High-temperature solid solution process for 2A14 aluminum alloy ring piece

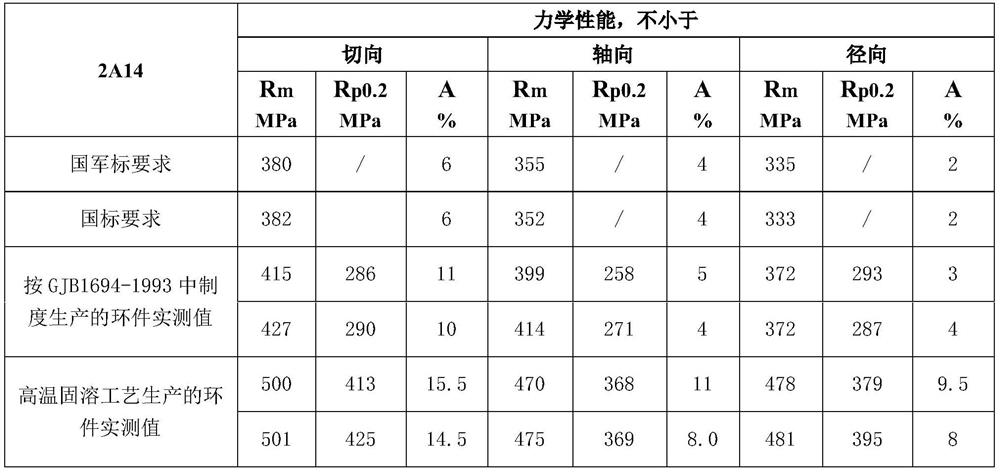

A 2A14, aluminum alloy technology, which is applied in the field of high-temperature solid solution process of 2A14 aluminum alloy rings, can solve problems such as unsatisfactory and unreachable high index requirements, and achieve the effects of improving product performance, good solid solution effect, and avoiding overheating

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

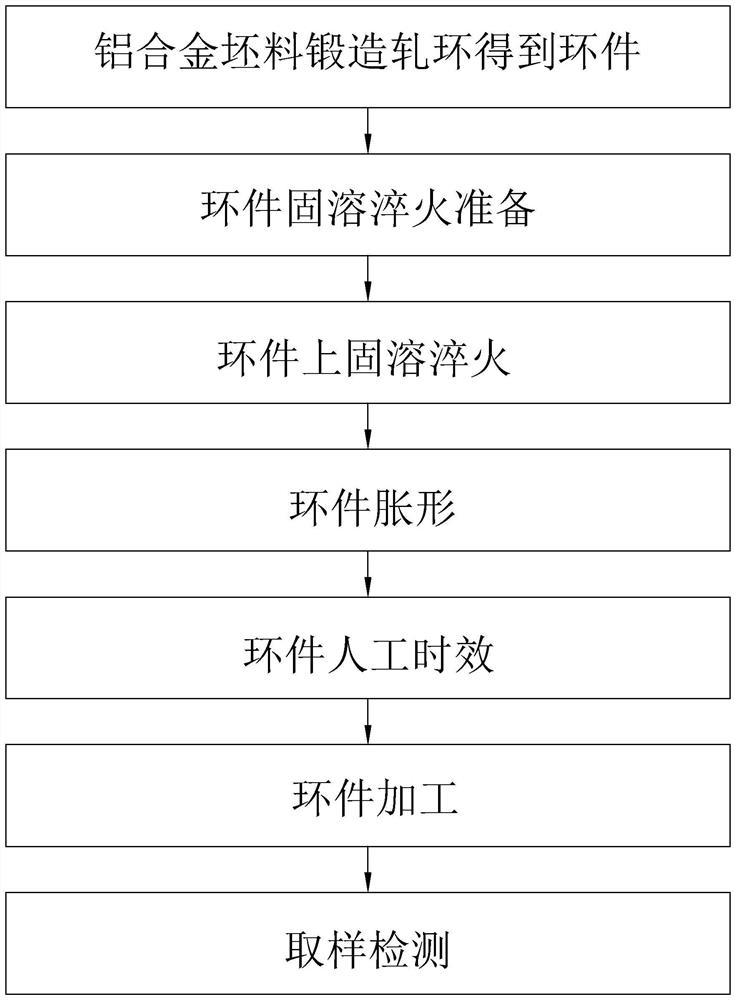

[0019] Embodiment: a kind of 2A14 aluminum alloy ring part high-temperature solid solution process, such as figure 1 shown, including the following steps:

[0020] S1. The ring is obtained by forging and rolling the aluminum alloy billet, and the specific size of the ring is Φ2030×Φ1740×650 mm.

[0021] S2. Ring piece solid solution quenching preparation: put the ring piece into the new line solid solution furnace, fix 4 external thermocouples on the ring piece, and fix the external thermocouples by binding iron wires. 4 external thermocouples are distributed in 4 positions of east, south, west and north to ensure that the temperature of the ring can be detected in all directions.

[0022] S3. Solution quenching and real-time temperature control on the ring parts: the furnace is fixed at 509°C, and then the temperature is raised by power transmission, and the temperature rises to 509°C in 1.5 hours, and the temperature displayed by the solid solution furnace instrument shall ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com