight athermal bridge wood structure sandwich panel, including wooden frame bottom plate, wooden frame top plate, wooden frame side plate, light metal plate, sandwich insulation layer, anchor frame installation plate, anchor frame, inner longitudinal Timber studs, internal transverse timber studs, wall plies and nails; lightweight athermal bridge wood sandwich panels set in a rectangular shape with a wooden frame base plate at the bottom, a wooden frame top plate at the top, and wood frame side panels on both sides , the left and right ends of the wooden frame bottom plate and the wooden frame top plate extend to the outer edge of the wooden frame side plate, the two sides of the sandwich panel are wall panels, and the wall panels are preferentially OSB boards, and the nails are evenly distributed on the wall panels. The width of the wooden frame bottom plate, wooden frame top plate, and wooden frame side plates ar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com