Iron-carbon alloy film polymer fiber optical corrosion sensor and preparation method thereof

A technology for corrosion sensors and iron-carbon alloys, which is applied in the fields of weather resistance/light resistance/corrosion resistance, instruments, scientific instruments, etc. It can solve complex problems, high-level production materials and processes, and achieve high sensitivity, easy production, and good adaptability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

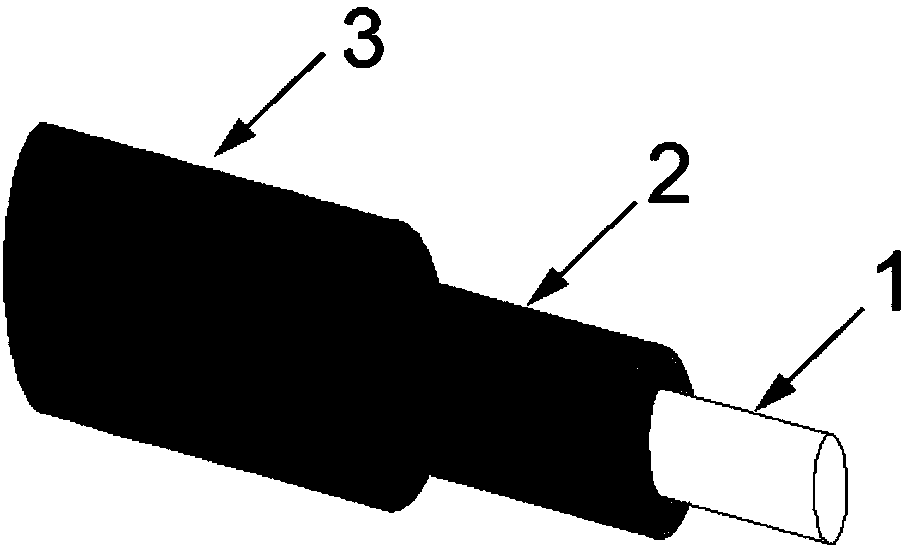

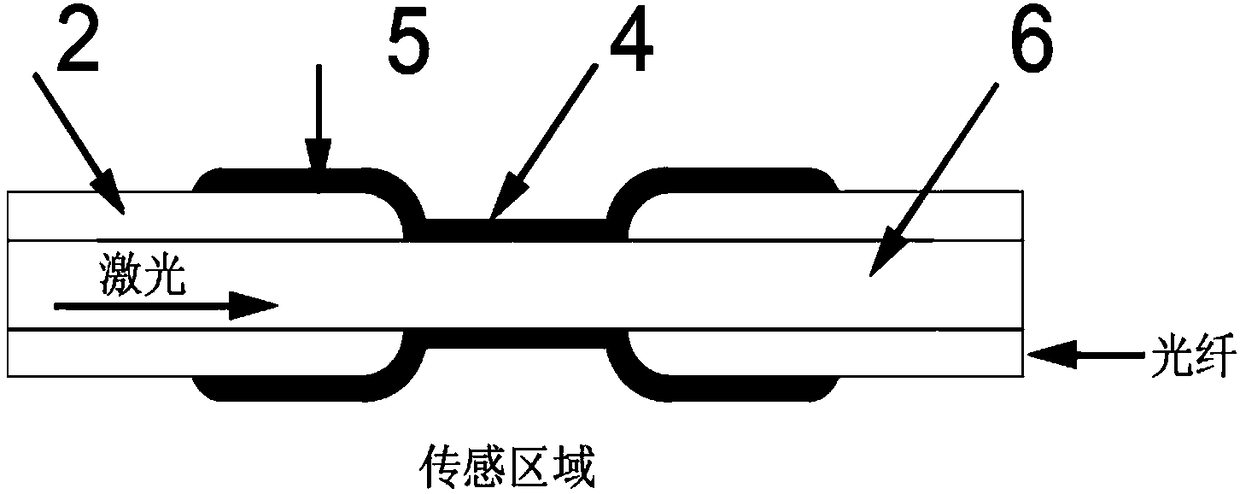

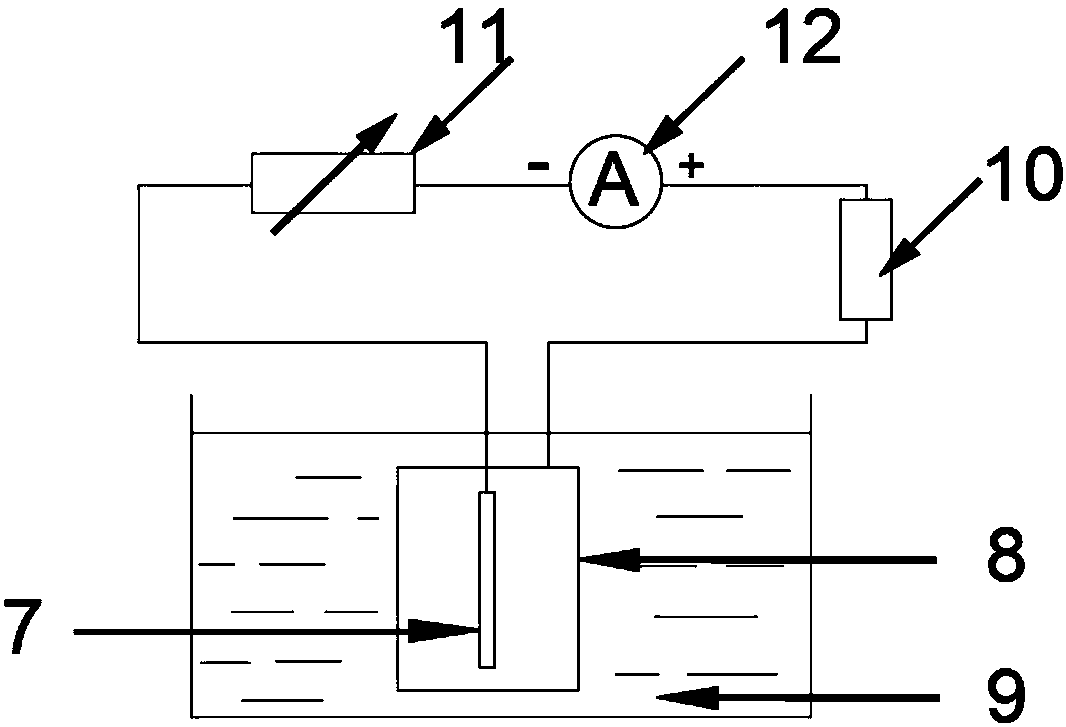

[0058] A preparation method of an iron-carbon alloy film polymer optical fiber corrosion sensor, comprising the following steps:

[0059] S1. Take a section of commercially available polymer optical fiber, use a blade to remove the coating layer of the optical fiber, and the length of the exposed cladding and fiber core is 6-10 cm;

[0060] From the point of view of the manufacturing process of the sensor, it is generally hoped that the thicker the optical fiber, the better. An optical fiber that is too thin is prone to breakage during the manufacturing process. But judging from the actual production process, as long as it is operated properly, thin optical fibers can also achieve better results. Moreover, the thick optical fiber also has the characteristics of poor flexibility and not easy to bend. Therefore, it is not advisable to use too thick or too thin optical fibers in the sensor manufacturing process. Therefore, the present invention adopts a polymer optical fiber wi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com