High-solid-solubility multi-principal-component alloy screening method

A multi-principal alloy and screening method technology, which is applied in the field of rapid screening of high solid-solubility multi-principal alloys, can solve problems such as poor compositional uniformity, and achieve the effect of reducing research and development costs and cycles

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be further described below in conjunction with the accompanying drawings.

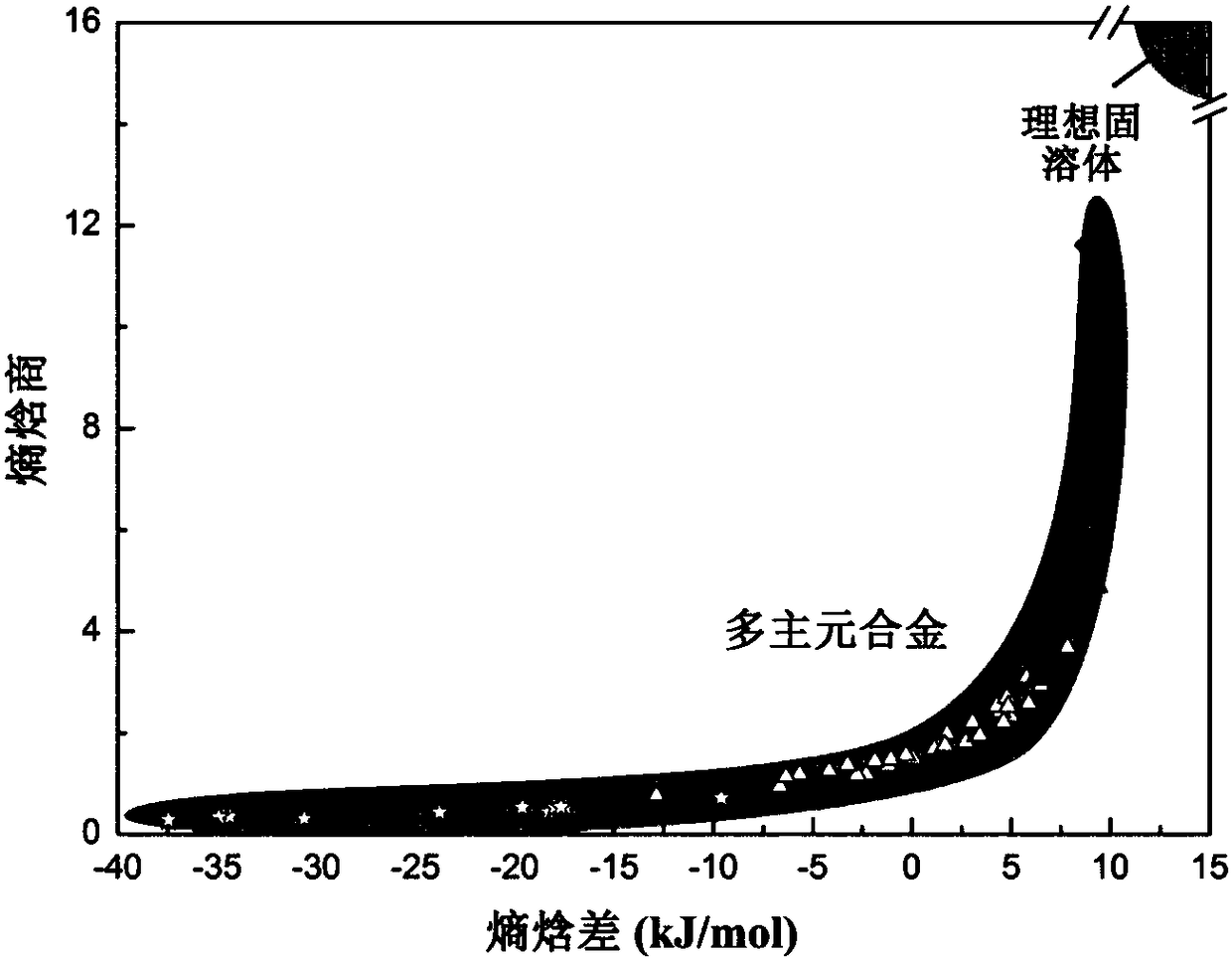

[0029] figure 1 It is the classification and summary of the existing alloy systems in the present invention. Different symbols in the figure represent different types of alloys, and solid symbols represent materials with better solid solution properties. From the left to the right are amorphous alloy materials, High-entropy alloy materials, iron-rich high-entropy alloy materials.

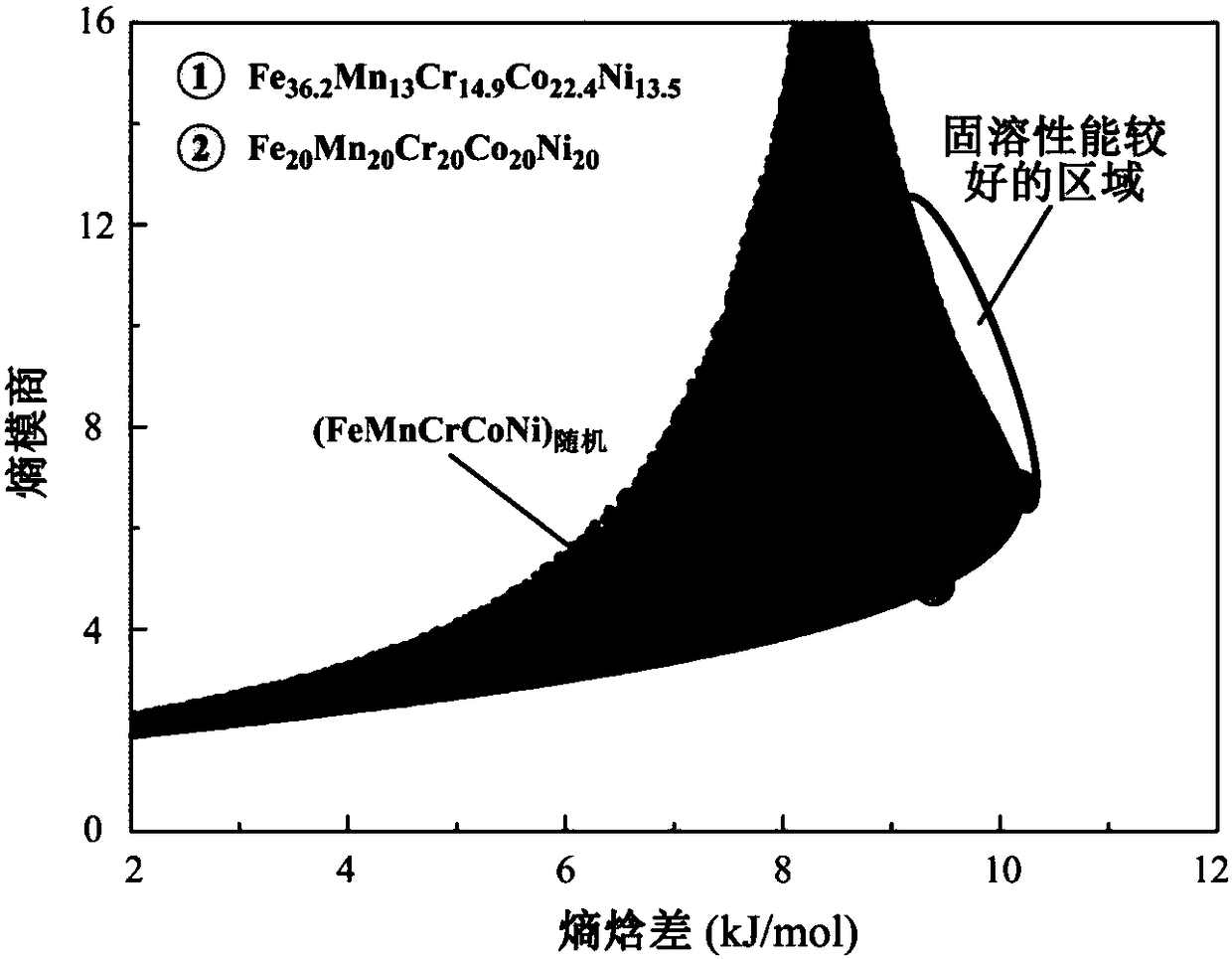

[0030] Application of a rapid screening method for multi-principal alloys in the Fe-Mn-Cr-Co-Ni system:

[0031] (1) According to the requirements of material performance design, select Fe, Mn, Cr, Co and Ni as the basic units of material design, and establish the basic database of related elements through literature data and calculation;

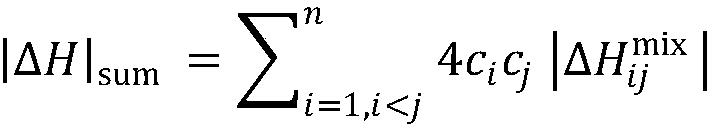

[0032] (2) Use the Monte Carlo method to generate a large number of random numbers. In order to traverse various possible alloy compositions, the amoun...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com